Display apparatus and manufacturing method therefor, and active matrix circuit board

A technology for a display device and a manufacturing method, applied to identification devices, static indicators, instruments, etc., capable of solving problems such as deterioration of display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

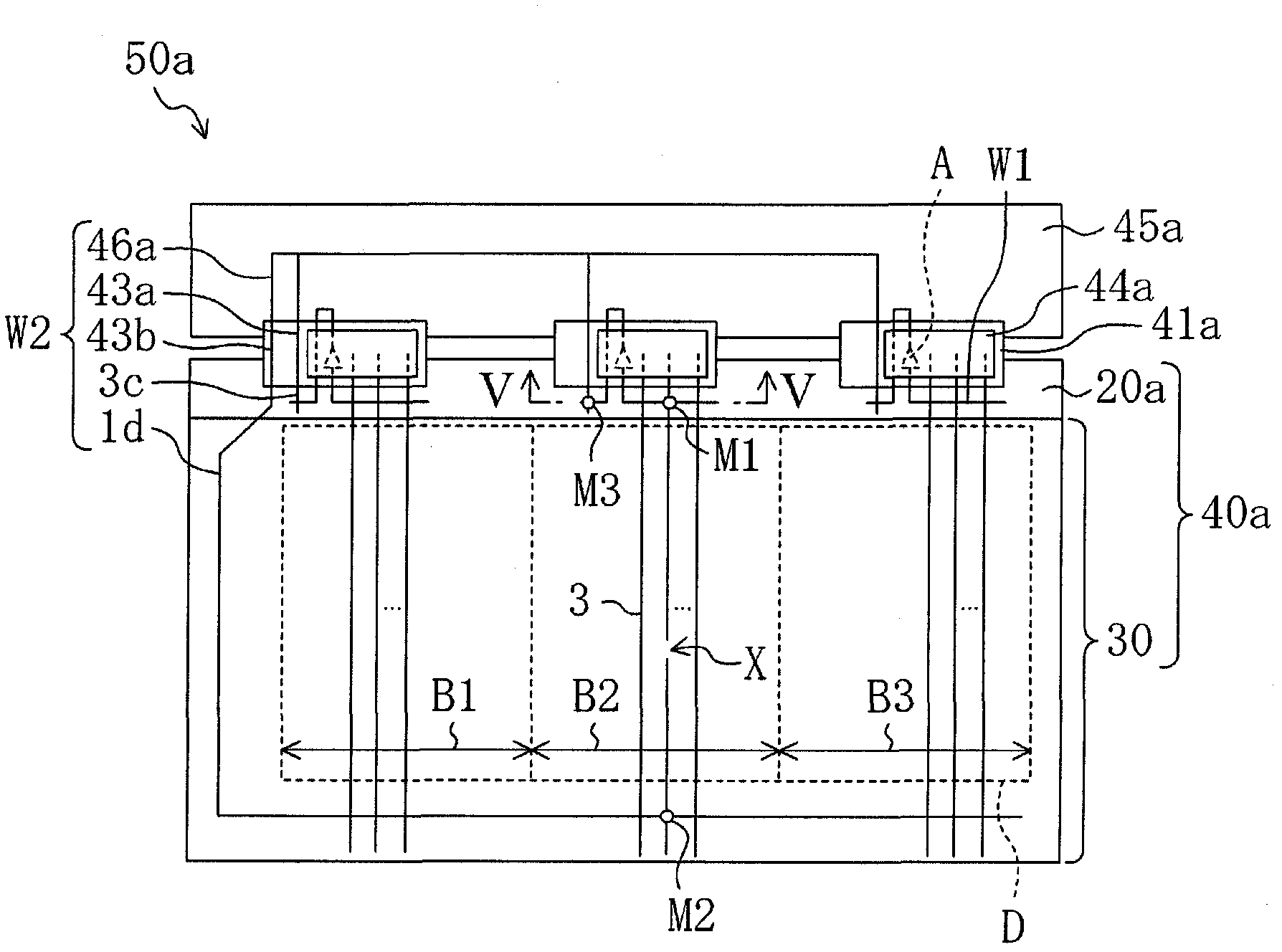

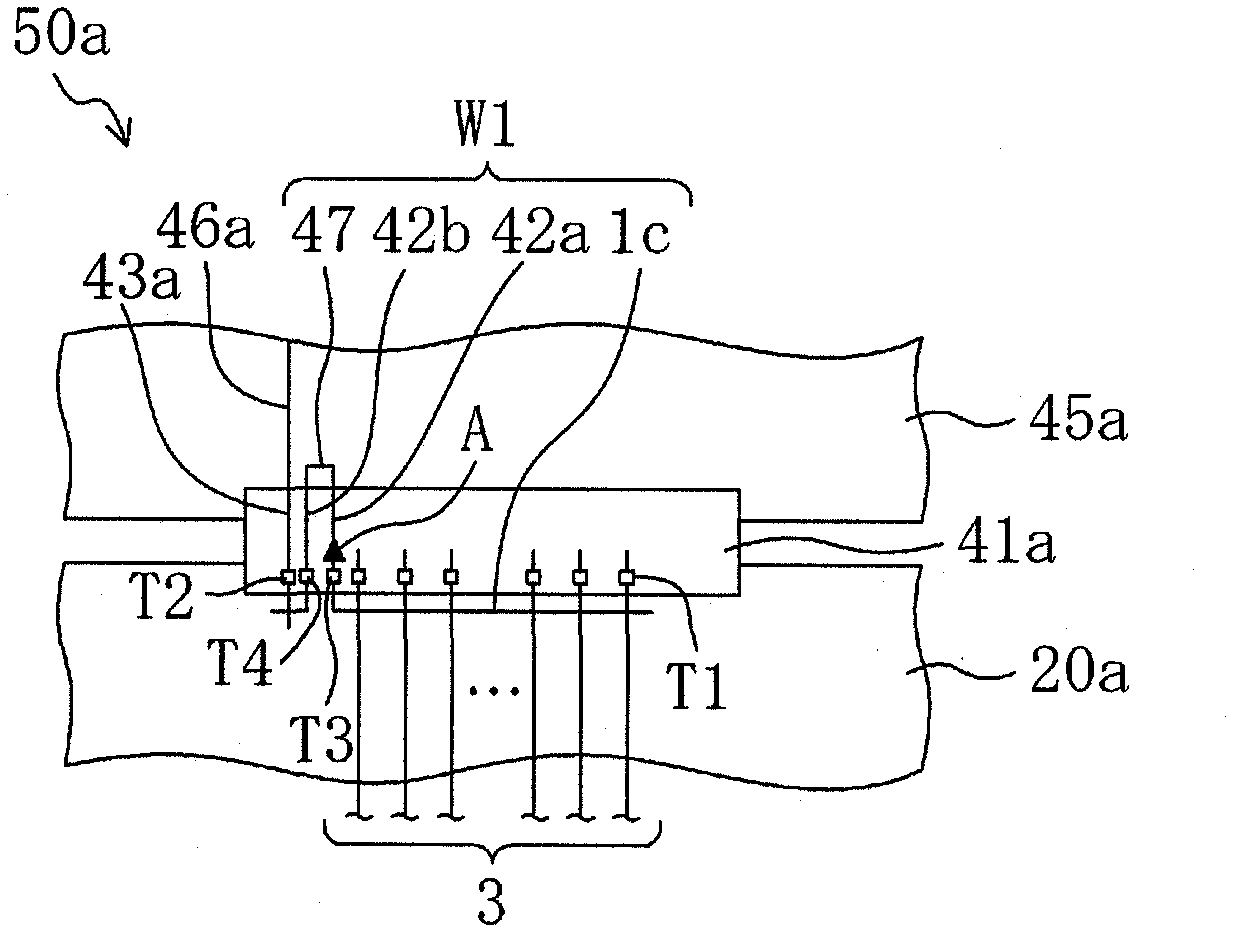

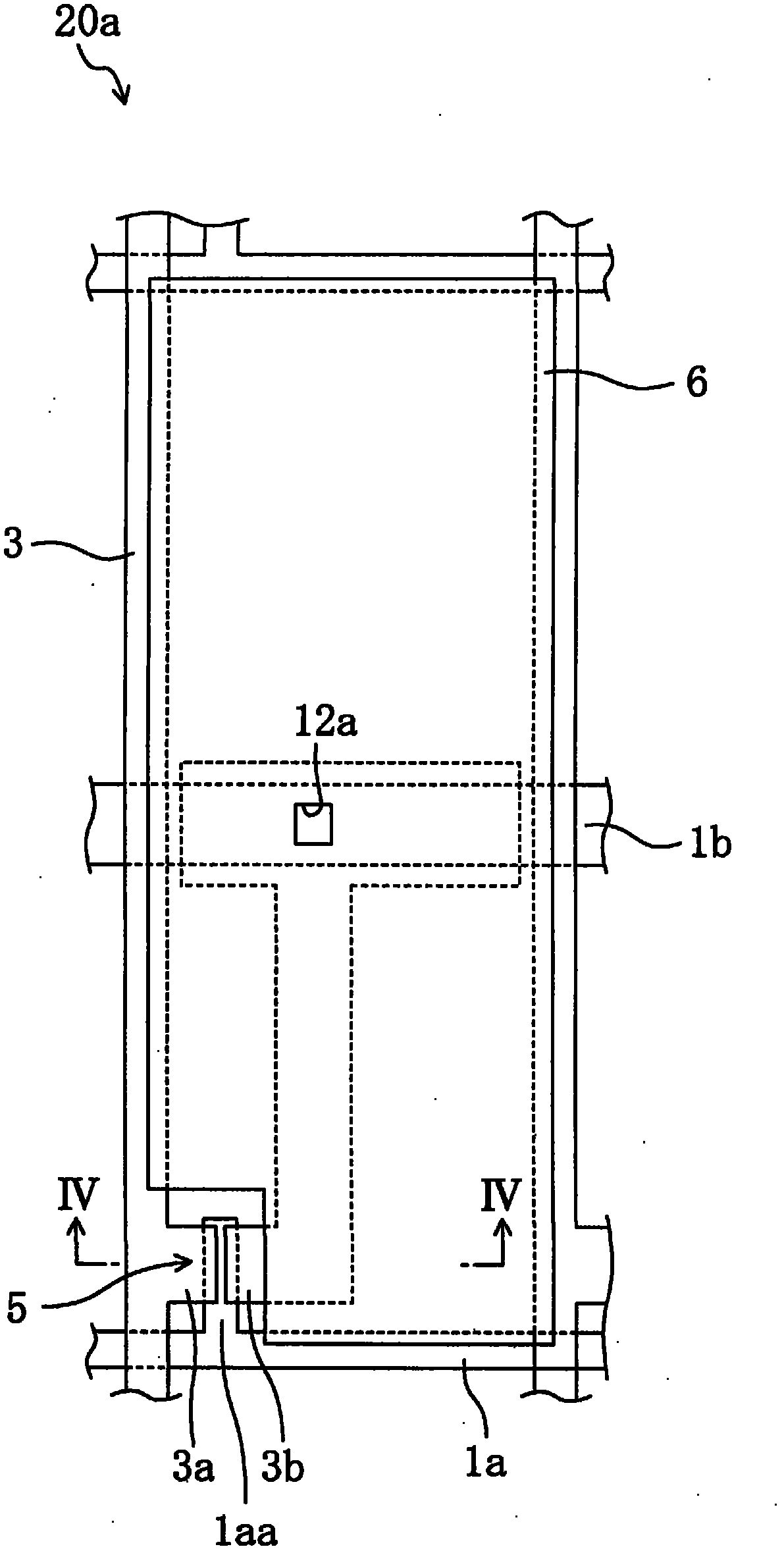

[0065] Figure 1 to Figure 5 Embodiment 1 of the display device, its manufacturing method, and active matrix substrate of the present invention is shown.

[0066] Specifically, figure 1 It is a plan view of the liquid crystal display device 50a of this embodiment, figure 2 It is an enlarged plan view of the film substrate 41a constituting the liquid crystal display device 50a and its surroundings. in addition, image 3 is a plan view showing one pixel of the active matrix substrate 20a constituting the liquid crystal display device 50a, Figure 4 is along image 3 The cross-sectional view of the active matrix substrate 20a and the liquid crystal display panel 40a equipped with it on the line IV-IV in FIG. and, Figure 5 is along figure 1 A cross-sectional view of the active matrix substrate 20a taken along line V-V in FIG.

[0067] Such as figure 1 As shown, the liquid crystal display device 50a includes: a liquid crystal display panel 40a; three film substrates 4...

Embodiment approach 2

[0123] Image 6 It is an enlarged plan view of the film substrate 41b constituting the liquid crystal display device 50b of this embodiment and its surroundings. In addition, in the following embodiments, for the Figure 1 to Figure 5 The same reference numerals are attached to the same parts, and detailed description thereof will be omitted.

[0124] In Embodiment 1 above, one first wiring W1 and one amplifier circuit A are provided for each film substrate 41a, but in this embodiment, as Image 6 As shown, two first wirings W1 and amplifier circuits A are provided for each film substrate 41b.

[0125] Specifically, as Image 6 As shown, in the active matrix substrate 20b (liquid crystal display panel 40b) constituting the liquid crystal display device 50b of this embodiment, the plurality of source lines 3 in the blocks B1 to B3 constitute two wiring groups G1 and G2. and, if Image 6 As shown, in the liquid crystal display device 50b, the first wiring W1 and the amplifi...

Embodiment approach 3

[0128] Figure 7 It is a plan view of the liquid crystal display device 50c of this embodiment.

[0129] In Embodiments 1 and 2 above, the source driver 44a is provided on the film substrates 41a and 41b, respectively, but in this embodiment, the source driver 35a is provided on the liquid crystal display panel 40c (active matrix substrate 20c).

[0130] Such as Figure 7 As shown, the liquid crystal display device 50c includes a liquid crystal display panel 40c and a film substrate 45c attached to the upper end of the liquid crystal display panel 40c in the figure via an ACF (not shown).

[0131] Such as Figure 7As shown, the liquid crystal display panel 40c includes an active matrix substrate 20c and a counter substrate 30 arranged to face each other.

[0132] In the active matrix substrate 20c, the structure of the display region D is substantially the same as that of the active matrix substrate 20a in Embodiment 1, as shown in Figure 7 As shown, on the outside of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com