Run-preventing stockings and manufacturing method thereof

An anti-stripping and stockings technology, which is applied in socks, pantyhose, textiles and papermaking, etc., can solve problems such as slipping, unsightly wearing, and socks that can no longer be worn, so as to achieve easy melting and bonding and improve wearing comfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

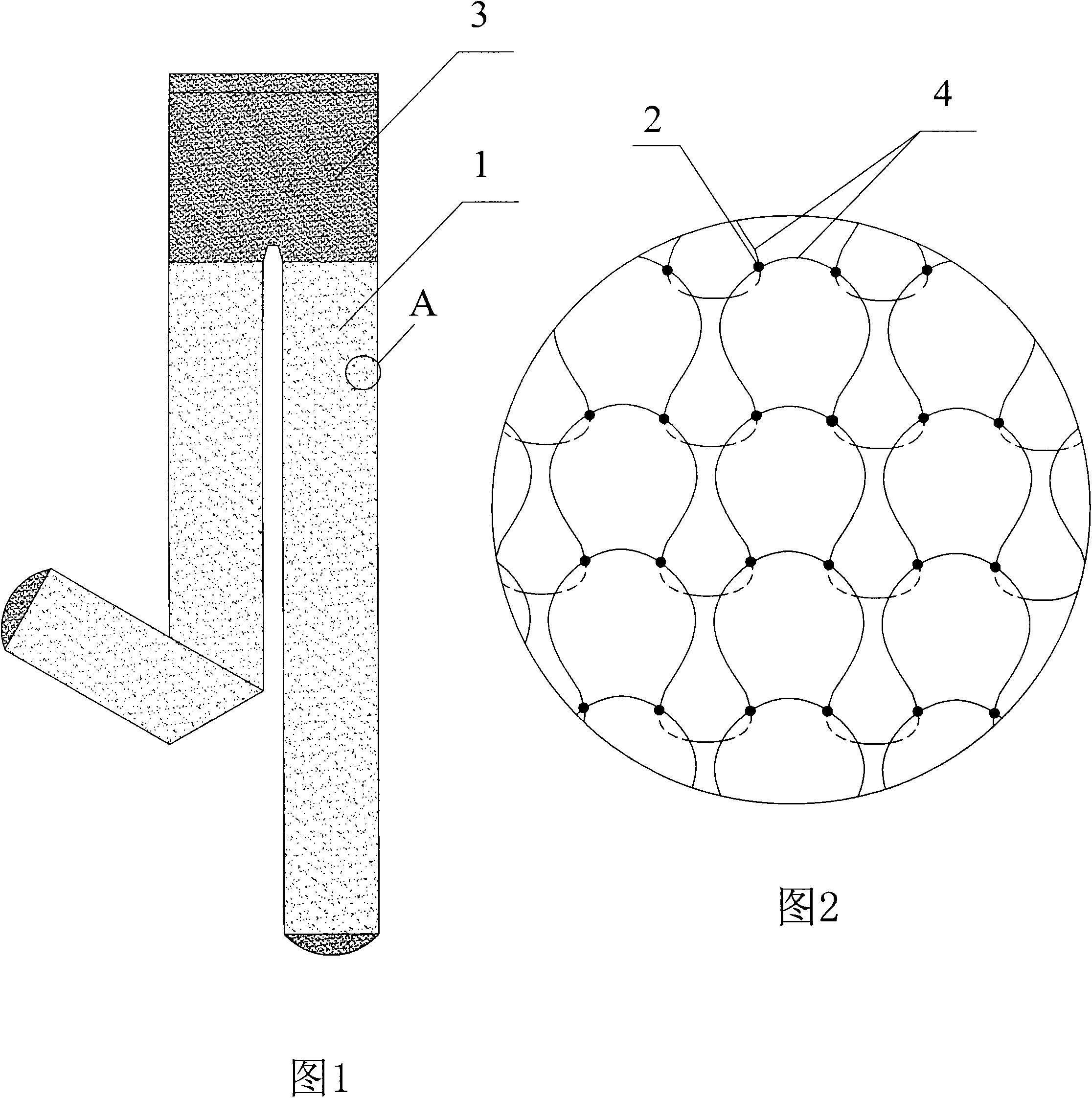

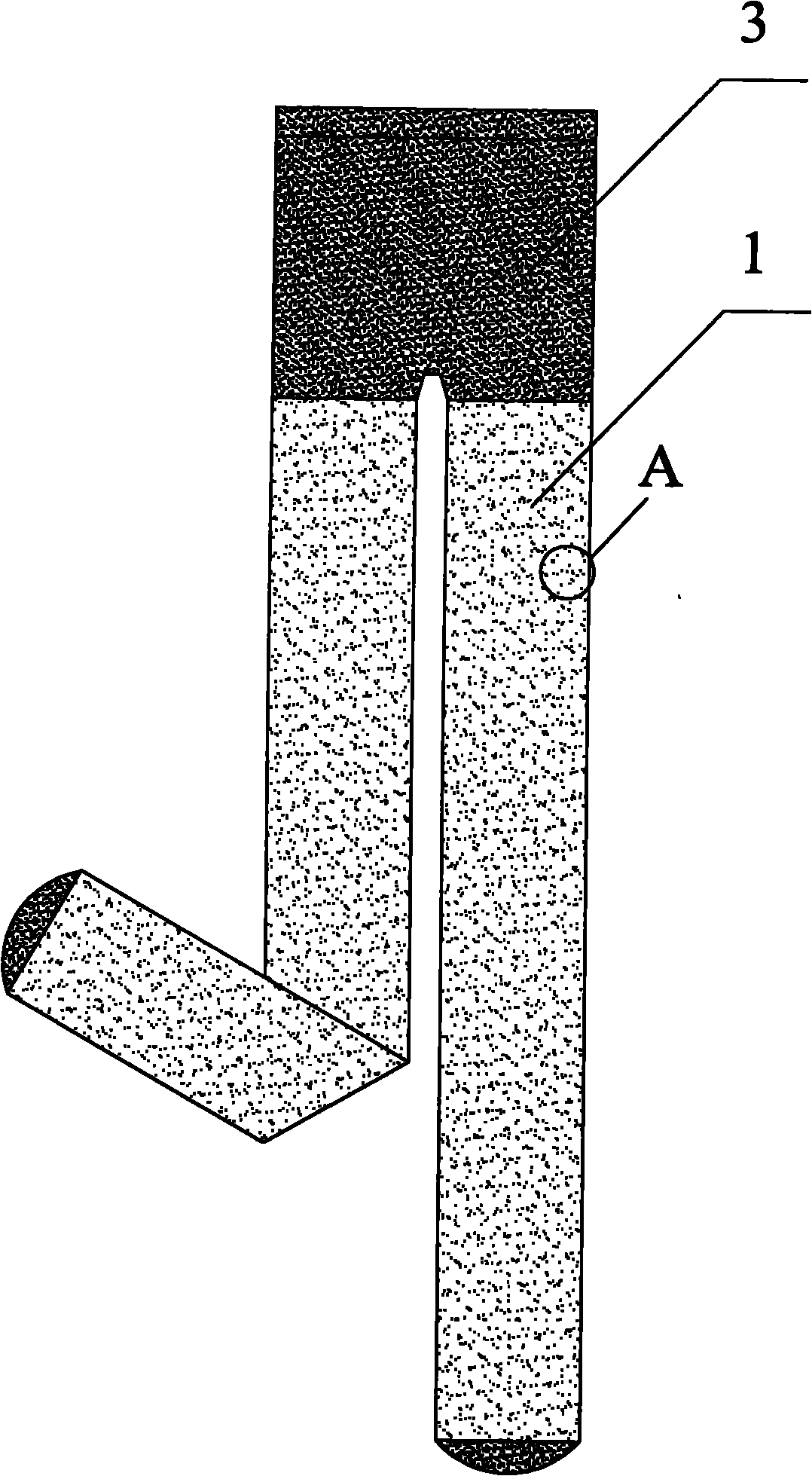

[0008] Referring to the accompanying drawings, the sock tube 1 of the stockings provided by the present invention is woven by a warp and weft knitting machine with 4 dissolvable spandex filaments, the spandex filaments can be selected from spandex filaments with a melting temperature between 140° and 180°. The denier of the spandex yarn is 8d-20d, and the weaving intersections 2 of the spandex yarn are melted and bonded.

[0009] The silk stockings described in this embodiment are pantyhose, and reference number 3 is the trousers body of the pantyhose, and the trousers body 3 and the sock tube 1 are connected through sewing. The stockings can also be stockings, stockings and the like.

[0010] In production, after the sock tube of the stockings is woven by a common weft knitting machine, it is then shaped at a high temperature of 140° to 180°, so that the weaving intersections 2 of spandex yarns are melted and bonded. Then be connected with trouser body 3 sewing again, also c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com