Regulating method of gap between blade and knife door of filament cutter

An adjustment method and shredding machine technology, applied in the field of tobacco machinery, can solve problems such as difficult quantification, errors, and taking up a lot of production time, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

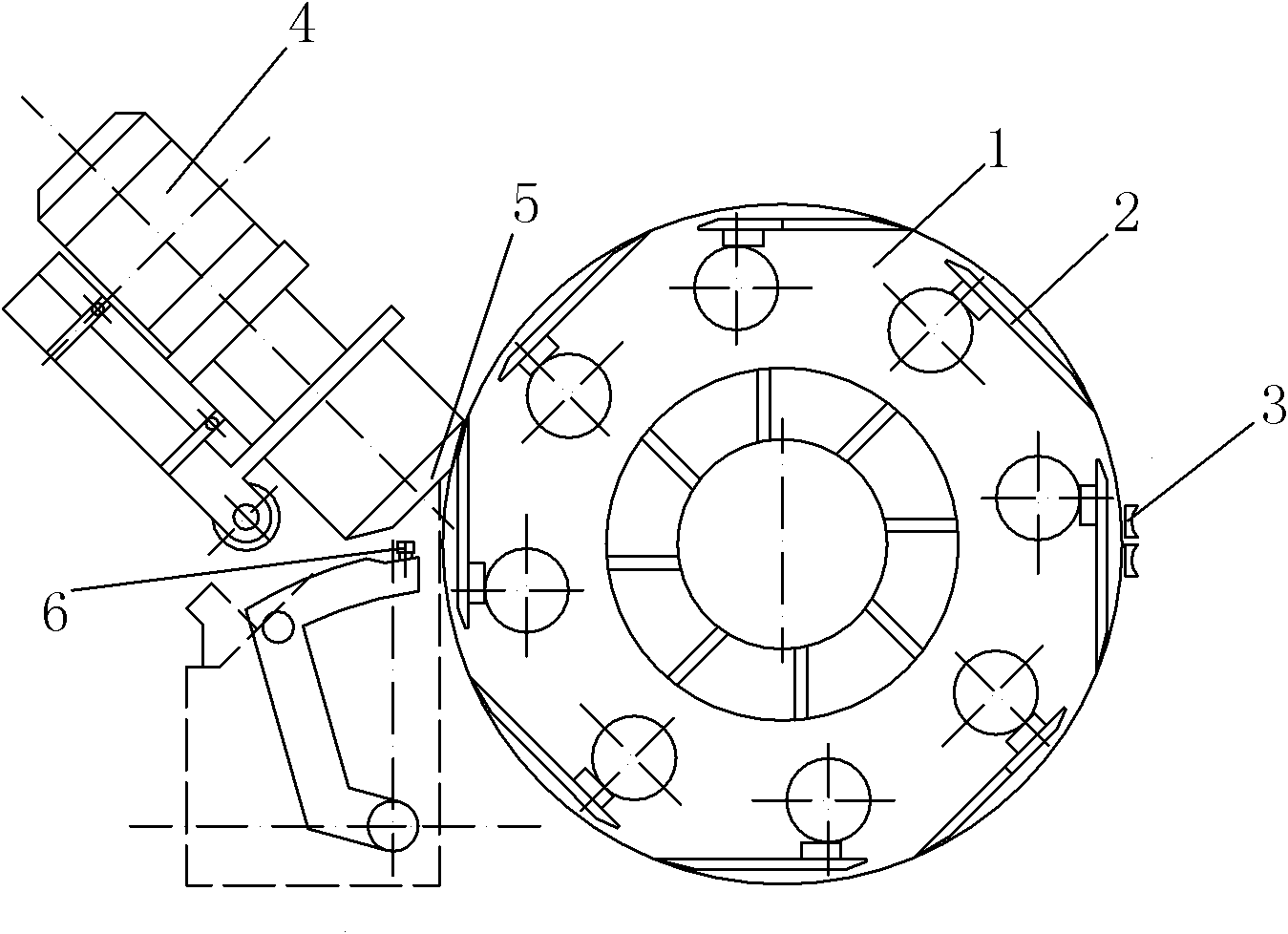

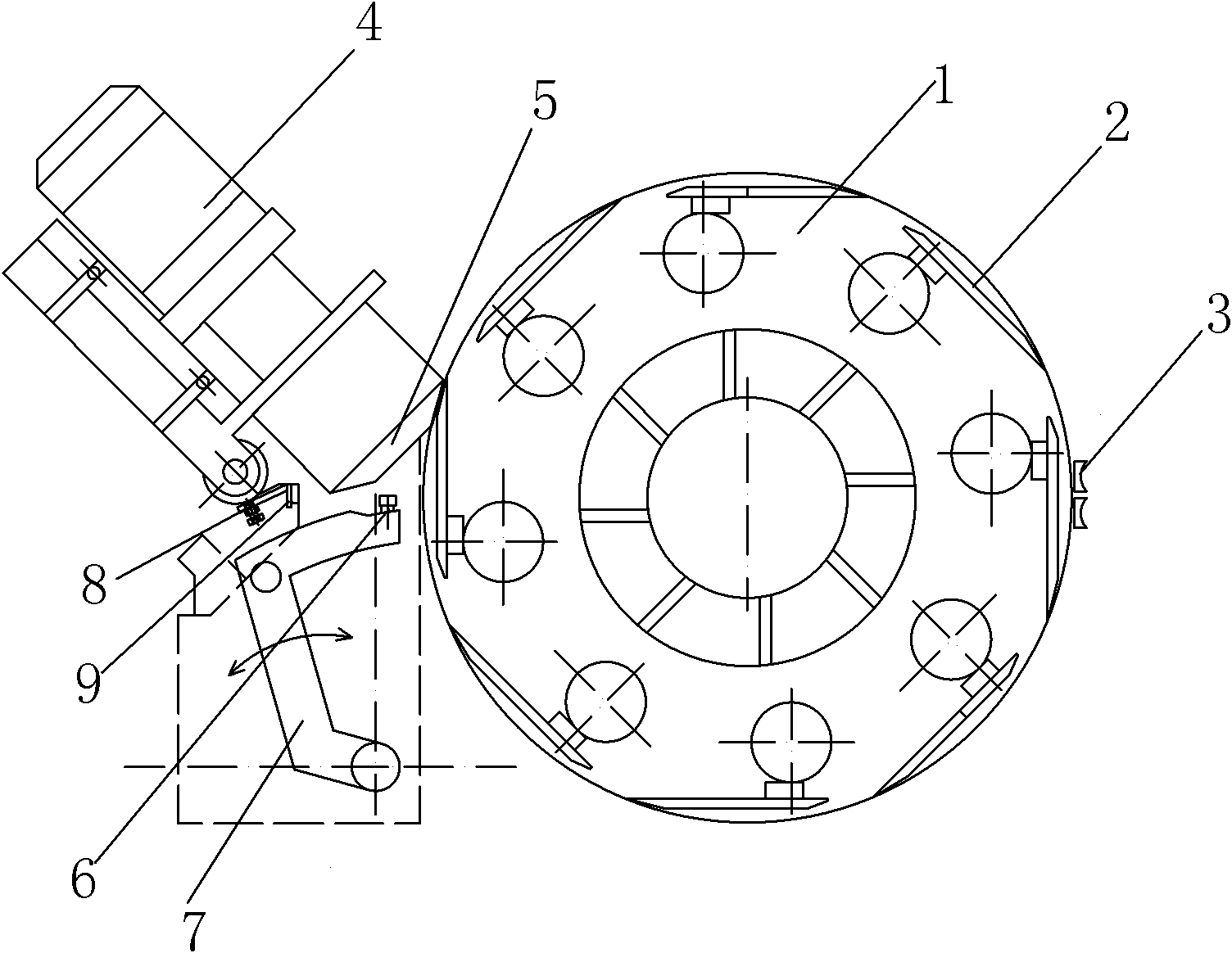

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

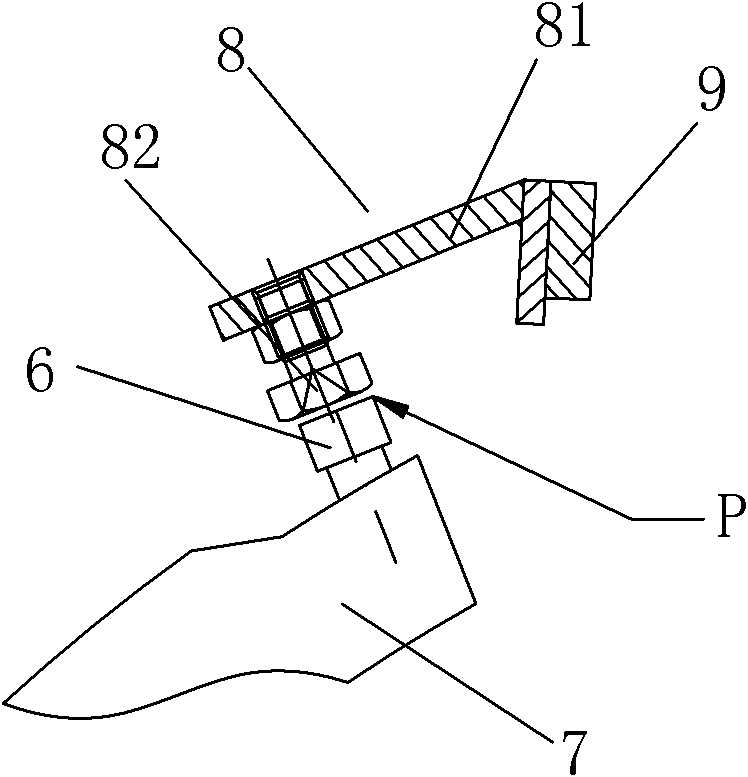

[0020] Such as figure 2 , 3 As shown, the method for adjusting the gap between the cutter blade and the knife gate is adopted. First, a diamond positioning device 8 is fixed on the grinding wheel mechanism of the thread cutter. The diamond positioning device 8 includes a connecting rod 81 and a positioning screw 82. The positioning screw 82 is located at the tail of the connecting rod 81, and the connecting rod 81 is connected with the grinding wheel observation window bead 9 on the grinding wheel mechanism. At the same time, connect the diamond drill 6 of the wire cutter to a connecting swing arm 7 that can move back and forth in a threaded manner. The swing arm 7 can make the diamond drill 6 correspond to the position of the positioning screw 82, and the axis of the positioning screw 82 is aligned with the diamond drill. 6 The turning cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com