Light-emitting diode packaging structure

A light-emitting diode and packaging structure technology, applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve the problem that the light source cannot be effectively concentrated, the light-emitting diode packaging component has no mechanism design, and the light cannot be accurately aligned with the lens design of the optical system of the projector, etc. problem, to achieve the effect of avoiding light divergence and good light utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

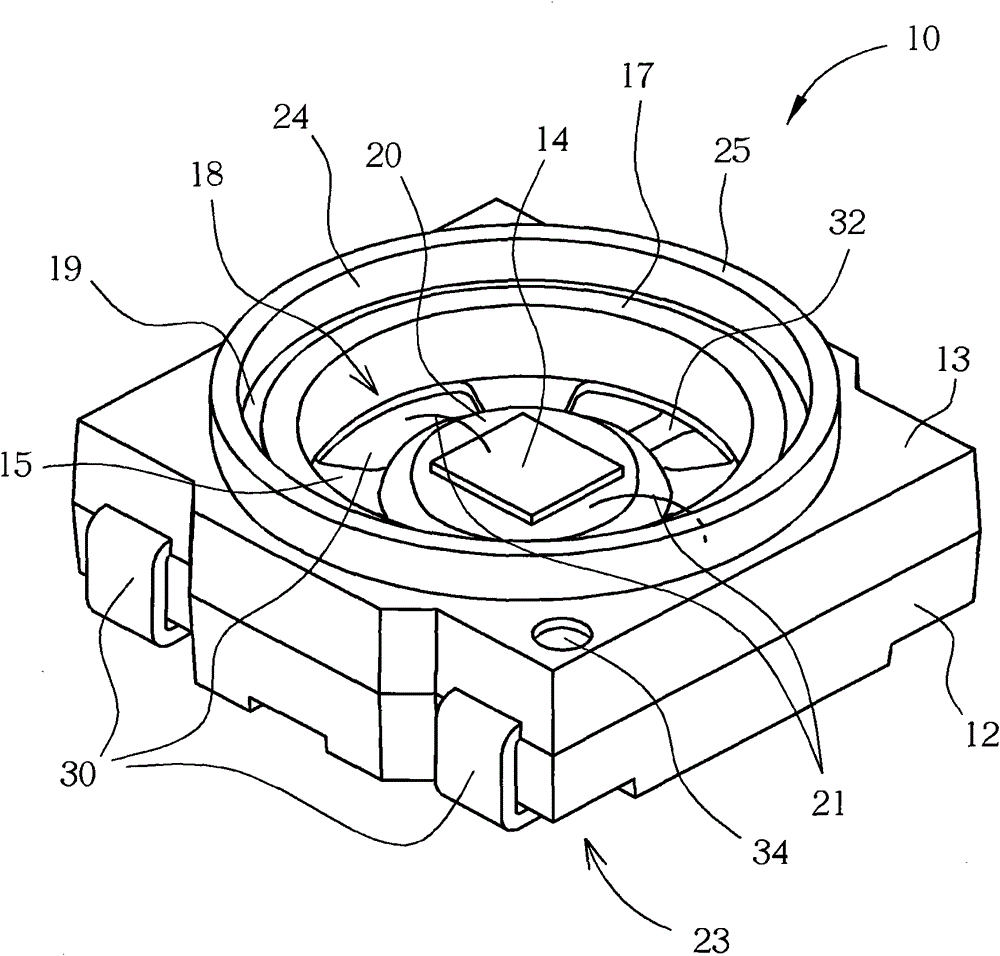

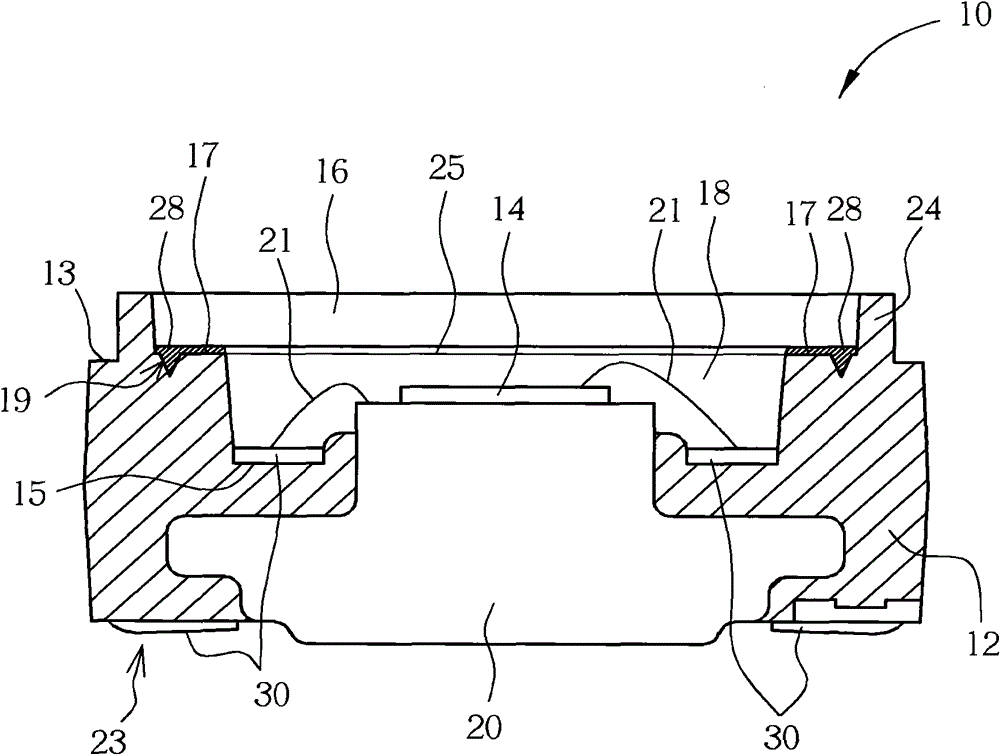

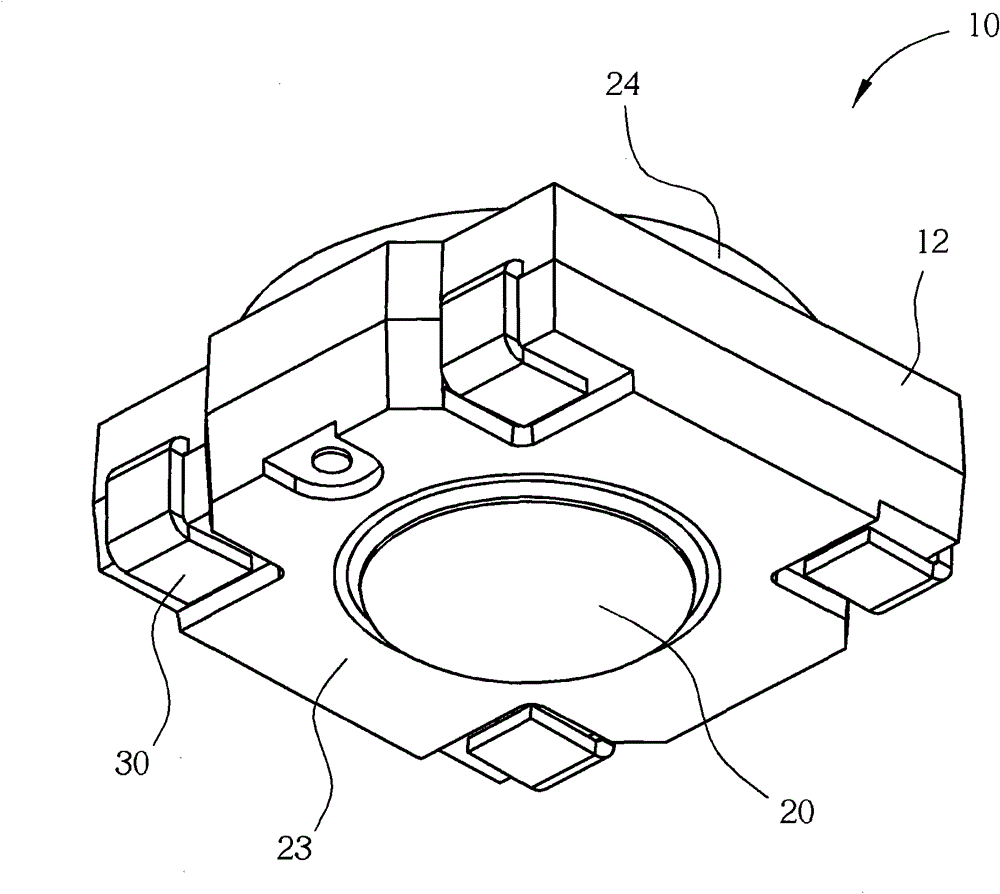

[0023] Please refer to Figure 1 to Figure 3 , figure 1 , figure 2 and image 3 They are the upper side appearance schematic diagram, the cross-sectional schematic diagram and the lower side appearance schematic diagram of Embodiment 1 of the light emitting diode packaging structure of the present invention, respectively. The LED packaging structure 10 of the present invention can be applied in a projector to be used as a projection light source. The LED package structure 10 includes a package case 12 , at least one LED chip 14 , a transparent component 16 and a heat dissipation block 20 . The package case 12 has an upper surface 13 and a groove 18 , wherein the groove 18 is disposed on the upper surface 13 of the package case 12 , that is, the groove 18 is disposed in the package case 12 and exposed by the upper surface 13 . The groove 18 has a bottom surface 15 and an opening 25 . The heat dissipation block 20 is disposed on the bottom surface 15 of the groove 18 , ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com