Tool head positioning structure of head shaking wrench

A technology of positioning structure and tool head, which is applied in the field of oscillating wrench, can solve the problems of inaccurate positioning, limited stability, displacement of the control rod 71, etc., and achieve accurate and stable positioning or swing, high holding stability, and improved stability degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

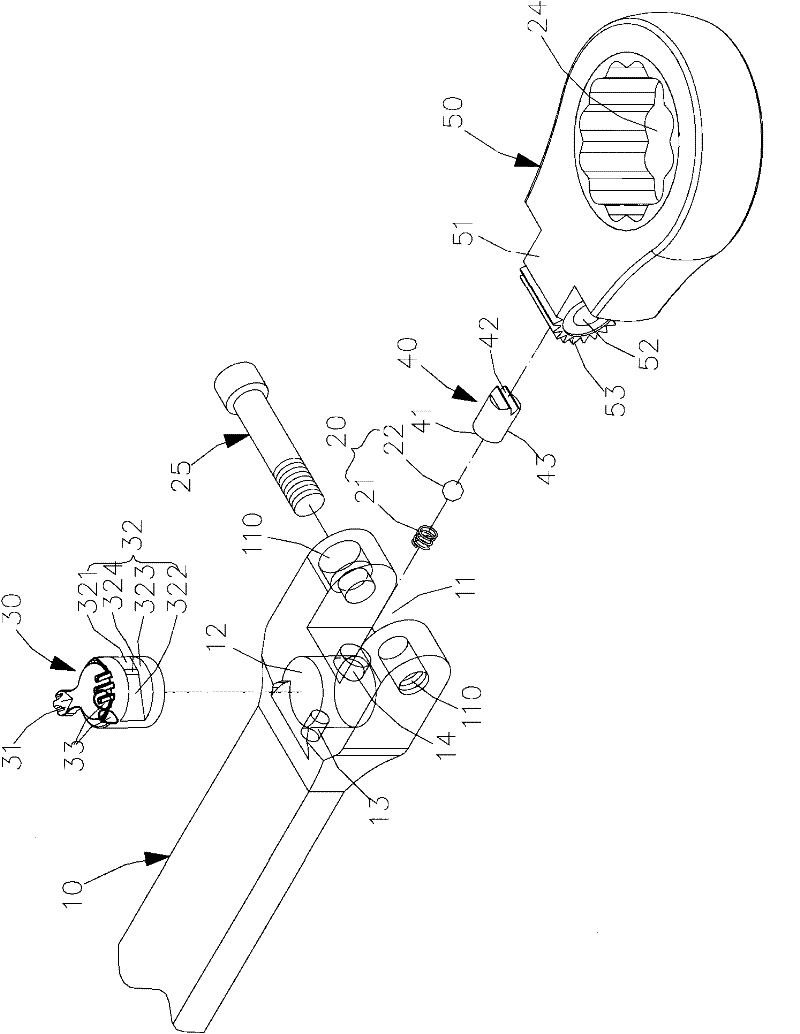

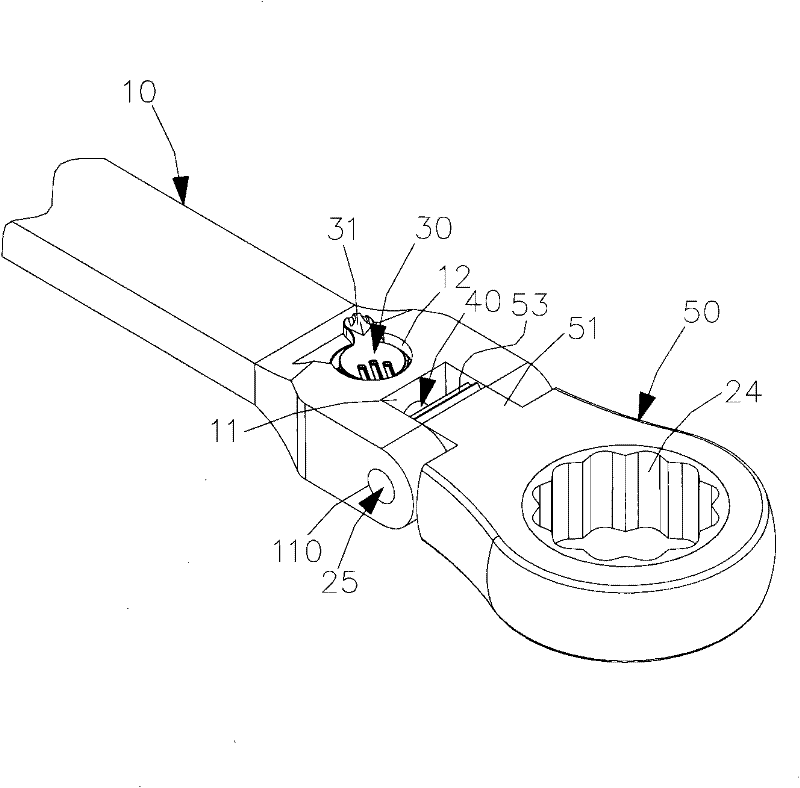

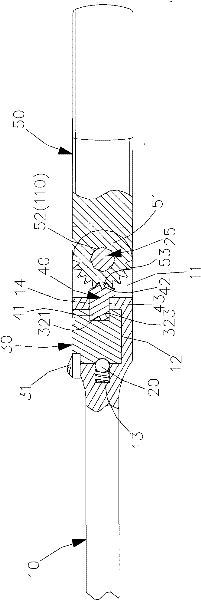

[0026] An embodiment of the tool head positioning structure of the shaking head wrench of the present invention is as follows: figure 1 , figure 2 , image 3 shown, including:

[0027] One end of a handle 10 is pivotally provided with a tool head 50, and the tool head 50 is provided with a convex fitting portion 51 at the pivot point. Along the same circle center as the pivot hole 52, an engaging portion 53 with a plurality of tooth shapes is provided, and a tool portion 24 is additionally provided on the tool head 50, and the tool portion 24 is a matching screw, nut or tool head;

[0028] The handle 10 is provided with a concave pivot joint 11 at the pivot joint between one end and the tool head 50 for the fitting part 51 of the tool head 50 to be inserted into. The two side walls of the pivot joint 11 are provided with horizontal The through pivot hole 110 is aligned with the pivot hole 52 of the matching portion 51 to cooperate with a shaft bolt 25 to pass through and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com