System and method for detecting energy consumption and productivity of machine

A detection system and machine technology, applied in the field of detection systems, can solve the problems of slow test speed, high price, poor development and application, etc., and achieve the effect of reducing impact and opening cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

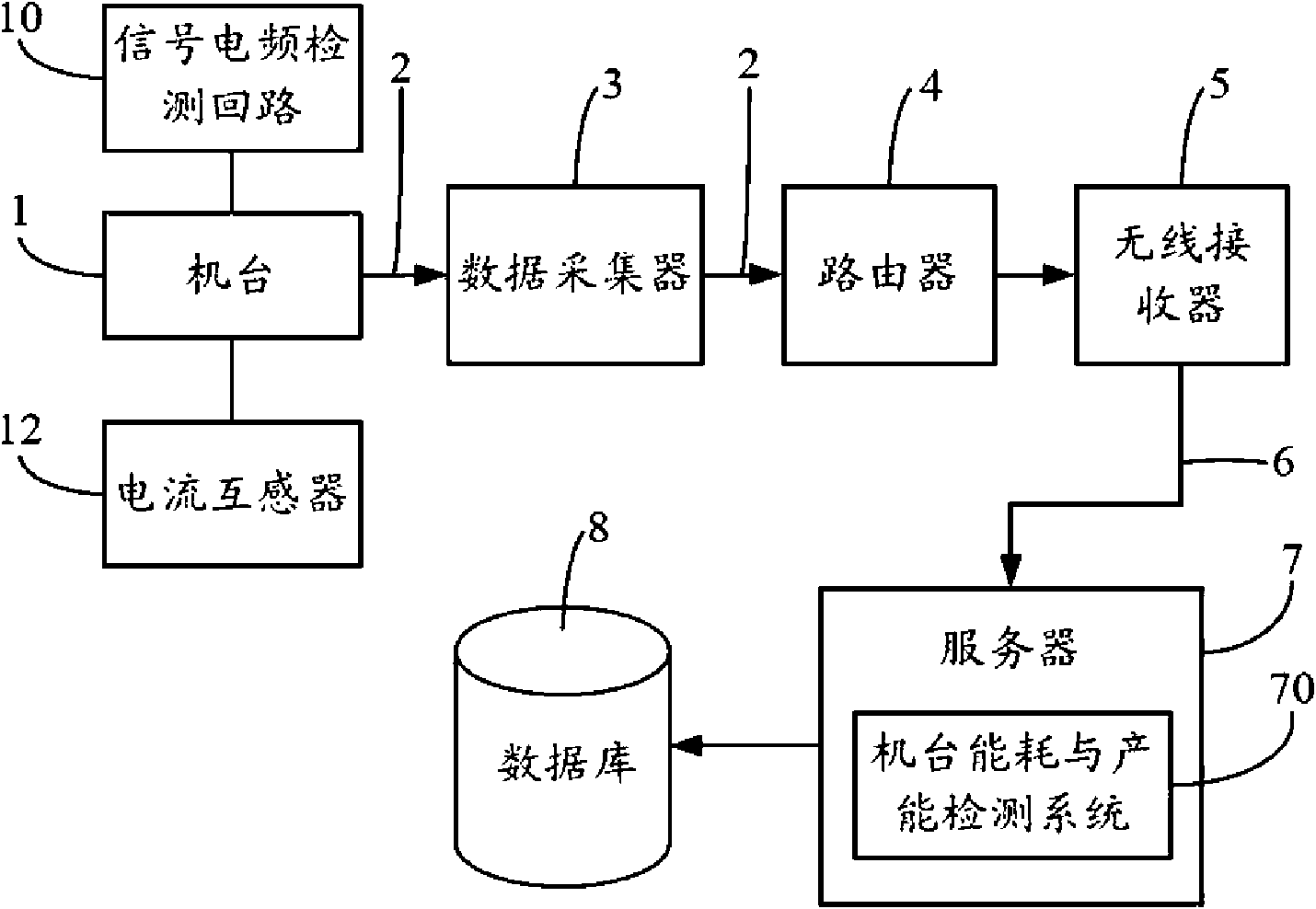

[0015] Such as figure 1 Shown is the operating environment diagram of the machine energy consumption and production capacity detection system of the present invention. The following combination figure 2 and image 3 The detection of machine energy consumption and production capacity in the present invention will be described.

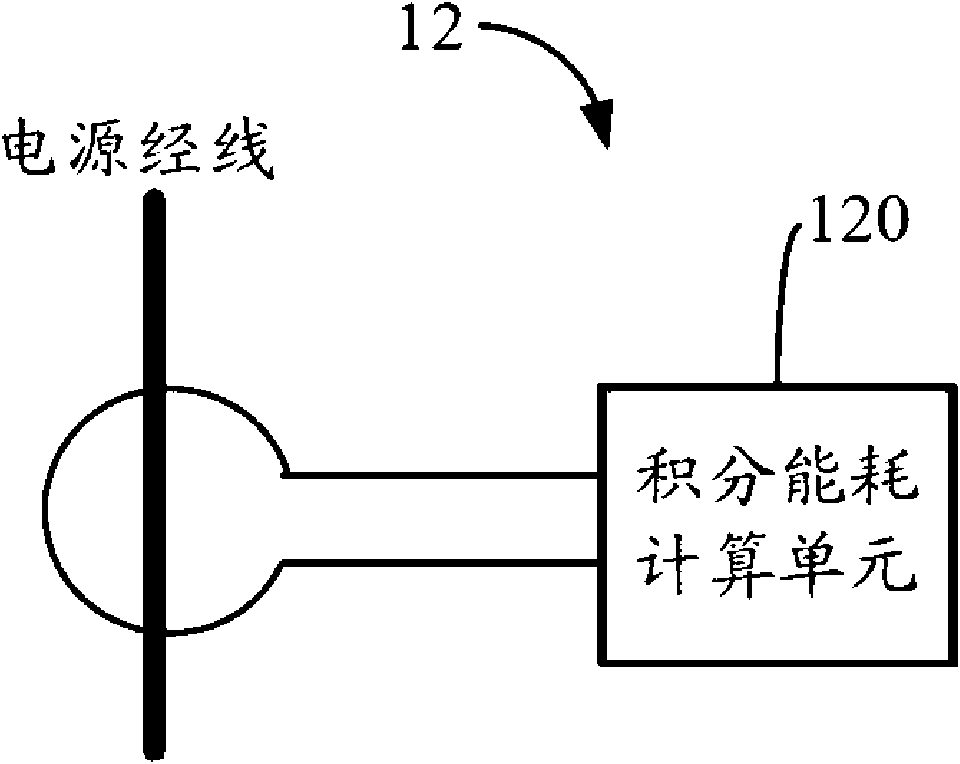

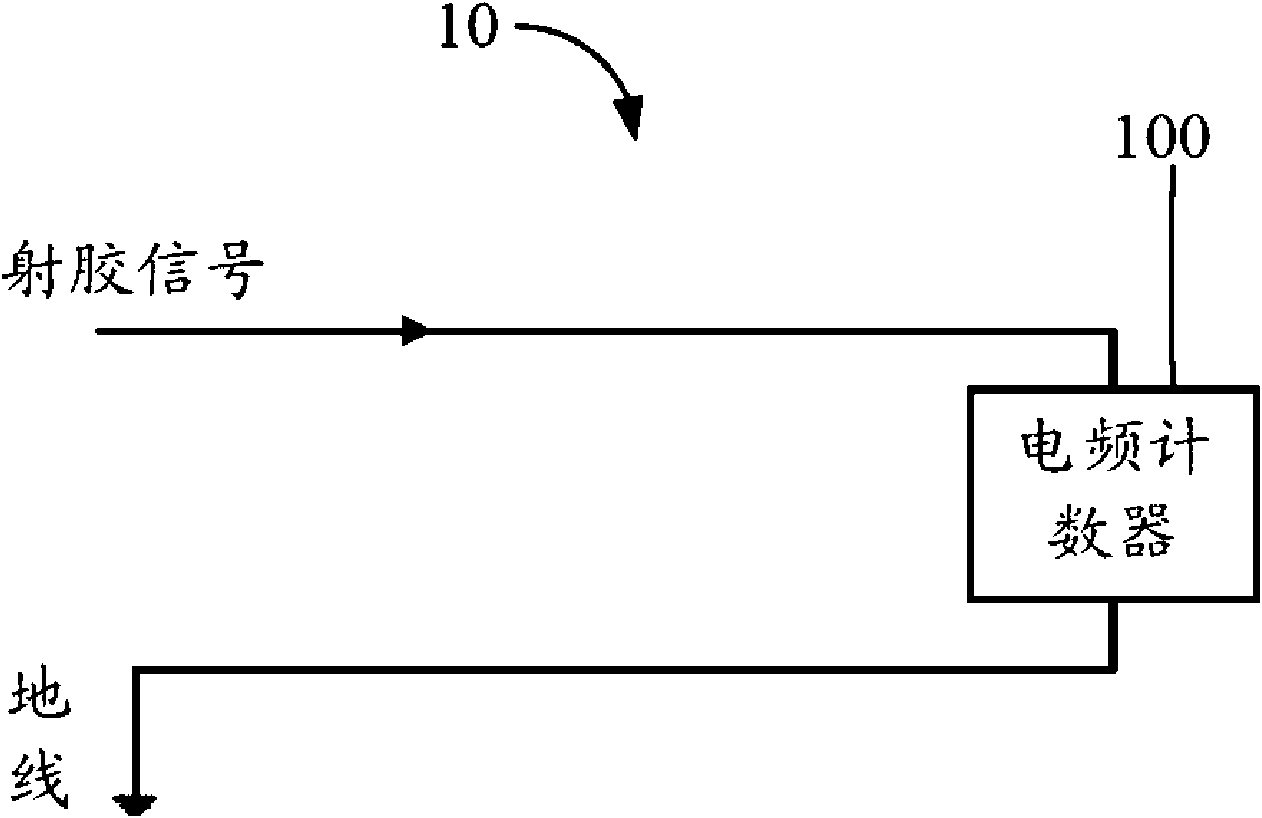

[0016] The operating environment includes at least one machine platform 1 (only one is shown in the figure), a signal electric frequency detection circuit 10 installed on the machine platform 1, a current transformer 12 ( Such as figure 2 shown), the data collector 3 connected to the machine 1 through the wireless network 2, the wireless receiver 5 connected to the data collector 3 through the wireless network 2, the server 7 connected to the wireless receiver 5 through the network 6 , and the database 8 connected with the server 7.

[0017] In the present embodiment, described wireless network 2 can be the wireless network that carries out ZigBe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com