Method for producing brake disc from resin sand

A technology of resin sand and brake discs, which is applied to casting molding equipment, molds, cores, etc., can solve the problems of rough surface finish of castings, inability to quickly demould, low dimensional accuracy, etc., to improve dimensional accuracy and surface finish, The negative number of parting is small and the sand mold strength is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

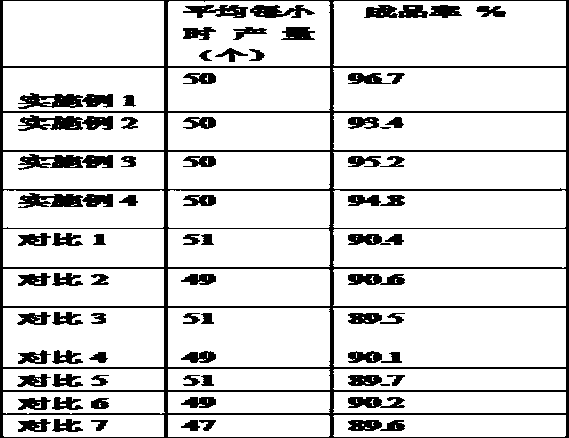

Examples

Embodiment 1

[0039] 1) Preparation of resin sand: Add PZ~Ⅲ to PZ~Ⅰ according to 1.8% of the mass of PZ~Ⅰ and stir for 30s to obtain a mixed resin, which is added to a one-component resin tank; PZ~II is added to a two-component resin tank middle; the natural quartz stone is pneumatically transported to the sand storage tank above the continuous sand mixer; the natural quartz stone, mixed resin and PZ~Ⅱ are added to the continuous sand mixer according to the mass ratio of 98.9:0.6:0.5, and the sand mixing time is 10s, get resin sand;

[0040] 2) Modeling: Put the resin sand into the sand box until it is full, and scrape the flat sand in the sand box;

[0041] 3) Mold removal: transport the molded sand box to the mold removal station through the rails, and the mold removal time is 6 minutes;

[0042] 4) Core setting: After the mold is lifted from the sand box, it is transported to the core setting area by the single-line roller table for core setting, and the core setting time is 6 minutes; ...

Embodiment 2

[0047] 1) Preparation of resin sand: Add PZ~Ⅲ to PZ~Ⅰ according to 1.8% of the mass of PZ~Ⅰ and stir for 30s to obtain a mixed resin, which is added to a one-component resin tank; PZ~II is added to a two-component resin tank middle; the natural quartz stone is pneumatically transported to the sand storage tank above the continuous sand mixer; the natural quartz stone, mixed resin and PZ~Ⅱ are added to the continuous sand mixer according to the mass ratio of 98.8:0.7:0.5, and the sand mixing time is 10s, get resin sand;

[0048] 2) Modeling: Put the resin sand into the sand box until it is full, and scrape the flat sand in the sand box;

[0049] 3) Mold removal: transport the molded sand box to the mold removal station through the rails, and the mold removal time is 6 minutes;

[0050] 4) Core setting: After the mold is lifted from the sand box, it is transported to the core setting area by the single-line roller table for core setting, and the core setting time is 6 minutes; ...

Embodiment 3

[0055] 1) Preparation of resin sand: Add PZ~Ⅲ to PZ~Ⅰ according to 1.8% of the mass of PZ~Ⅰ and stir for 30s to obtain a mixed resin, which is added to a one-component resin tank; PZ~II is added to a two-component resin tank middle; the natural quartz stone is pneumatically transported to the sand storage tank above the continuous sand mixer; the natural quartz stone, mixed resin and PZ~Ⅱ are added to the continuous sand mixer according to the mass ratio of 99:0.6:0.4, and the sand mixing time is 10s, get resin sand;

[0056] 2) Modeling: Put the resin sand into the sand box until it is full, and scrape the flat sand in the sand box;

[0057] 3) Mold removal: transport the molded sand box to the mold removal station through the rails, and the mold removal time is 6 minutes;

[0058] 4) Core setting: After the mold is lifted from the sand box, it is transported to the core setting area by the single-line roller table for core setting, and the core setting time is 6 minutes;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com