Method and device for rapidly adjusting water yield and effluent pressure of hydraulic monitor of fire engine

A technology for fire trucks and water output, which is applied in transportation and packaging, vehicle parts, circuits or fluid pipelines, etc. It can solve the problems of difficult on-site command, slow fire extinguishing speed, and low efficiency, so as to improve the efficiency of fire fighting work and improve The effect of fire extinguishing speed and fire loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below through specific embodiments.

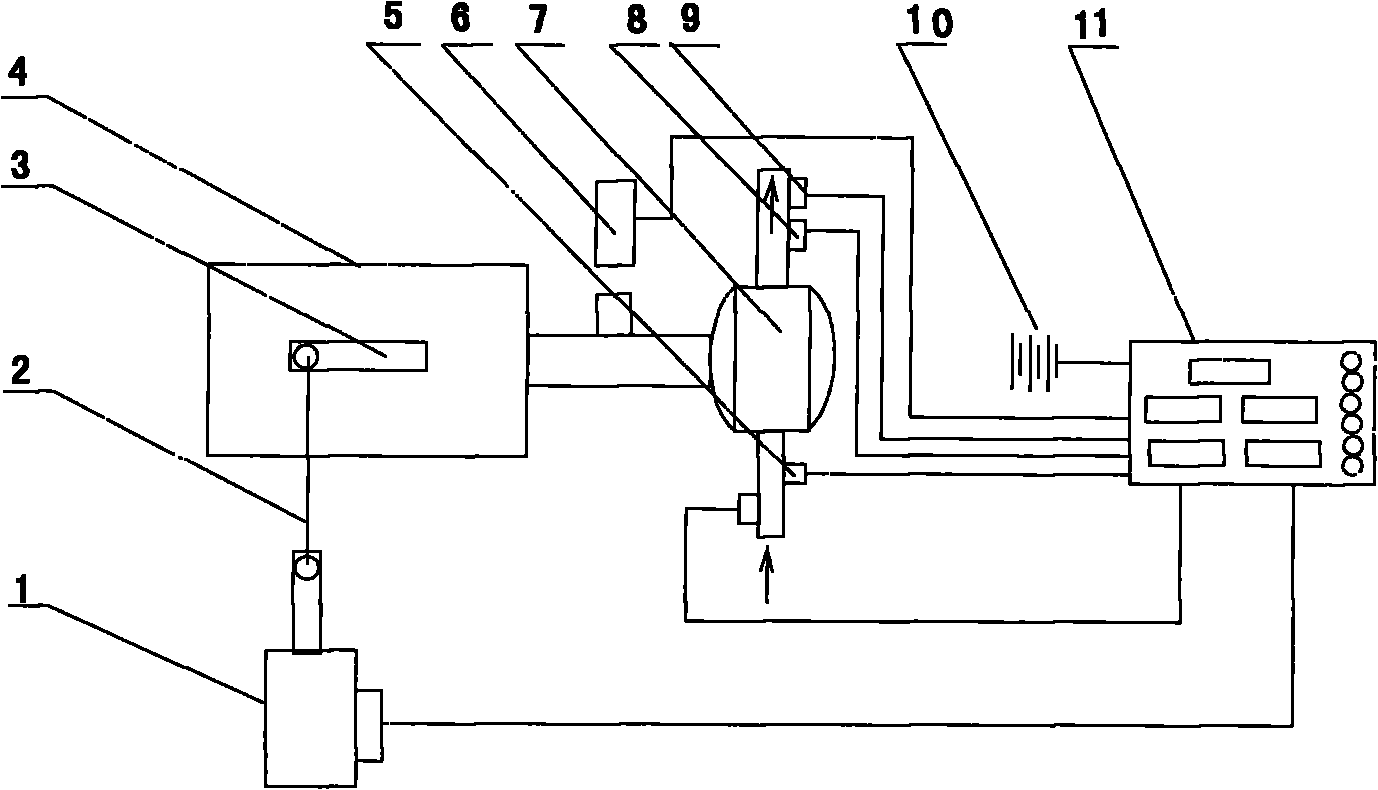

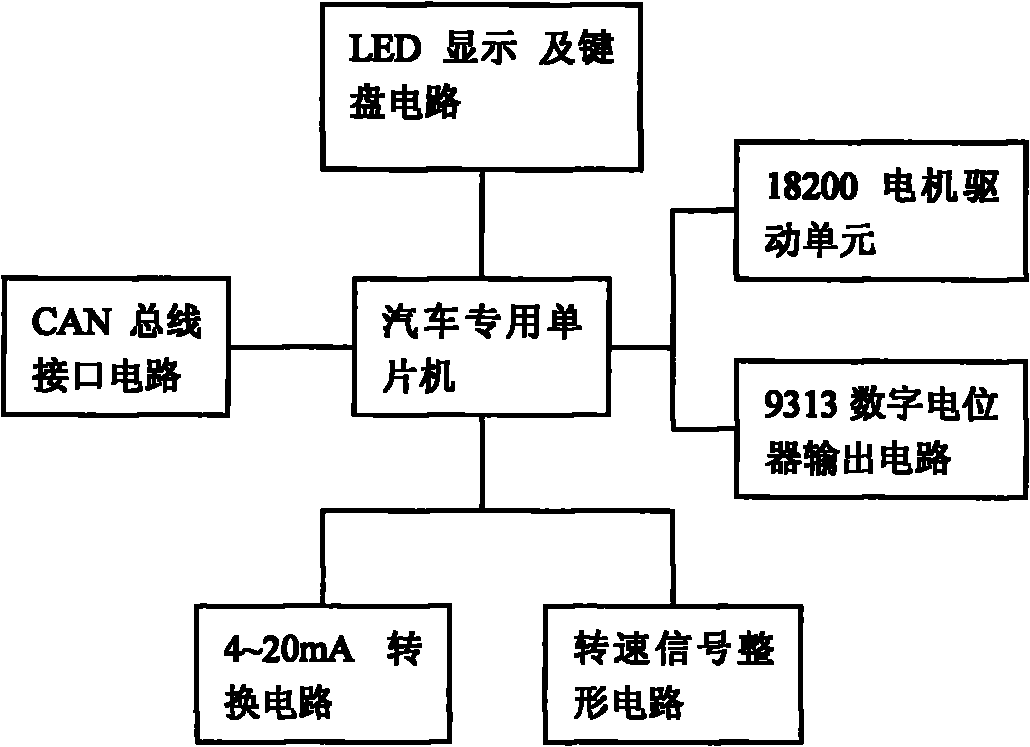

[0035] A device for quickly adjusting the water output and pressure of a fire engine water gun, which is composed of a motor 1, an accelerator 3, an engine 4, and a water pump 7. The water inlet pipe of the water pump 7 is provided with a water inlet pressure sensor 5; There is a water outlet pressure sensor 8 and an outlet water flow rate sensor 9; a speed sensor 6 is connected to the connecting shaft between the engine 4 and the water pump 7; connect. A pull rope 2 is connected between the motor 1 and the accelerator 3; the power supply 10 is connected with the controller 11.

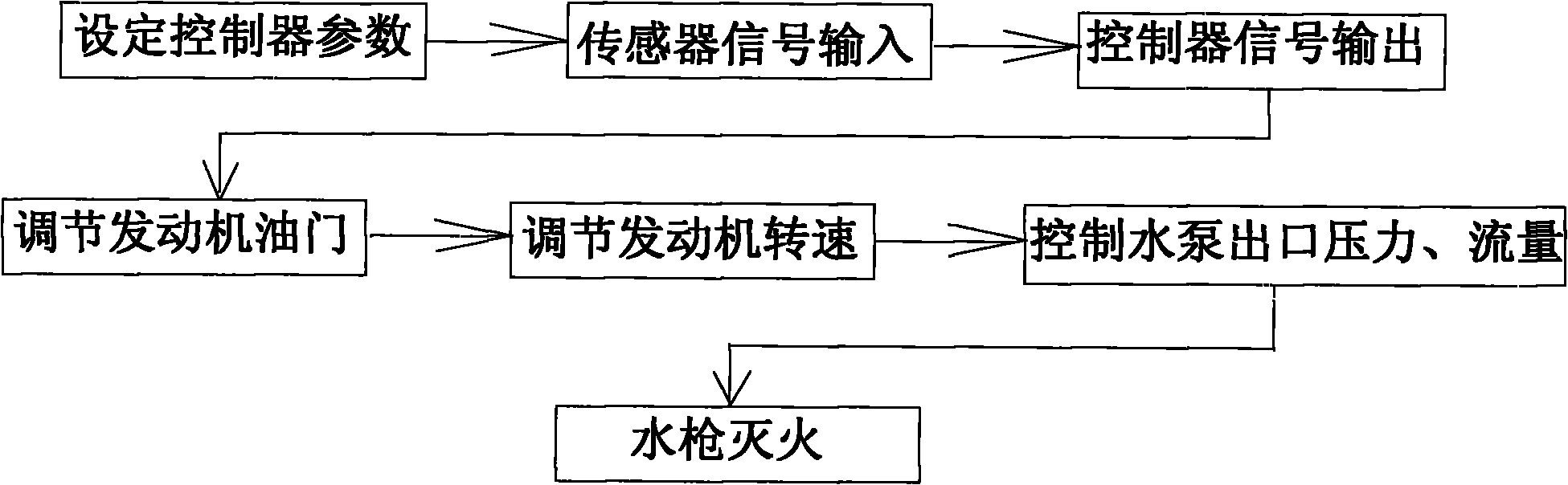

[0036] A method for quickly adjusting the water outlet volume and water outlet pressure of a fire truck water gun, comprising the following steps:

[0037] (1) Install the controller on the fire truck, and install the pressure sensor and flow rate sensor at the inlet and outlet of the fire pump; (2) Set the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com