Cutter head mechanism for processing strengthened fin heat-exchange tube and operation method thereof

A technology of heat exchange tubes and cutterheads, which is applied in metal processing equipment, routers, manufacturing tools, etc., can solve the problems of inability to guarantee the mass production and quality of heat exchangers, insufficient strength of the root of warp blades, and easy fall off of warp blades, etc. problem, to achieve the effect of simple structure, low production cost and simple manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

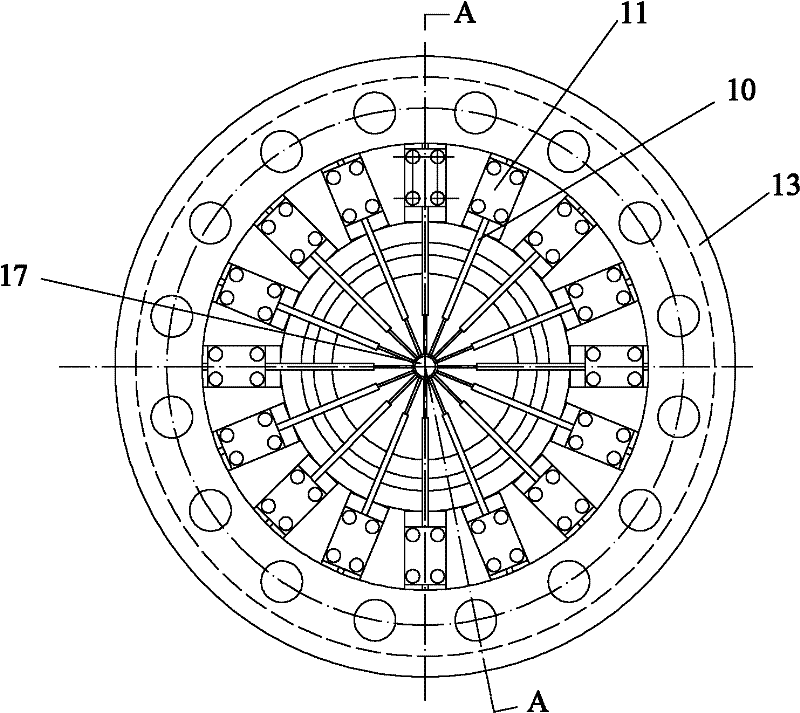

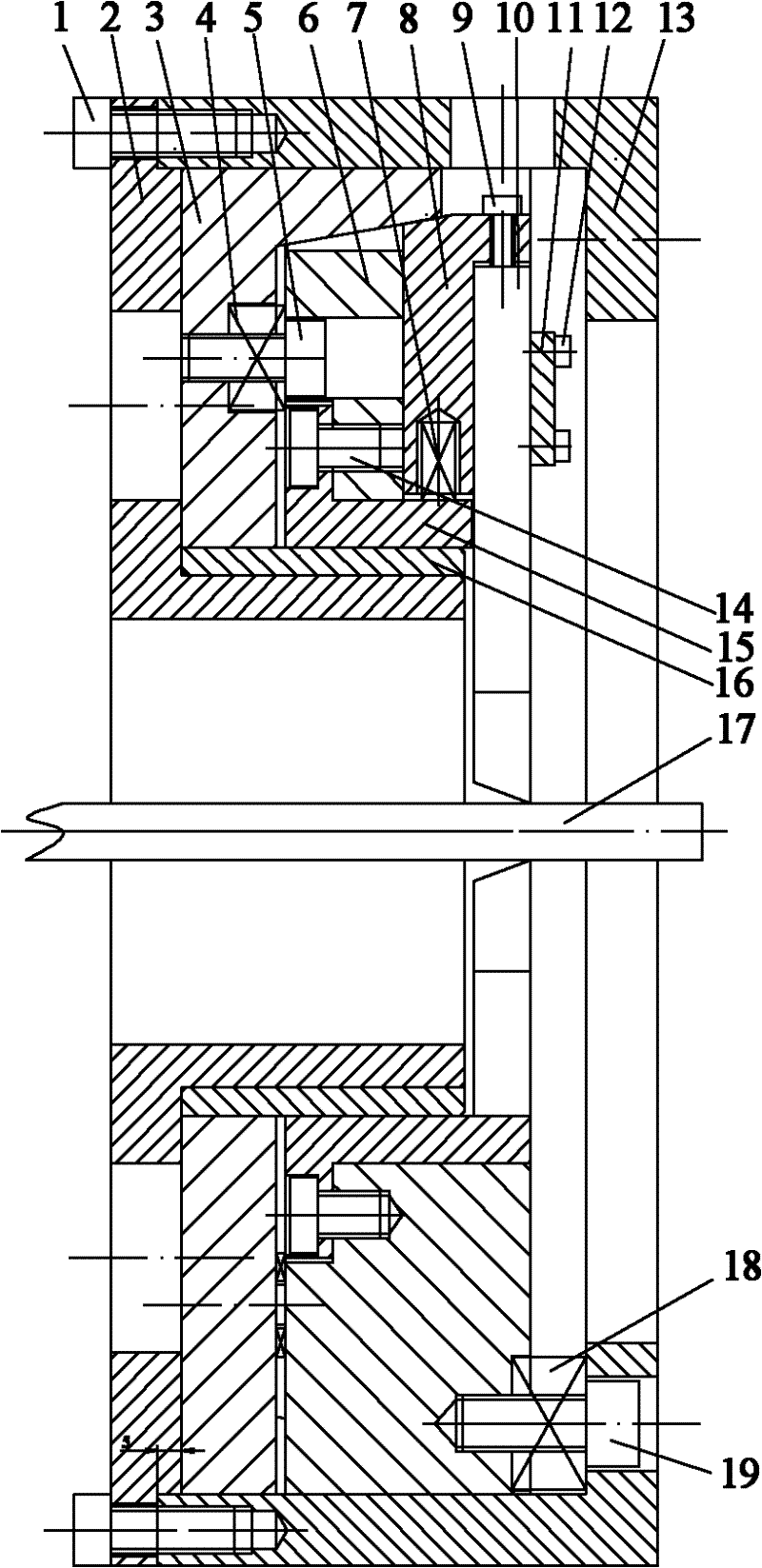

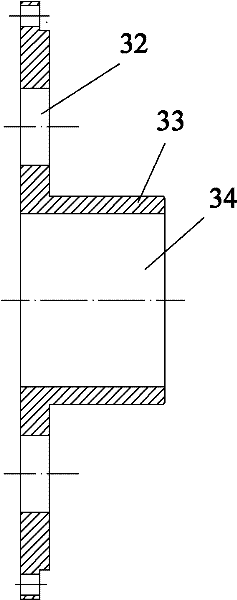

[0038] Figure 1 to Figure 10 Shows the specific structural diagram of this embodiment, such as figure 2 As shown, the enhanced blade heat exchange tube processing cutter head mechanism includes an end cover 2, a push plate mechanism, a cutter head 6, sixteen sliders 8, a shaft sleeve 16, a support sleeve 15 and a cutter head jacket 13. Cover 2 is fixedly connected with cutterhead outer cover 13, as image 3 As shown, the inner circumference of the end cover 2 is a boss 33, and the shaft sleeve 16 cooperates with the outer circumference of the boss 33; cavity; the push plate mechanism, cutter head 6, and sixteen sliders 8 are sequentially placed in the cavity, and the push plate mechanism is connected with cutter head 6 and sixteen slide blocks 8 respectively; the push plate mechanism Cooperate and connect with the inner wall of the end cover 2; the inner circumference of the push plate mechanism and the support sleeve 15 are all matched with the outer circumference of the ...

Embodiment 2

[0056] This embodiment has the same structure as Embodiment 1 except the following features: the gap between the outer end surface of the cutter head and the inner end face of the cutter head groove is 2mm.

[0057] The slope of the side wall of the cutter head groove is 30 degrees; the diameter of the primary hole of the stepped hole on the push plate is 10 mm larger than the diameter of the secondary hole.

[0058] The size of the gap between the inner end surface of the cutter head casing and the end surface of the protrusion is 0.35mm.

[0059] The diameter of the primary hole of the stepped hole of the cutterhead is 10 mm larger than the diameter of the secondary hole.

[0060] The axle sleeve is a cast iron sleeve.

[0061] The number of the bumps, the number of slide block grooves, the number of planers, the number of slide blocks, the number of push plate springs, the number of bolts of the push plate mechanism, and the number of holes of the cutter head Twenty respe...

Embodiment 3

[0063] The structure of this embodiment is the same as that of Embodiment 1 except the following features: the gap between the outer end surface of the cutter head and the inner end face of the cutter head slot is 1.5mm.

[0064] The inclination of the side wall surface of the cutter head groove is 15 degrees; the diameter of the primary hole of the stepped hole on the push plate is 8 mm larger than that of the secondary hole.

[0065] The size of the gap between the inner end surface of the cutter head casing and the end surface of the protrusion is 0.25mm.

[0066] The diameter of the primary hole of the stepped hole of the cutter head is 8 mm larger than the diameter of the secondary hole.

[0067] The number of the bumps, the number of slide block grooves, the number of planers, the number of slide blocks, the number of push plate springs, the number of bolts of the push plate mechanism, and the number of holes of the cutter head Fifteen respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com