Pouring channel capable of preventing sand drop

A channel and anti-dropping technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve problems such as sand inclusions in castings, product quality problems, and lower casting quality, so as to avoid sand inclusions, prevent sand dropping, and improve quality Effect

Inactive Publication Date: 2011-06-15

SUFA HENGDIAN MACHINERY CNNC

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The pouring channel is an important part of introducing molten metal into castings, and the unreasonable design of the pouring channel will lead to serious product quality problems

The existing pouring channel includes a sprue and a runner, the two are directly connected, and the molten metal rushes in from the top of the sprue, forming a large impact force at the bottom of the sprue, where it is also very easy to wash sand, resulting in castings Defects such as sand inclusions reduce the quality of castings

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

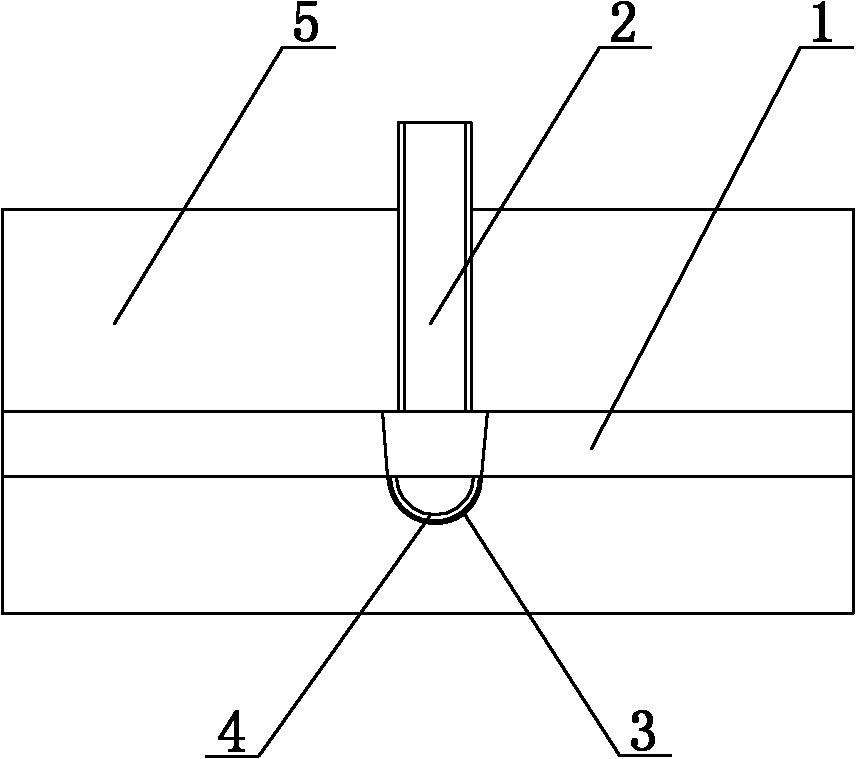

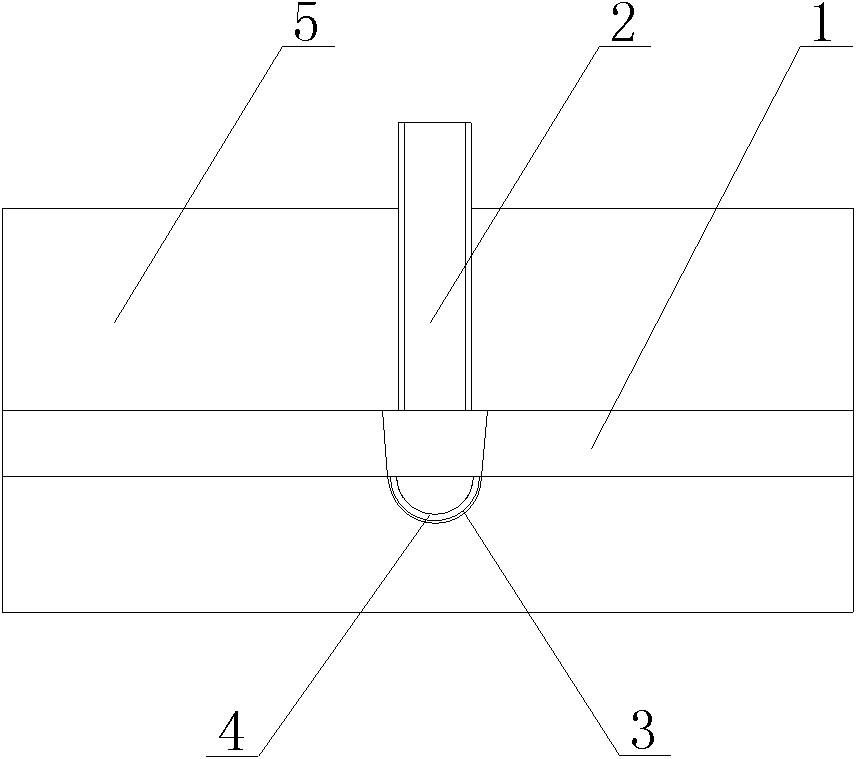

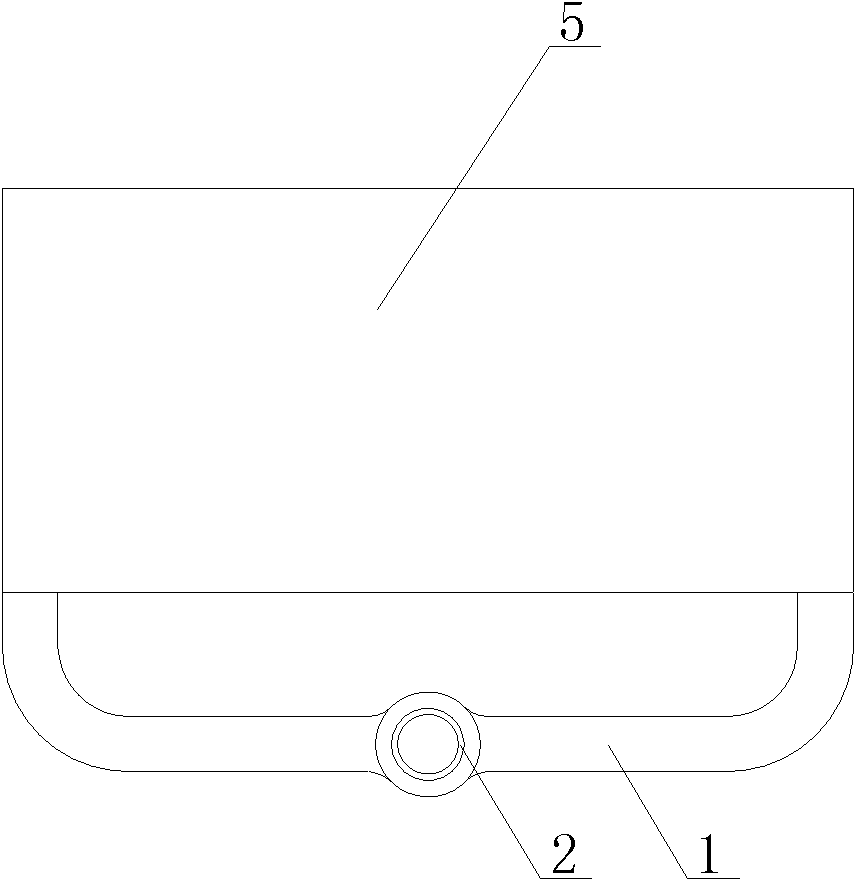

The invention provides a pouring channel capable of preventing sand drop, comprising a runner connected with a casting chamber, and a sprue connected with the runner; wherein the bottom of the sprue is provided with an arc platform, and a pouring gate bowl is arranged on the arc platform. Molten metal rushes into the pouring gate bowl at the bottom of the sprue from the top of the sprue, so that sand drop is prevented, the sand is prevented from being contained in the casting, and quality of the casting is improved.

Description

An anti-sand pouring channel technical field The invention relates to the field of casting, in particular to a pouring channel for preventing sand loss. Background technique The pouring channel is an important part of introducing molten metal into castings, and the unreasonable design of the pouring channel will lead to serious product quality problems. The existing pouring channel includes a sprue and a runner, the two are directly connected, and the molten metal rushes in from the top of the sprue, forming a large impact force at the bottom of the sprue, where it is also very easy to wash sand, resulting in castings Defects such as sand inclusions reduce the quality of castings. Contents of the invention The technical problem to be solved by the present invention is to provide a pouring channel for preventing sand loss, which can prevent sand loss, avoid sand inclusion in castings, and improve the quality of castings. In order to solve the above-mentioned existing ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22C9/08

Inventor 于忠良朱维祥

Owner SUFA HENGDIAN MACHINERY CNNC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com