Armature winding device capable of automatically adjusting balance

An automatic adjustment and armature winding technology, which is used in transportation and packaging, transportation of filamentous materials, thin material processing, etc. The effect of production efficiency and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

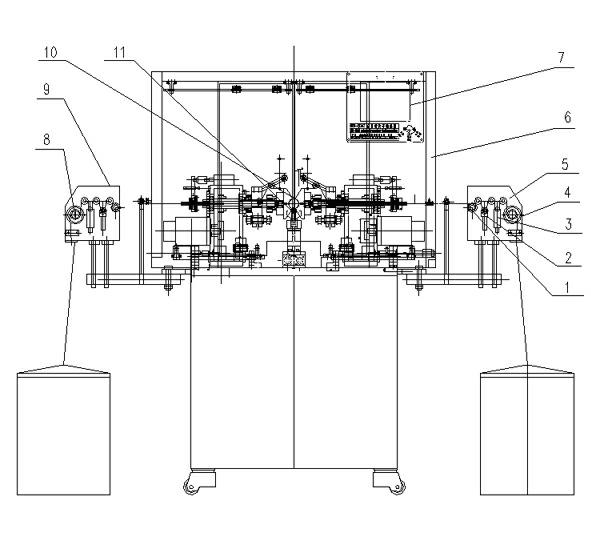

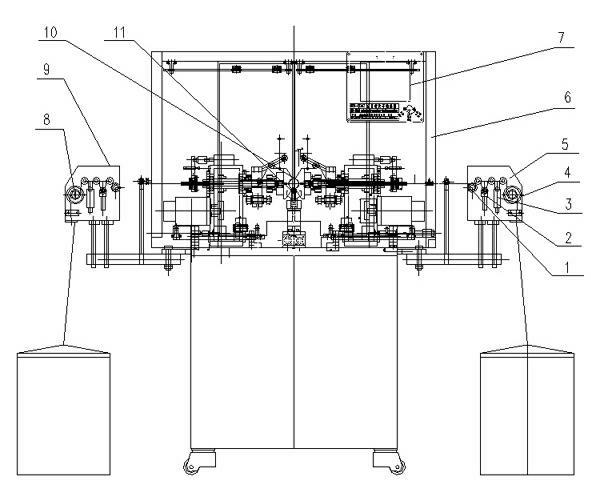

[0009] Below in conjunction with accompanying drawing, the present invention will be further described:

[0010] As shown in the figure, the armature winding device for automatically adjusting balance includes a body 6, a winding die 10, an armature 11, a controller 7, a first winding device and a second winding device, and the winding die 10 is arranged on On the body 6, a first winding device and a second winding device are respectively provided on both sides of the winding die 10, a left motor and a right motor are respectively arranged on both sides of the winding die 10, and the left motor and the The second motor is driven and matched, and the right side motor is driven and matched with the first motor. The first winding device is formed by the cooperation of the first motor 4, the first tensioner 5 and the first winding device. The second winding The device is formed by the cooperation of the second motor 8, the second tensioner 9 and the second winder, and the controll...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap