Dobby shedding device suitable for ripple-shedding loom

A technology of opening device and dobby, which is applied in the field of weaving machinery, can solve the problems of structural limitation, high price, labor and time-consuming, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

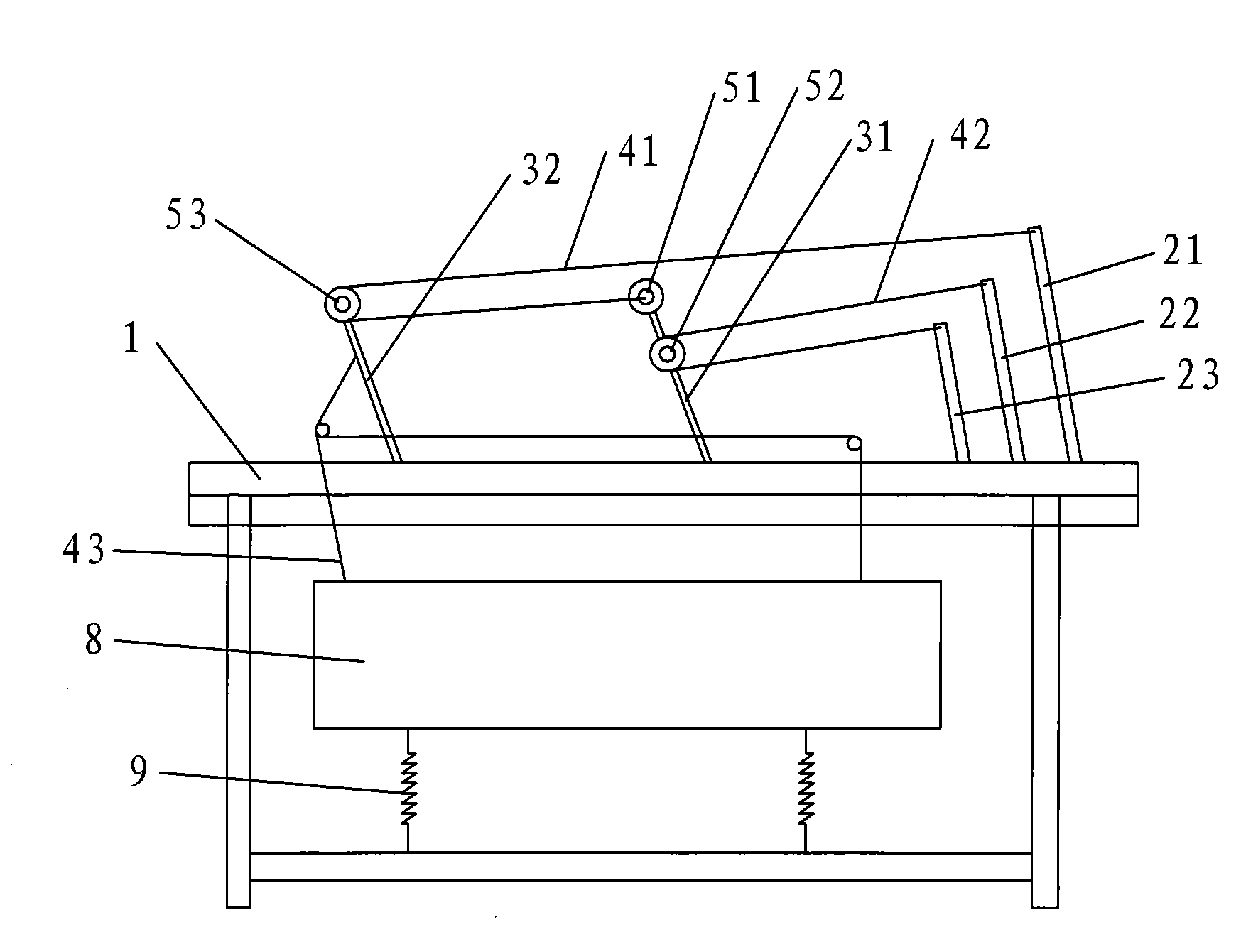

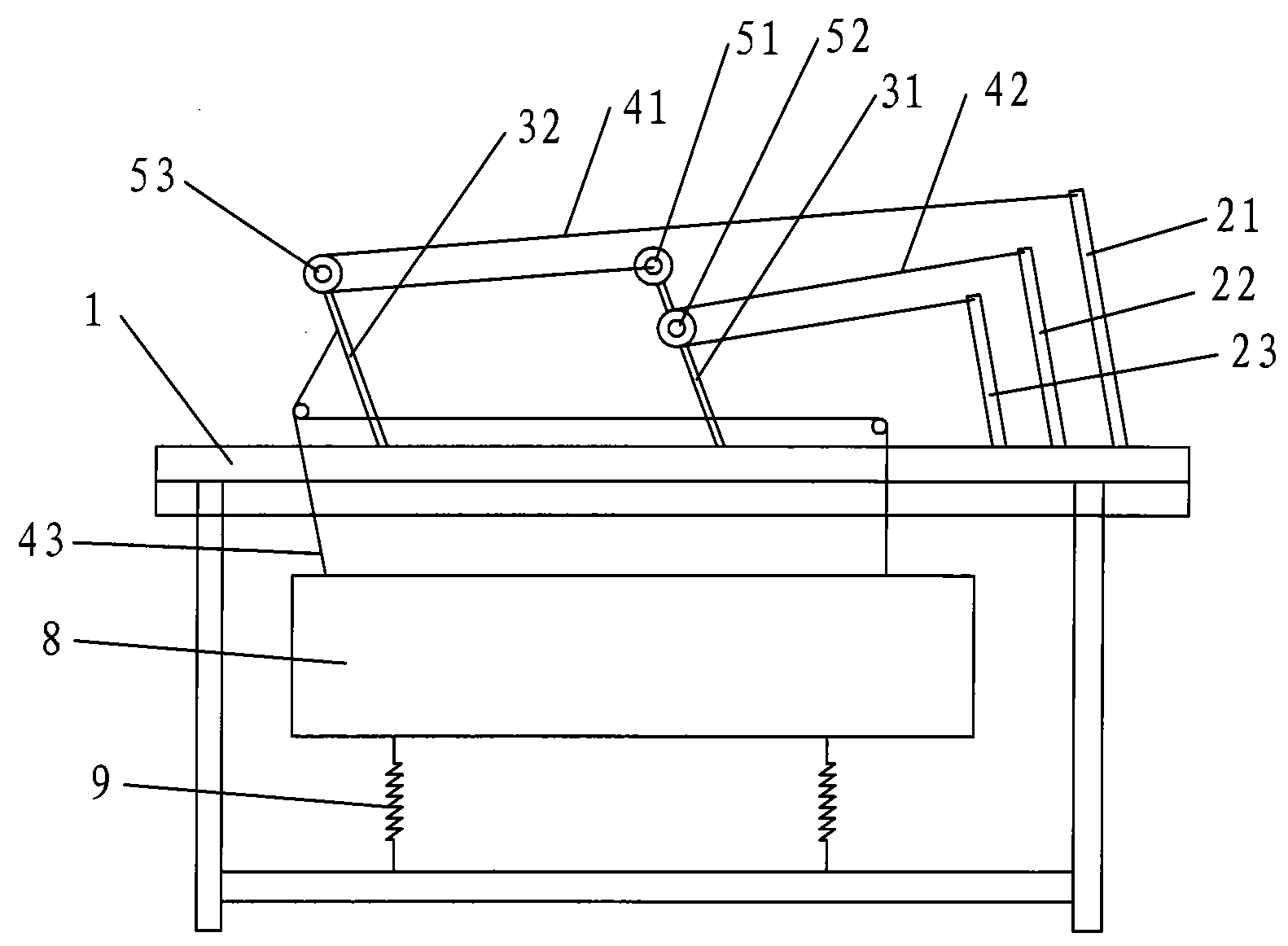

[0011] as attached figure 1 , what the present invention relates to is a kind of dobby shedding device suitable for multi-shed loom, it can make the suture warp heald frame in weaving five-layer cloth, that is, the suture warp produce six warp yarn positions up and down to form five sheds, the The device includes a frame 1, a plurality of seam heald frames 8, a plurality of first driving mechanisms corresponding to the plurality of seam heald frames 8, a plurality of ground warp heald frames, and a plurality of ground warp heald frames one by one. Corresponding to several second driving mechanisms, the first driving mechanism and the second driving mechanism are both arranged on the frame 1 . The corresponding first driving mechanism that drives each seam through the heald frame 8 all includes the first heald lifting arm 21, the second heald lifting arm 22, the third heald...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com