Clamping method for shaft parts and holding device

A technology of clamping device and shaft parts, which is applied to machine tools designed for grinding the rotating surface of workpieces, grinding workpiece supports, grinding machines, etc. Low efficiency and other problems, to achieve the effect of simple and convenient installation, low cost, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

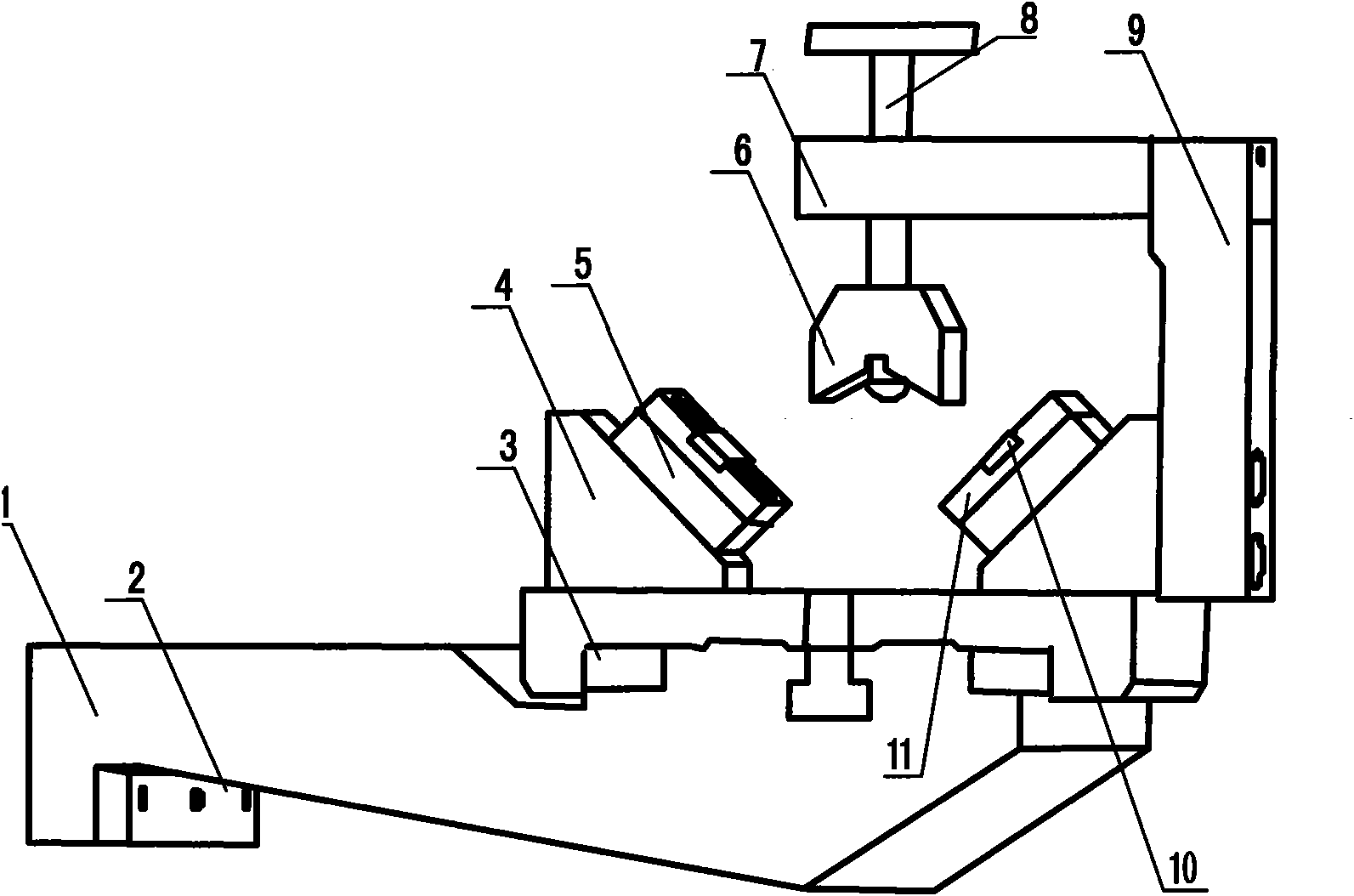

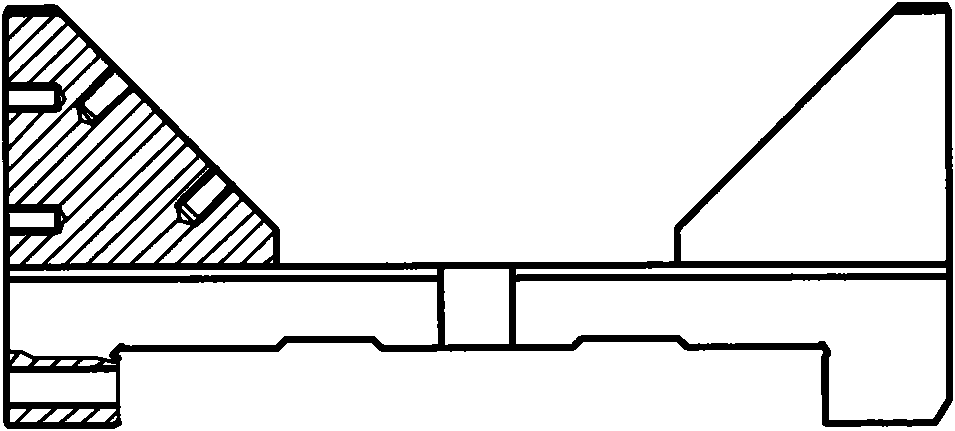

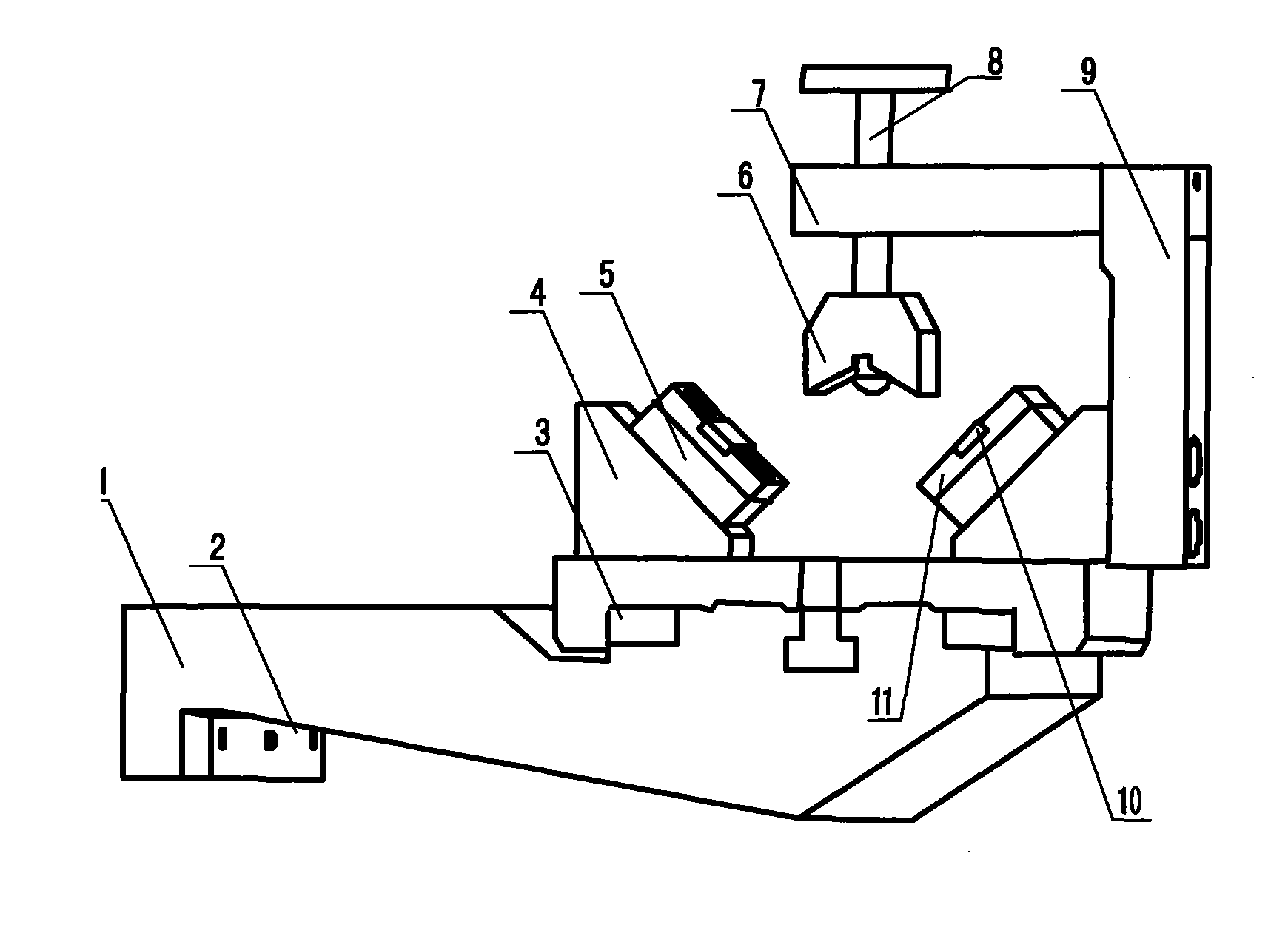

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] Such as Figure 1-Figure 2 As shown, the clamping method in the present invention is to place the workpiece on the small metal block 10 embedded in the center block 11 in the clamping device, and adjust the number and height of the small pads 5 to be consistent with the center height of the workpiece , to realize the radial positioning and centering of the workpiece, according to the size of the workpiece, the thread length of the adjusting bolt 8 can be adjusted until it is in close contact with the workpiece, and then tighten the screw hole on the fixing block 7 which is 90° from the hole in which the adjusting bolt 8 is installed The screw clamps and positions the workpiece axially and radially.

[0018] As shown in the figure, the clamping device of the present invention includes a clamp seat 1, an adjustment pad 2, a left and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com