Pneumatic tire with rubber component containing epoxidized palm oil

A technology of pneumatic tires and palm oil, applied to special tires, tire parts, wheels, etc., can solve problems such as loss of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

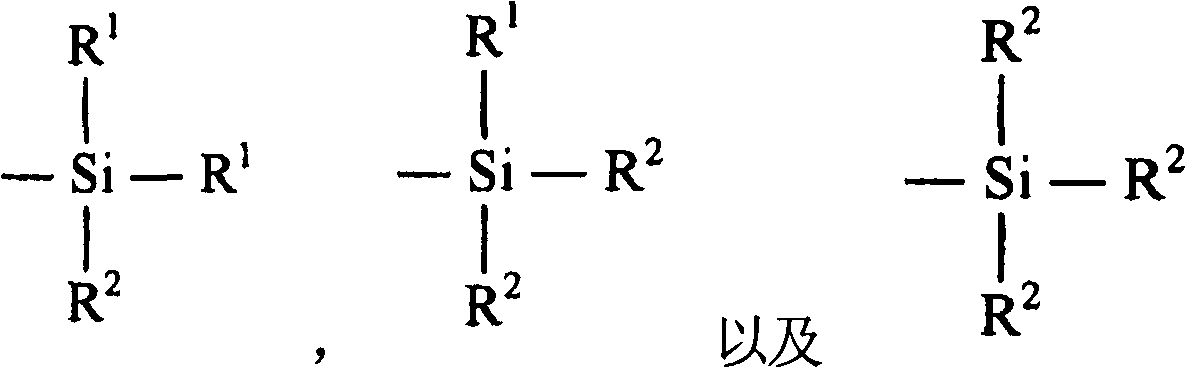

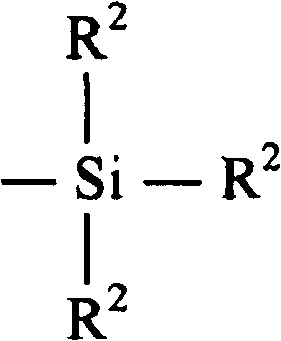

Method used

Image

Examples

Embodiment 1

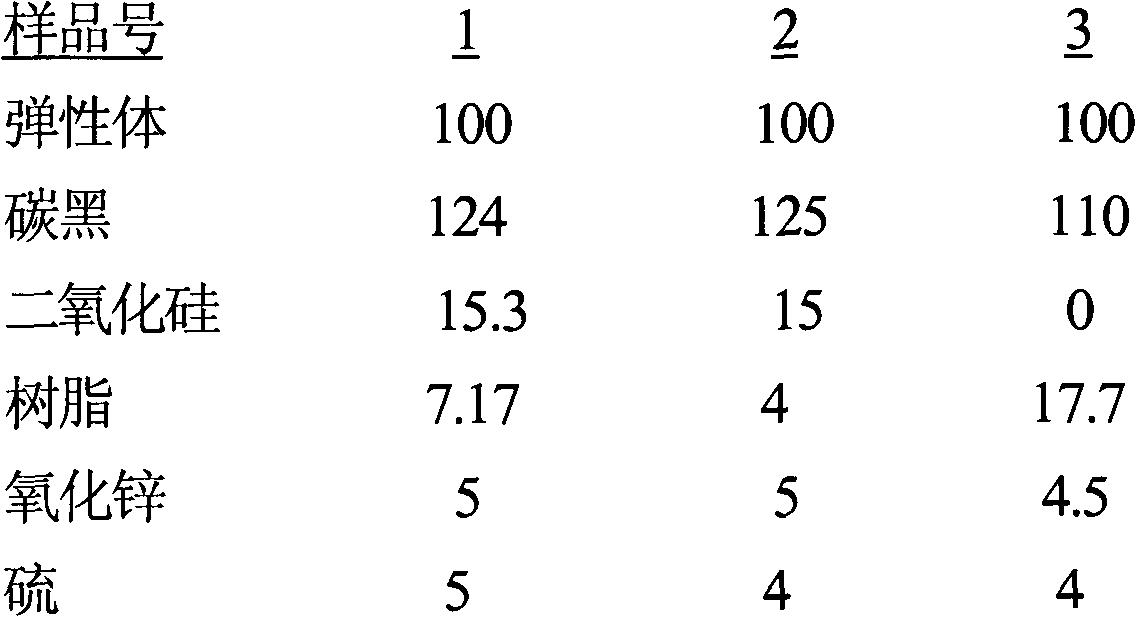

[0055] In this example, a rubber composition including epoxidized palm oil will be described. The rubber compound is prepared by multiple mixing steps. The formulation of this mixture is shown in Table 1, where all amounts are in phr. The physical properties of the samples were tested, and the results are shown in Table 2.

[0056] SBAT corresponds to ASTM D1871 Method 1.

[0057] A Flexsys MV2000 was used to measure Mooney viscosity (ML.sub.1+4 (100°C)) and Mooney scorch (t+5, T+20).

[0058] The viscoelastic properties Tan Delta and G' were measured using an Alpha Technologies Rubber Processing Analyzer (RPA). A description of the RPA 2000 and its capabilities, sample preparation, tests and subtests can be found in the literature listed below. H A Pawlowski and J S Dick, Rubber World, June 1992; J S Dick and H A Pawlowski, Rubber World, January 1997; and J S Dick and J A Pawlowski, Rubber & Plastics News, Apr. 26 and May 10, 1993.

[0059] Table 1

[0060]

[0061] ...

Embodiment 2

[0066] In this example, the tack retention of a tire component prepared with a rubber composition including epoxidized palm oil will be illustrated. The "tackiness" or tackiness of a rubber component is relative to the adhesion and bond retention of the component to other tire components during the tire manufacturing process. Some tire components, including beads, apexes, and sidewall covers are typically prepared prior to tire manufacture and may be stored for several weeks prior to use.

[0067] Beads made using the mixture described in Example 1 were stored for up to 3 months and evaluated for stickiness. The results of the evaluation show that the beads prepared using the epoxidized palm oil according to the invention have at least 50% higher viscosity retention than the control beads.

[0068] The measurement of the above viscosity was carried out using the technique described in the publication "Role of Phenolic Tackifiers in Polyisoprene Rubber, F.L. Magnus and G.R. Ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com