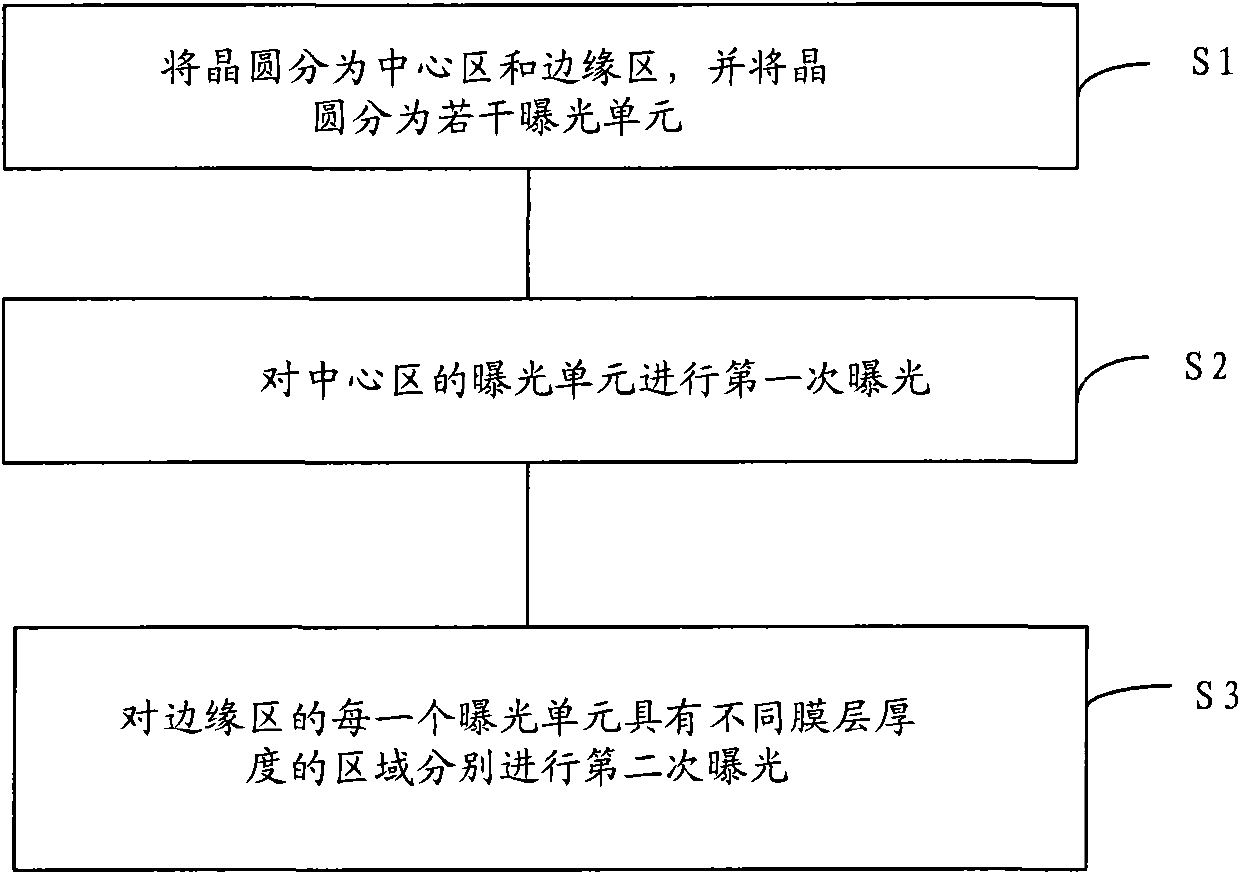

Wafer exposure method

An exposure method and wafer technology, which are applied in microlithography exposure equipment, photolithography process exposure devices, etc., can solve problems such as poor exposure, and achieve the effect of avoiding poor exposure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

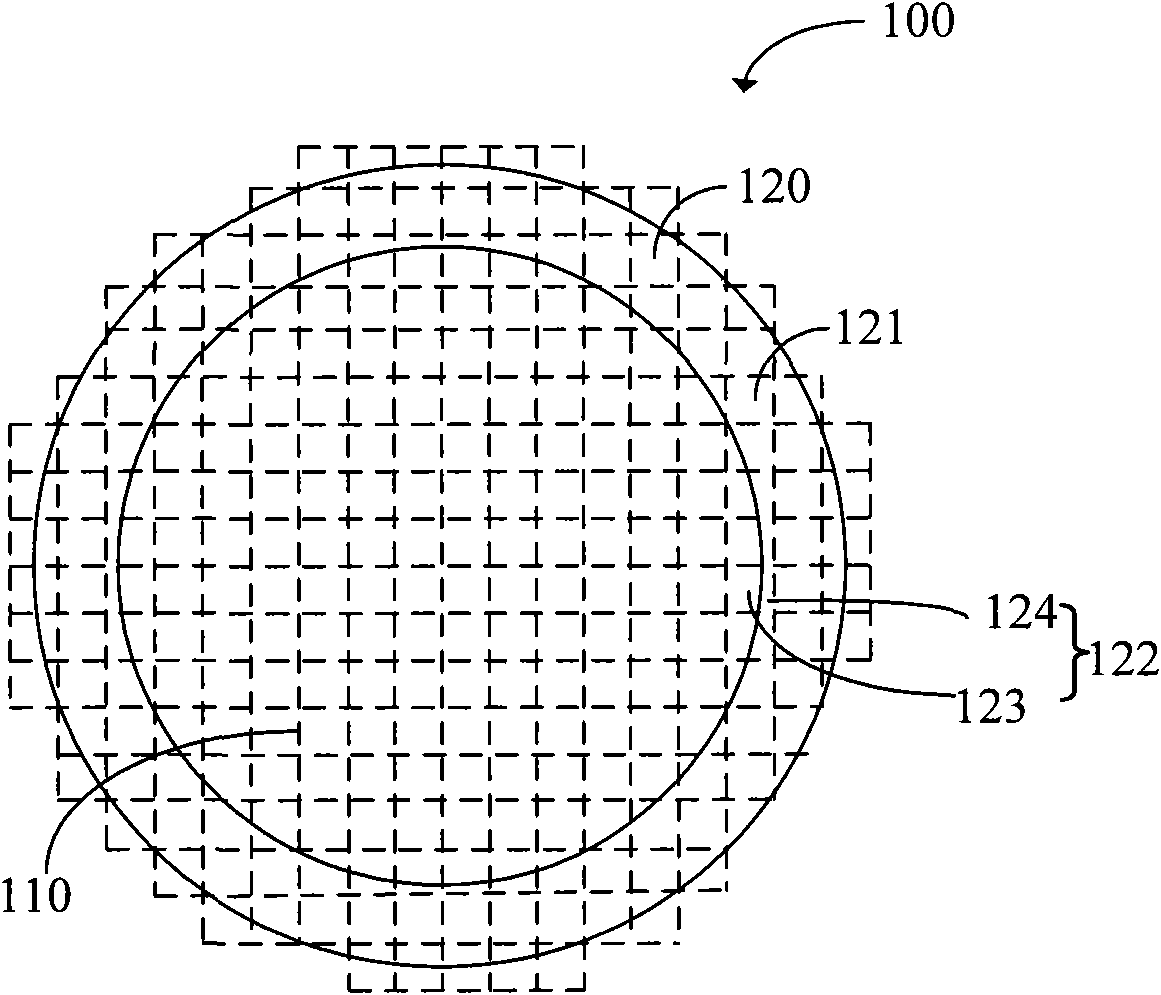

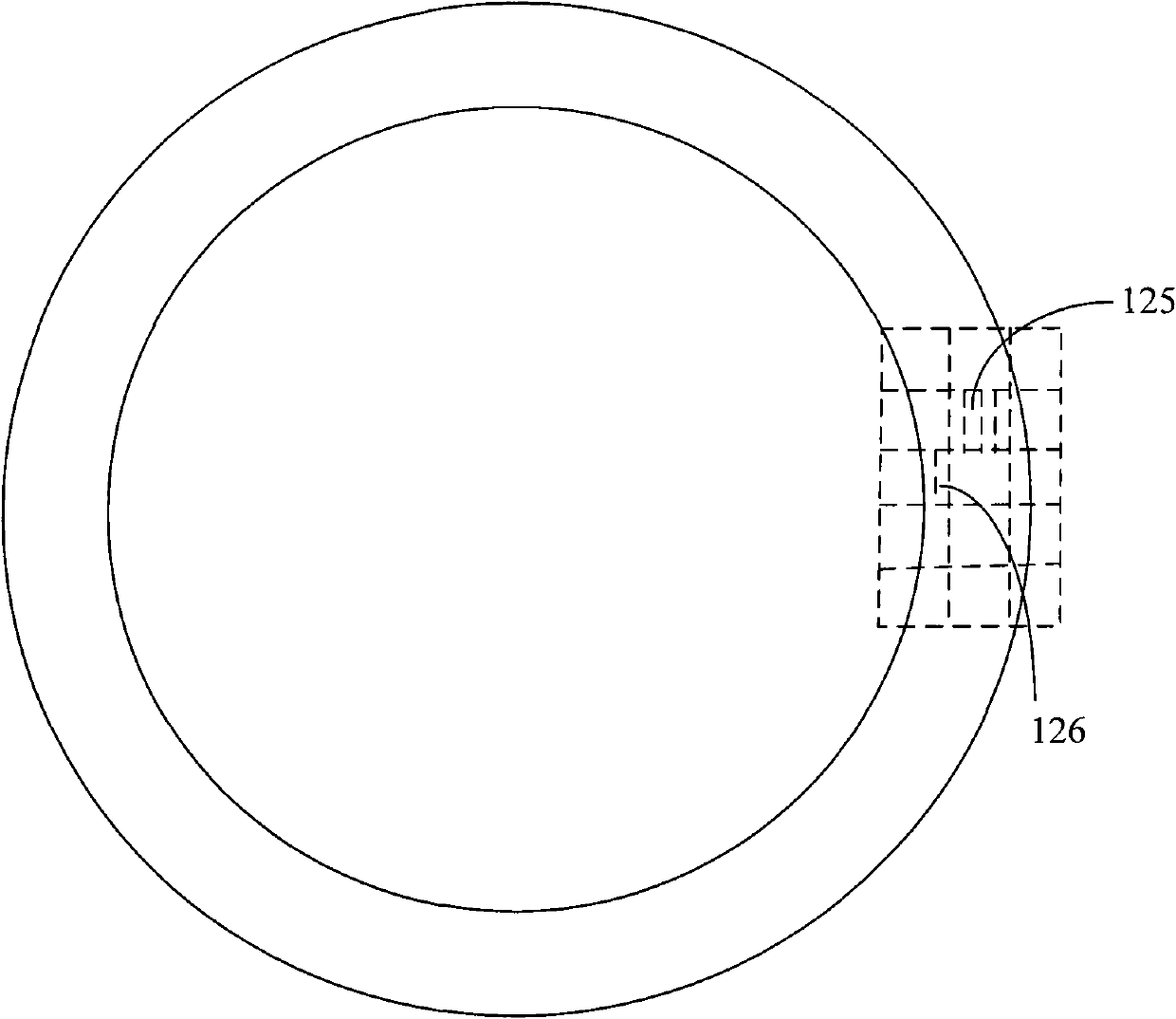

[0025] In the semiconductor exposure process, the exposure process is usually performed by forming a photoresist layer on a wafer with several layers of film layers. In fact, each film layer is not evenly distributed on the entire wafer surface. Generally, near the center of the wafer The film layers in the area of the wafer are evenly distributed and the surface is flat. Therefore, when exposing the exposure unit in the central area of the wafer, there will be no problem of poor exposure in some areas due to poor focus; however, the film layers in the edge area of the wafer are not exposed. Evenly distributed, the surface is not flat, so when exposing the exposure units in the edge area of the wafer, some exposure units will deviate from the focal plane and cause poor exposure (such as underexposure), especially in semiconductor manufacturing with feature sizes smaller than 0.18 μm , due to the narrowing of the process window due to the narrowing of the line width, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com