Bra mold cup and manufacturing process thereof

A technology of manufacturing crafts and mold cups, which is applied to bras, clothing, brassieres, etc., and can solve problems such as wearing breast injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

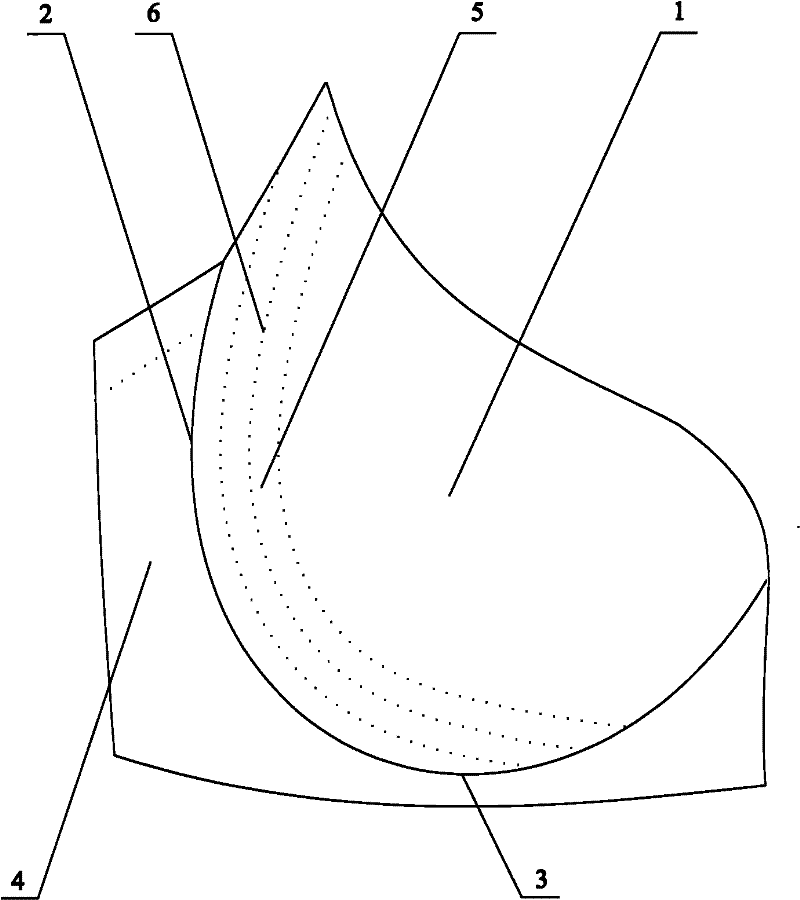

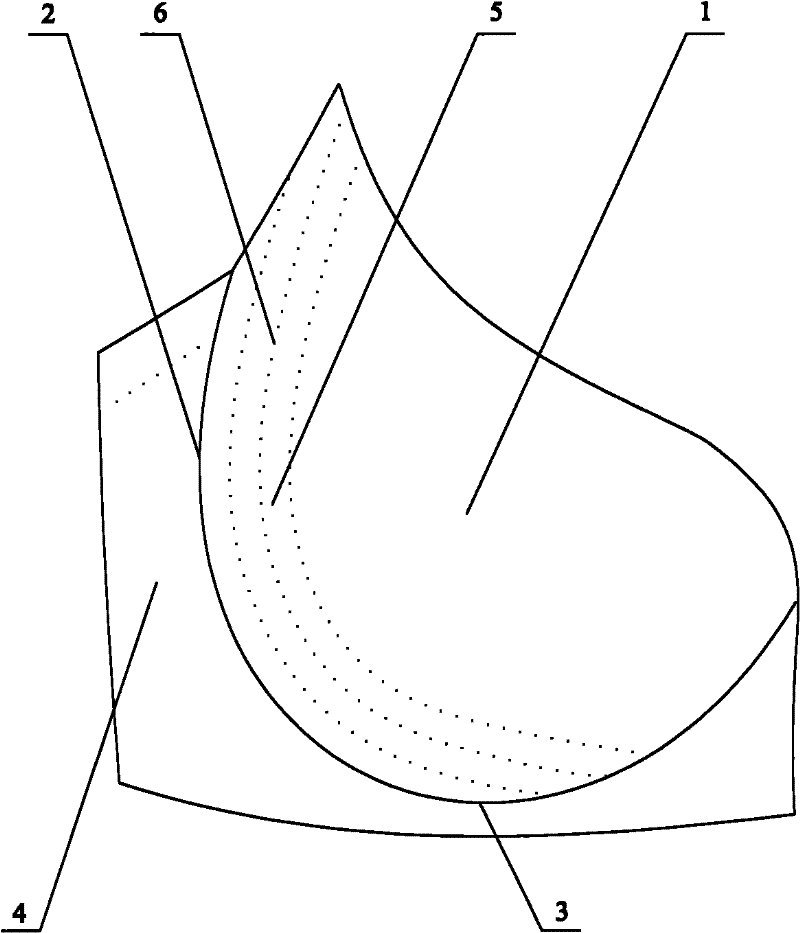

[0020] Embodiment one: see attached figure 1 shown.

[0021] A bra mold cup comprises a mold cup body 1, the mold cup body 1 includes a bowl side 2 and a lower bowl circumference 3, the bowl side 2 is fixedly connected with a side ratio 4, and the side ratio 4 is slightly higher than that of an ordinary bra mold cup, The mold cup body 1 is provided with three Jiamei 5s with a semicircular cross-section. The Jiamei 5 extends from the bowl side 2 to the lower bowl circumference 3. The Jiamei 5 is arc-shaped and adapts to the mold cup body 1. Two adjacent Jiamei 5s There is a groove 6 between them.

[0022] A manufacturing process of the bra mold cup as described above, comprising the steps of:

[0023] (1) After bonding the sponge to the fabric, cut out the upper layer and the lower layer according to the design;

[0024] (2) The upper layer is processed with cotton cutting technology, and the upper layer is cut out of the Jiamei extending from the side of the bowl to the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com