Casting mold and mold assembling method

A casting mold and box cone technology, applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of sand rubbing, core head easily rubbing sand, core head rubbing sand, etc. Sand problem, the effect of solving the problem of easy sand rubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described below with reference to the drawings.

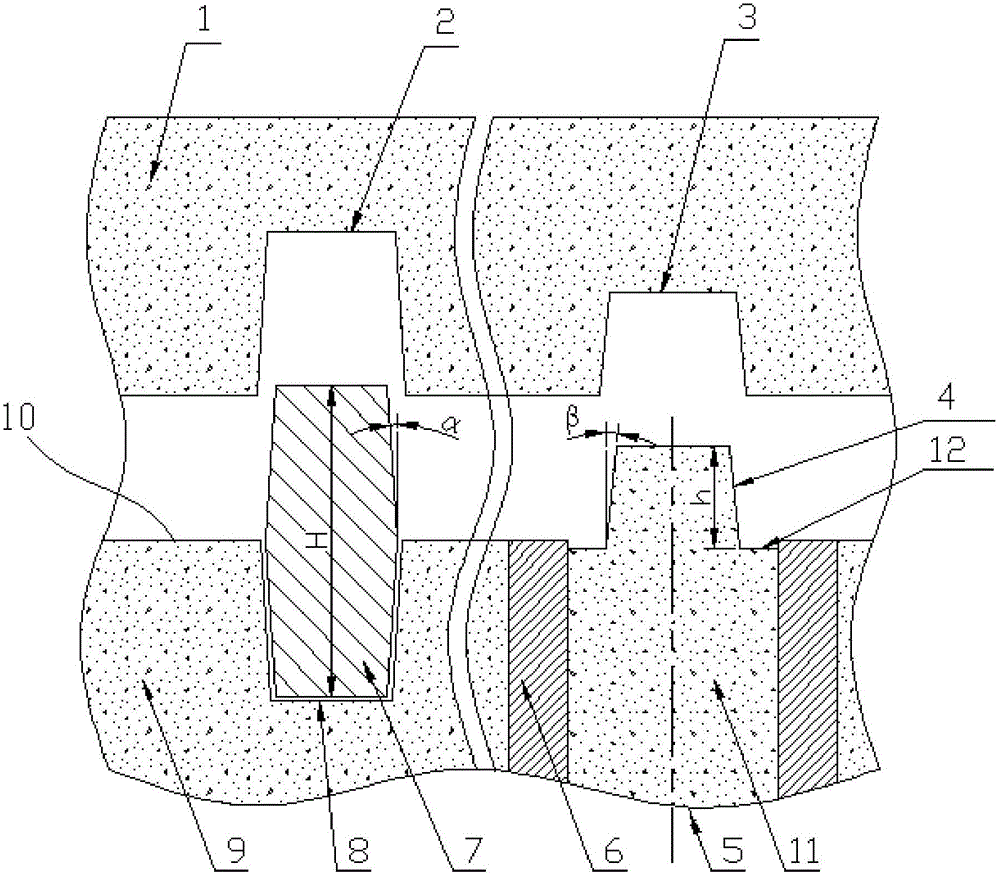

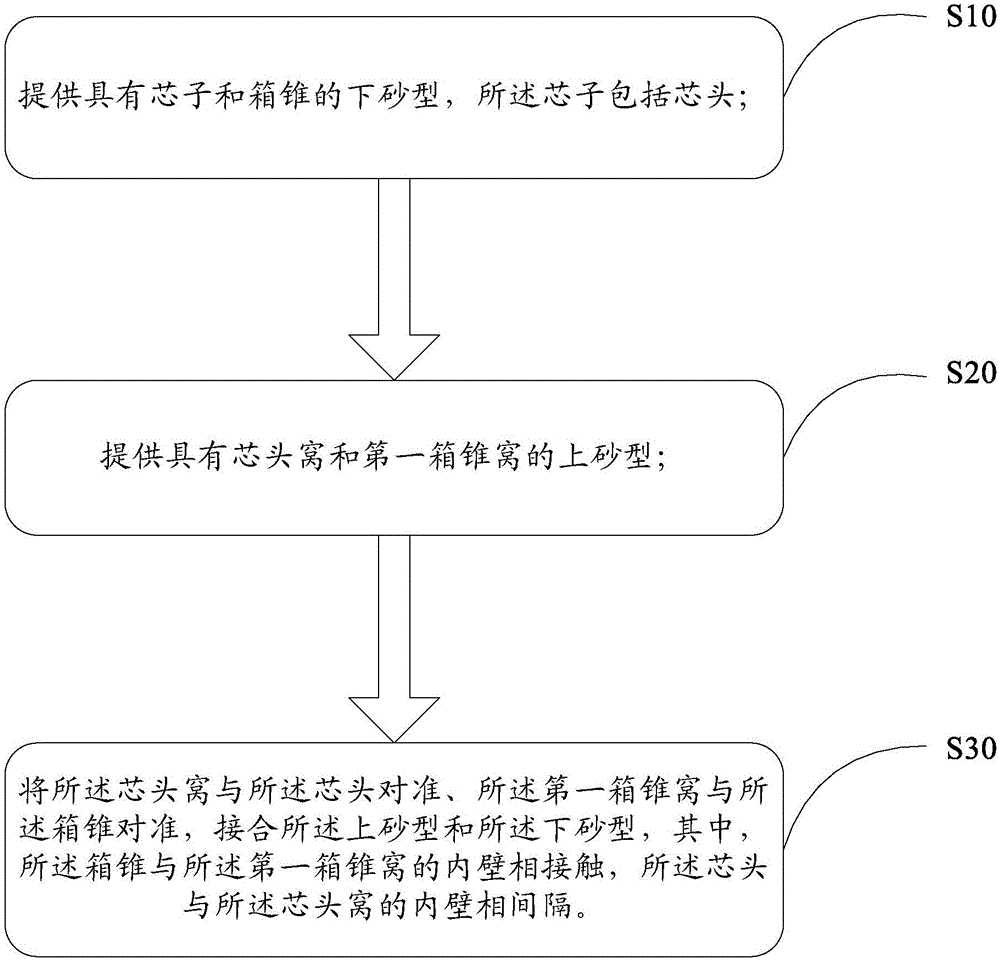

[0022] refer to figure 1 , the foundry mold of the present invention, comprising: comprising a lower sand mold 9 and an upper sand mold 1 joined to the lower sand mold 9; a core 5 arranged in the lower sand mold 9, and the core 5 is contained in a core socket 3 of the upper sand mold 1 The core head 4; also includes the box cone 7 arranged between the lower sand mold 9 and the upper sand mold 1, the upper sand mold 1 includes the first box cone socket 2 that accommodates the box cone 7, and the inner wall of the box cone 7 and the first box cone socket 2 In contact with each other, the core head 4 is spaced from the inner wall of the core head socket 3 . Since the box cone 7 is always in contact with the first box cone socket 2 during the box closing process, the core head 4 is spaced from the core head socket 3, thereby avoiding friction and sand loss between the core head socke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com