Supercharger, exhaust aftertreatment system and control method thereof

An exhaust aftertreatment and supercharger technology, applied in the field of vehicles, can solve the problems of shortened, insignificant, and unsatisfactory emission effect of the catalytic converter, so as to shorten the light-off time, reduce temperature loss, and reduce exhaust gas. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

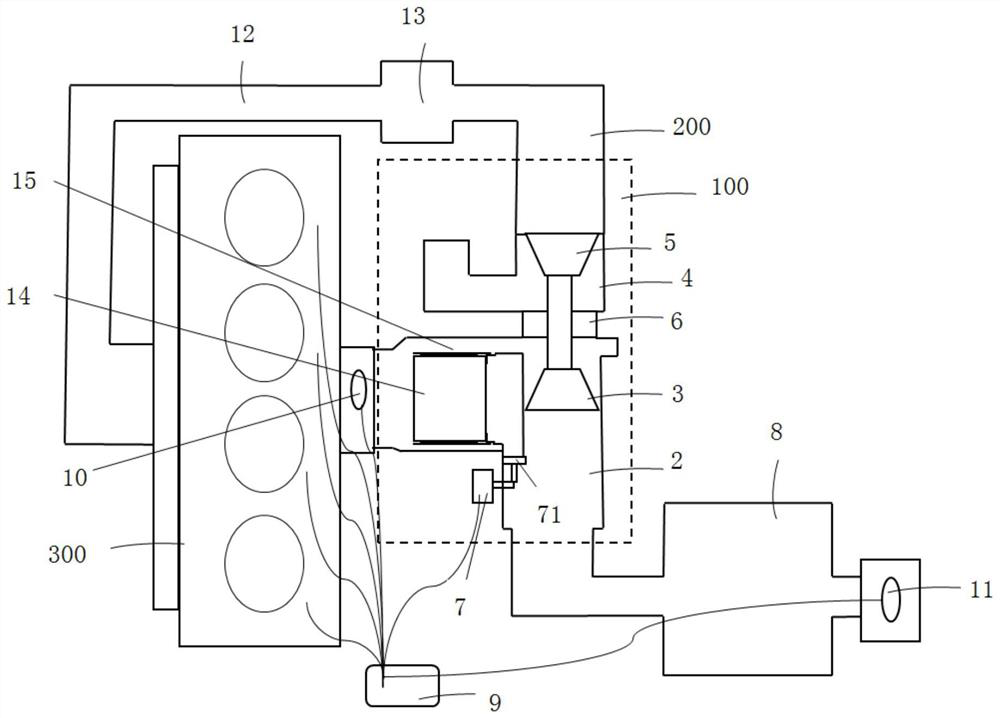

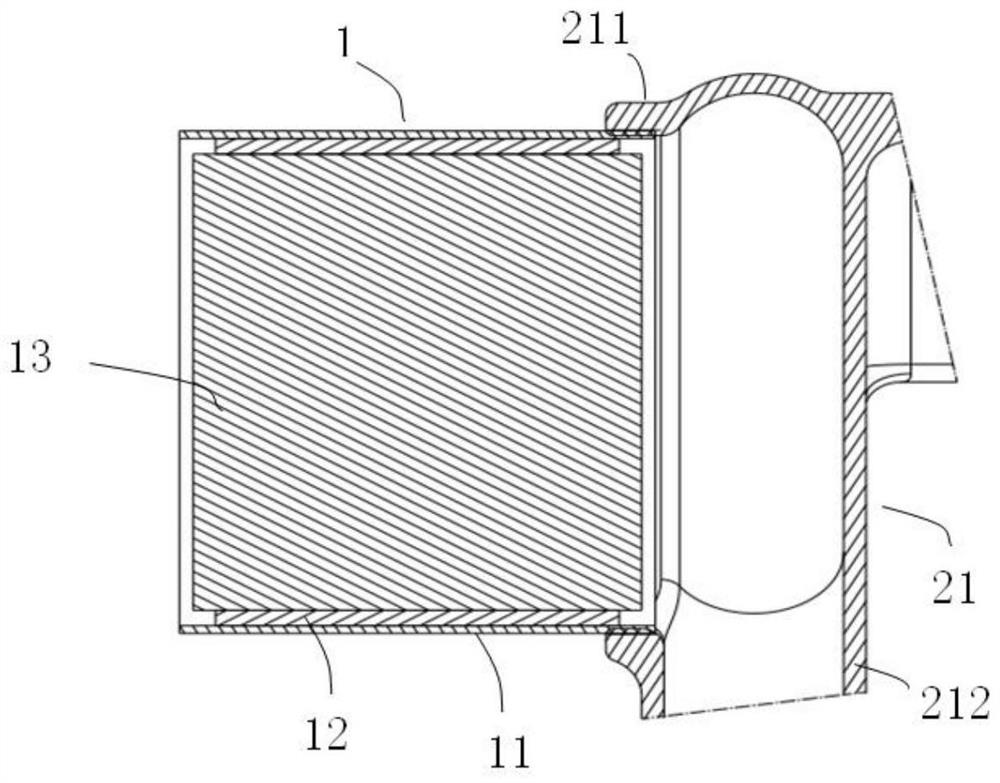

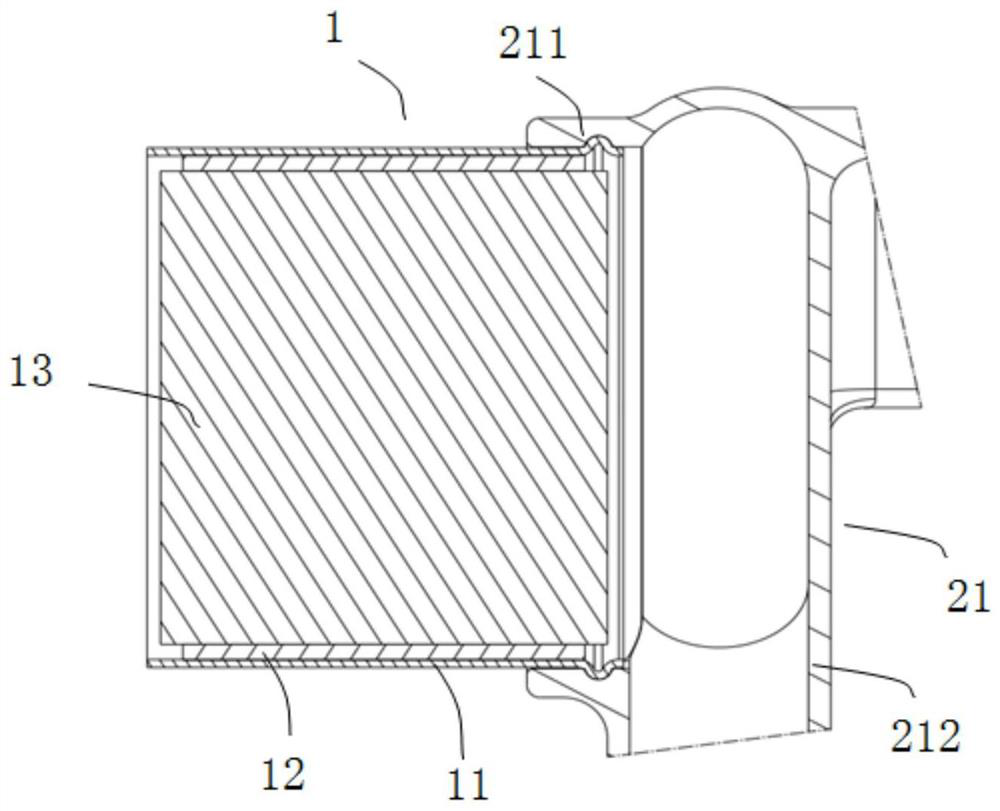

[0027] The technical solutions herein will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific embodiments described here are only used for explaining the text, rather than limiting the text.

[0028] Existing superchargers for automobiles are a technology that pre-compresses air before it is supplied into cylinders to increase air density and intake air volume. The purpose is to increase the inflation volume, increase power, improve economy, and improve emissions.

[0029] Superchargers can be divided into three categories according to the different power sources provided, exhaust gas turbocharger, mechanical turbocharger, and electric auxiliary turbocharger. Compress air through the supercharger to increase the air intake density of the engine, thereby increasing the engine's power per liter. At the same time, because the mixed combustion regulation of the engine has been improved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com