Beer brewing method

A beer and wort technology, which is applied in the field of beer brewing, can solve the problems of insufficient oxygenation of wort, and achieve the effects of solving the difficulty of foam boiling, increasing the concentration, and not reducing the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Ingredients scheme: main and auxiliary material ratio (weight ratio): 60:40, 60% malt, 40% starch, 60% Australian malt and 40% domestic malt.

[0039] 2. Brewing process:

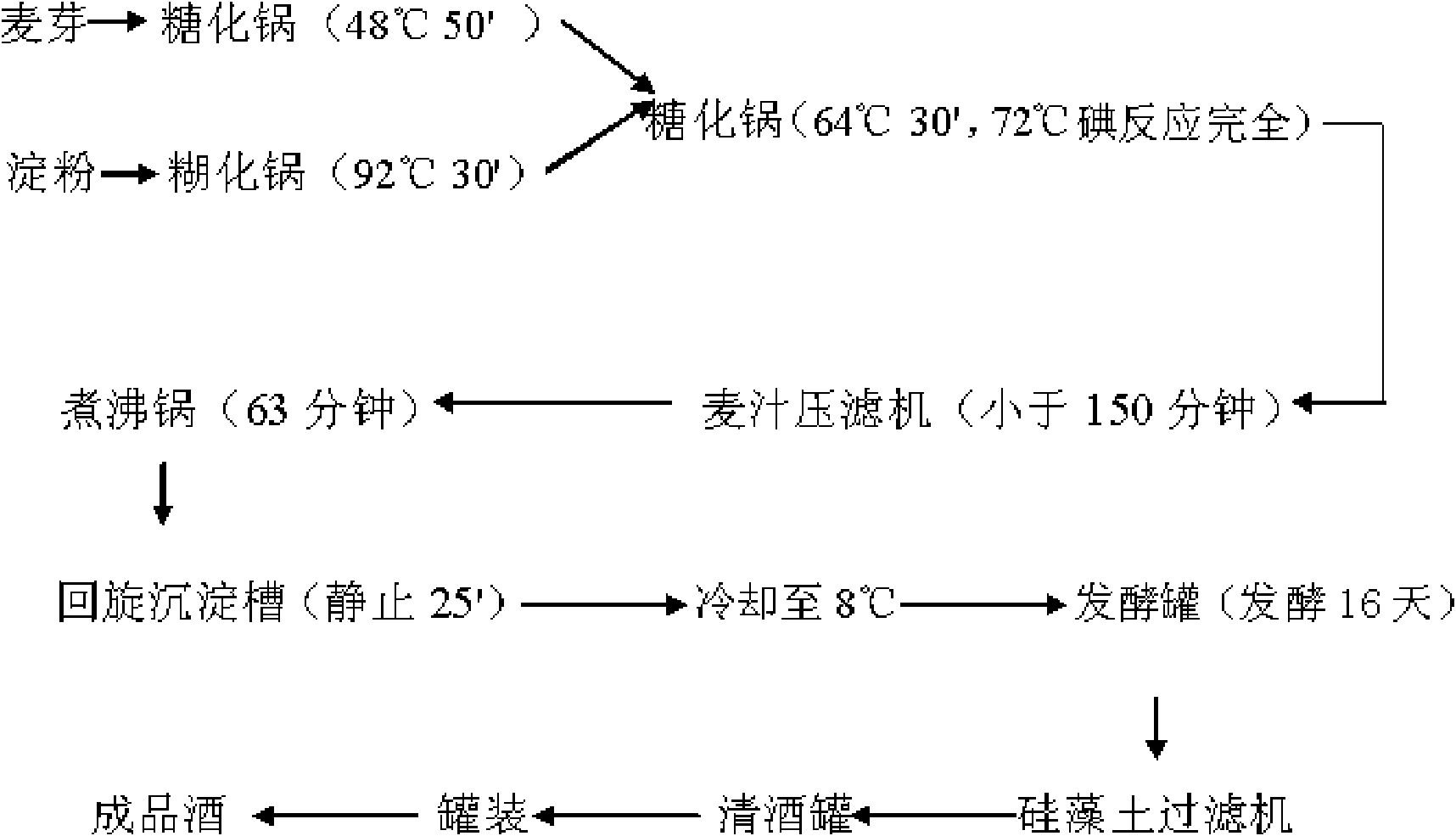

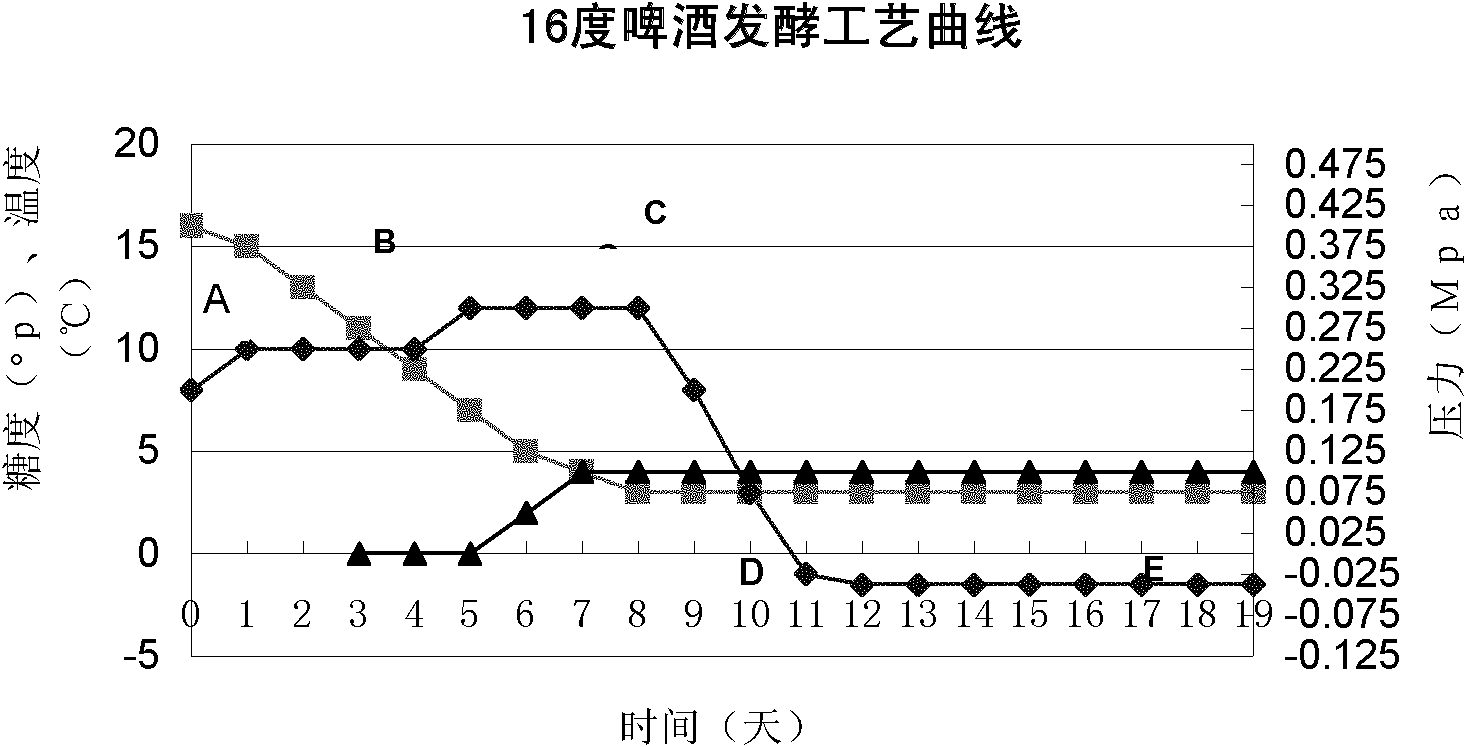

[0040] like figure 1 As shown, the brewing process of the present invention is divided into three steps, namely a saccharification step, a fermentation step and a filtration step.

[0041] 1) Saccharification step:

[0042] Put 5700KG of malt into the saccharification pot after being pulverized by a dry grinder and keep it at 48°C for 50 minutes for saccharification. Carry out heat preservation saccharification at 72°C. When the iodine reaction is complete, raise the temperature of the mash pot to 78°C. Use a filter press to filter the mash pot wort to the boiling pot. Use a temperature of 102°C to raise the pressure by 150mpa and lower the pressure by 50mpa for 6 times. The total time of stripping is 63 minutes. Low-pressure dynamic boiling, after boiling, pour it into the whirling tank for 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com