Concentrated winding type driving motor for vehicle

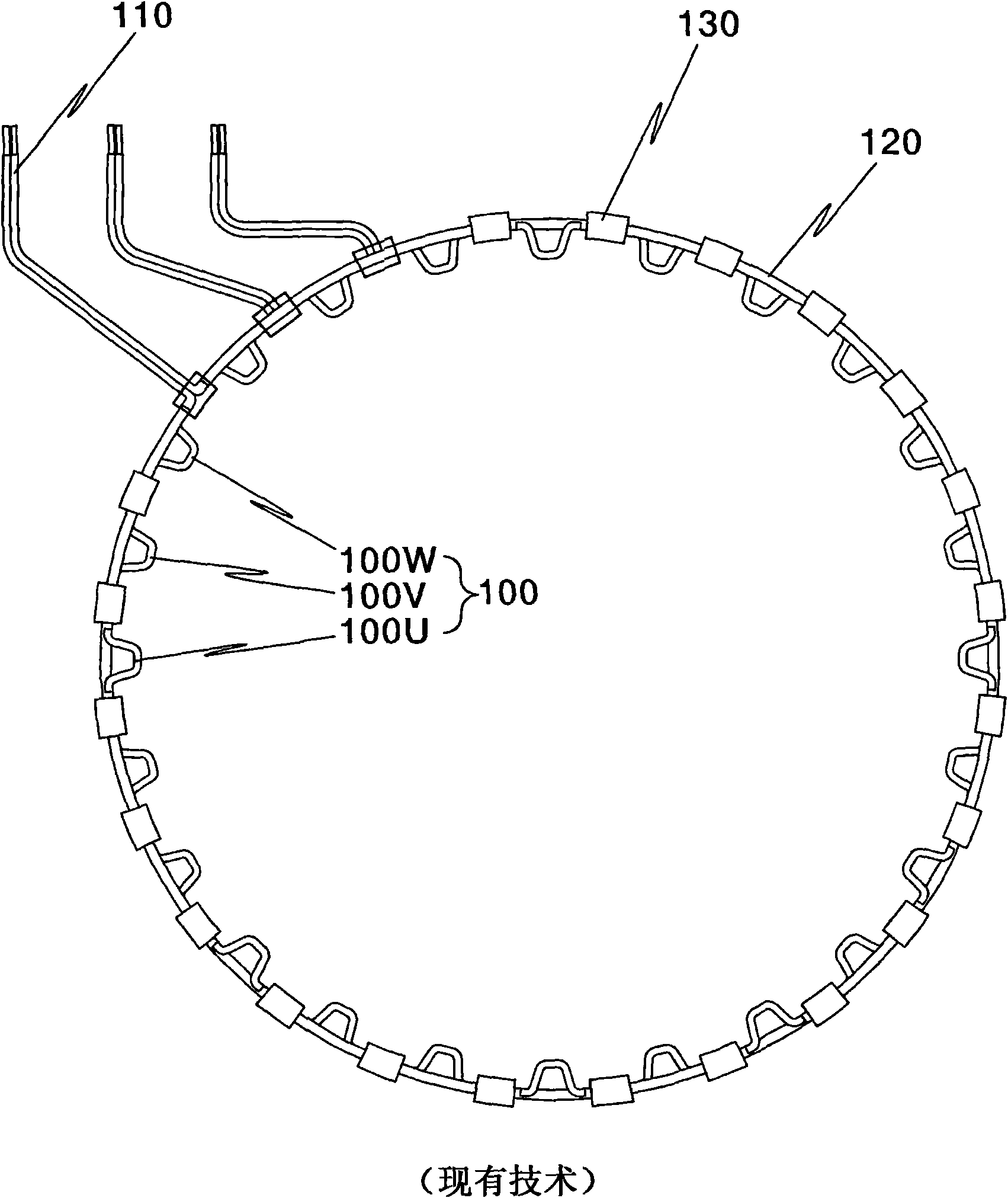

A technology that concentrates windings and drives motors. It is applied in the manufacture of motor generators, windings, and electromechanical devices. It can solve problems such as difficulty in achieving optimal vibration and temperature conditions, limited space, and difficulty in achieving stable connections. It achieves strong connection strength. , Improve weldability, improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

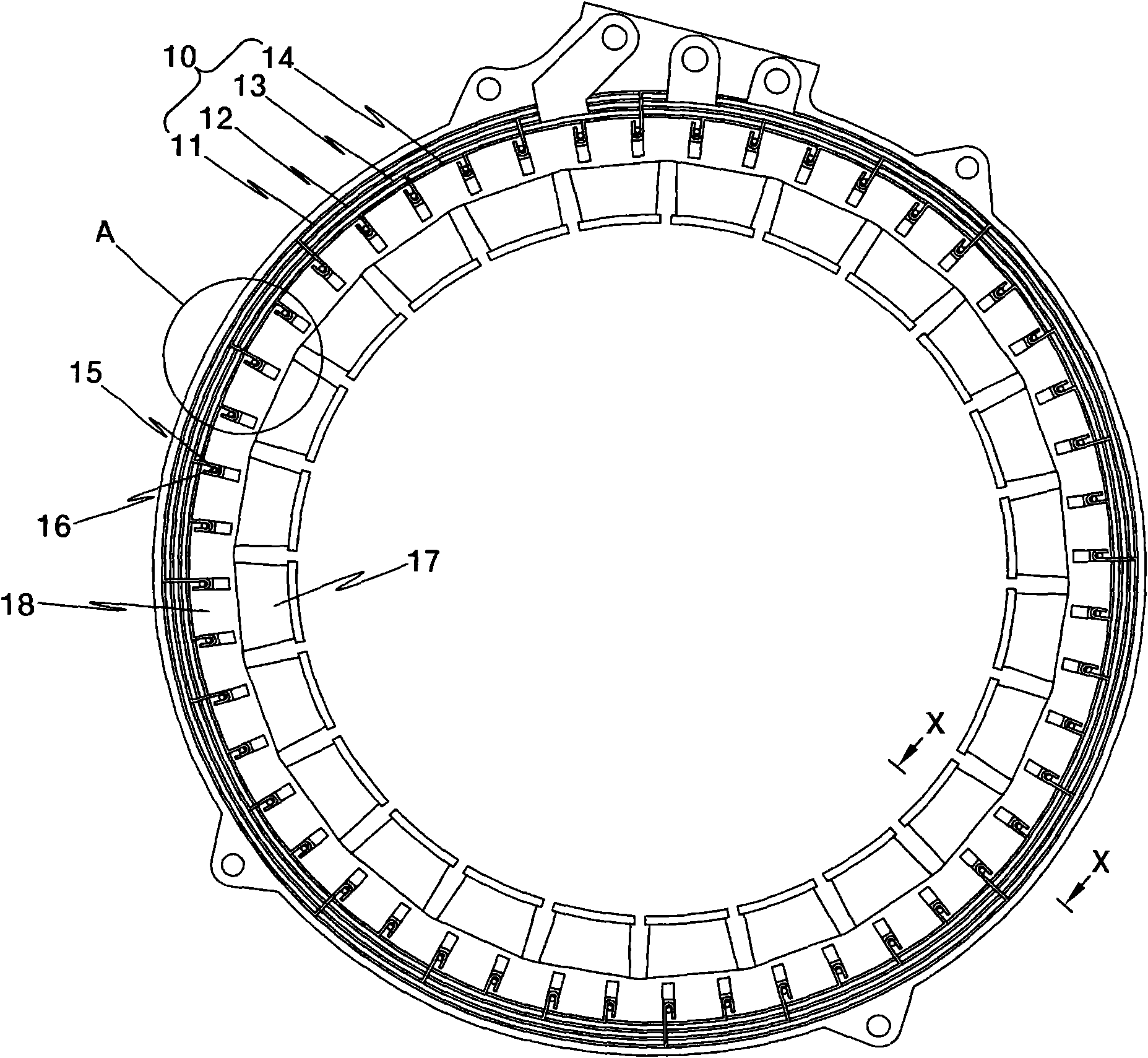

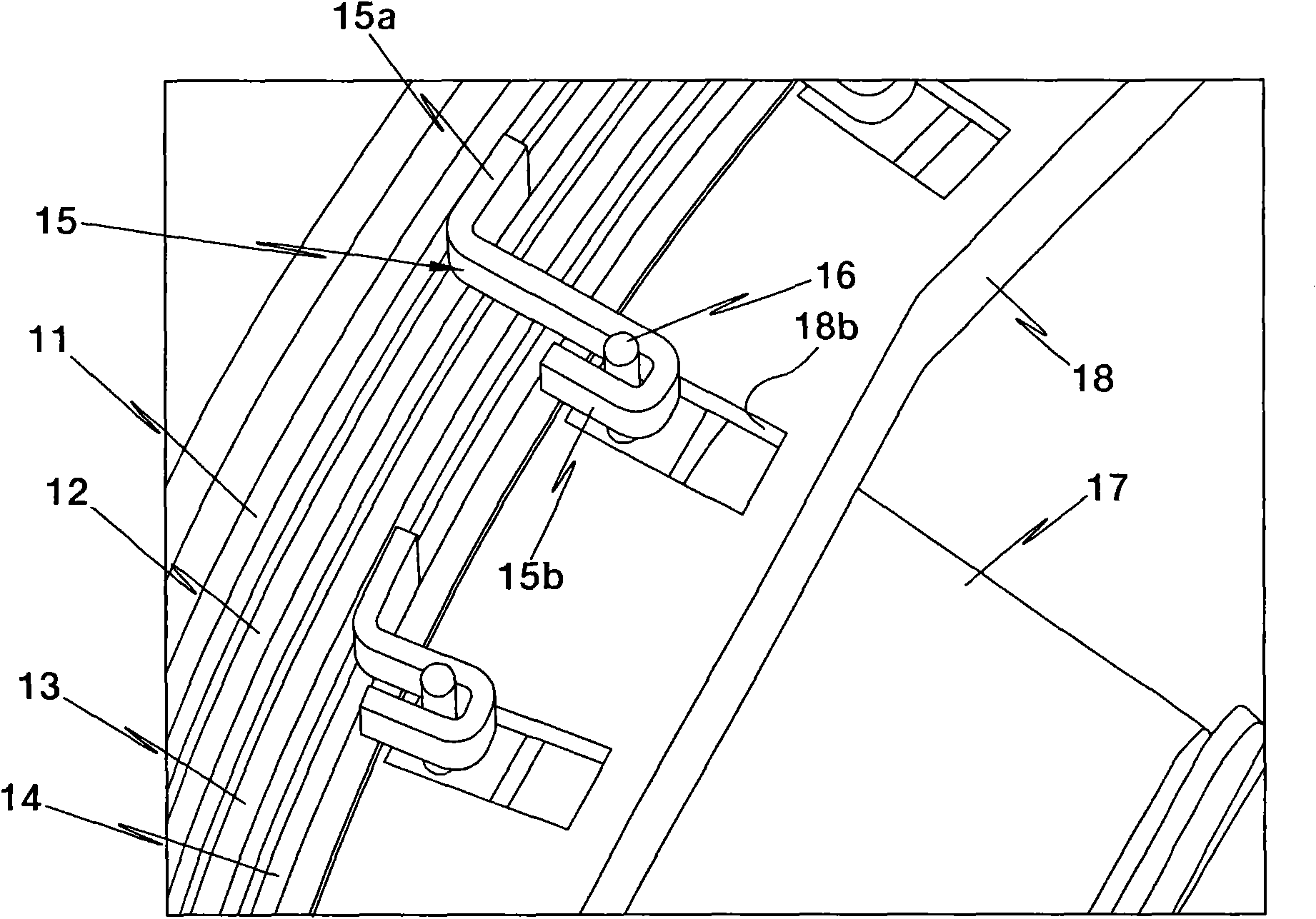

[0025] In a first aspect, the present invention is characterized by a concentrated winding type drive motor for a vehicle, including a conductor holder provided with a plurality of receiving slots concentrically formed at predetermined intervals and provided with through holes at predetermined intervals, each of which is inserted And fixed to a plurality of conductive plates in each receiving slot, a plurality of coils each vertically passing through the through hole, and each arranged in the radial direction of the conductor holder to connect one of the conductive plates with one of the coils A plurality of connecting pieces, wherein one end of each connecting piece is bent in the circumferential direction of the conductor holder and extends down to contact with one of the conductive plates, and the other end of each connecting piece is bent to form a curve A slot, a part of the circumferential surface of one of the coils is surrounded by the curved slot.

[0026] Reference will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com