Electric screw driver capable of detecting correct locking of screw

An electric screwdriver and locking technology, applied in screwdrivers, power tools, wrenches, etc., can solve the problems that the electric screwdriver cannot know the locking screw, the electric motor is useless, and the screw cannot be tightened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

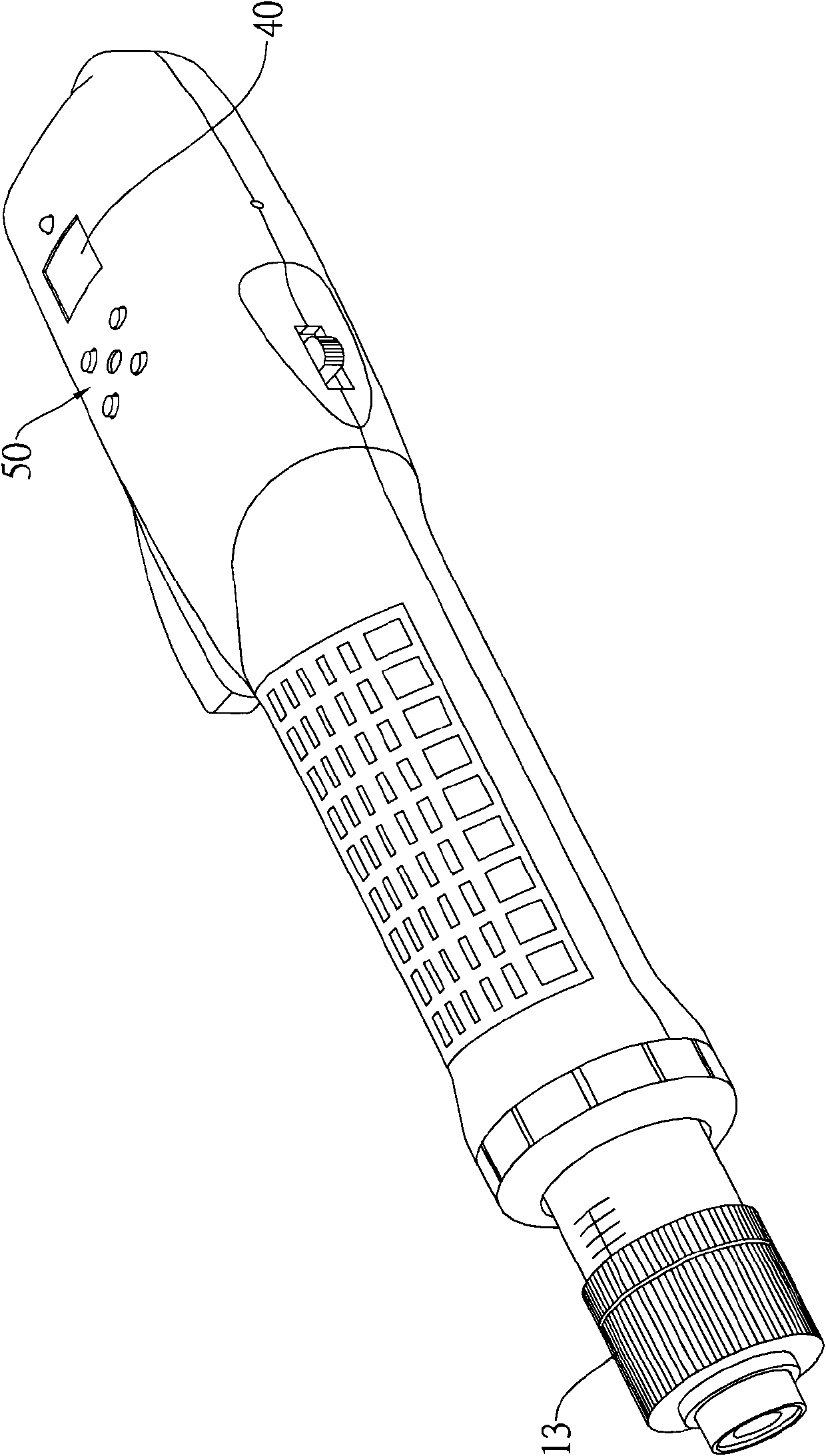

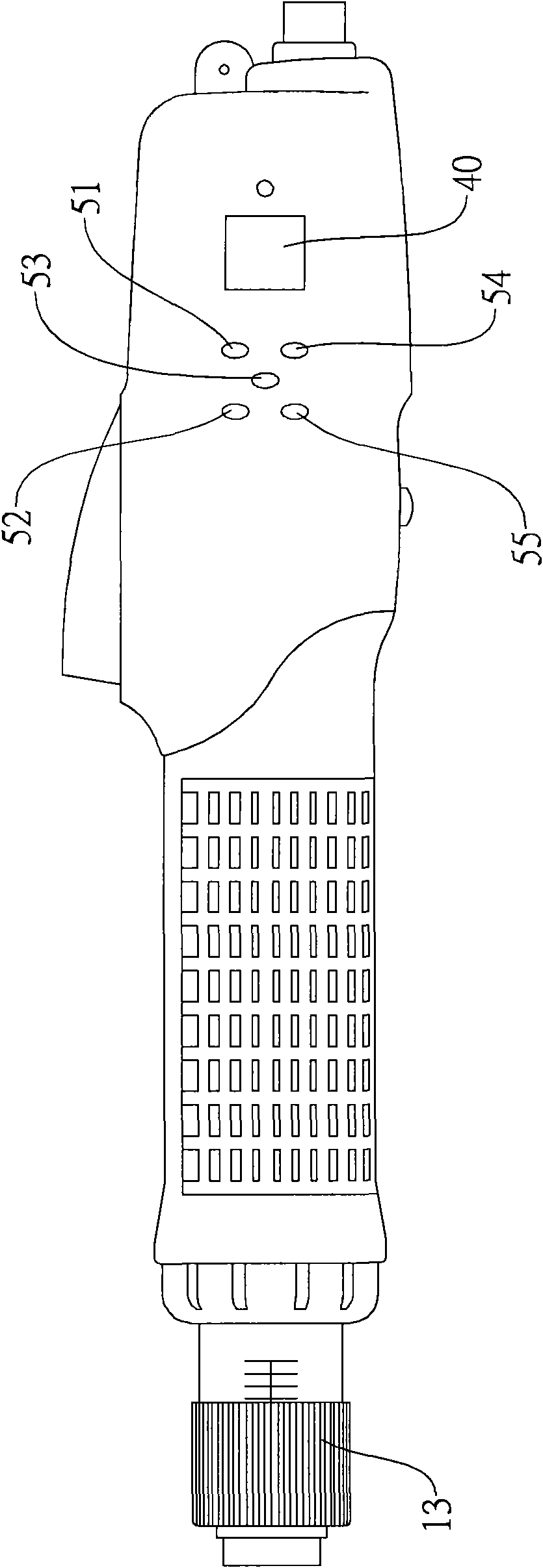

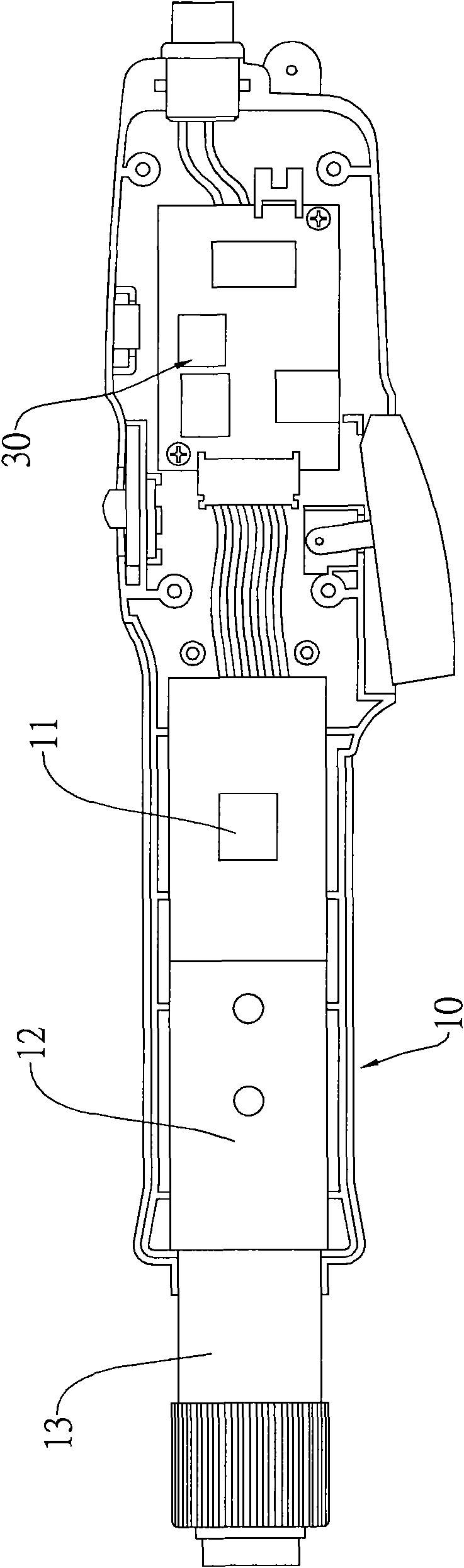

[0042] The electric screwdriver that can detect whether the screw is locked correctly in the present invention can be a manual electric screwdriver or an electric electric screwdriver, please refer to Figure 1 to Figure 4 As shown, a preferred embodiment of the present invention is an example of a hand-operated electric screwdriver, which includes a sub-drive module 10, a stop detection unit 20, a control unit 30, a display unit 40, an operation unit 50 and An alarm module 60 .

[0043] Such as image 3 As shown, the above-mentioned screwdriver drive module 10 includes an electric motor 11, a clutch unit 12 and a tool head 13, the clutch unit 12 is connected between the electric motor 11 and the tool head 13, and when the tool head 13 is detected to turn the screw (Not shown in the figure) When tightening, that is, the automatic switching makes the tool head 13 temporarily detached from the drive of the electric motor 11 .

[0044] Such as Figure 4 As shown, the stop dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com