Contact lens without central moire pattern, method for analyzing changes in moiré pattern thereof, and monitoring system for changes in intraocular pressure

A contact lens and monitoring system technology, applied in tonometers, glasses/goggles, instruments, etc., can solve the problems of unfavorable carrying, error of measurement results, complex calculations, etc., and achieve the effect of avoiding damage or infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

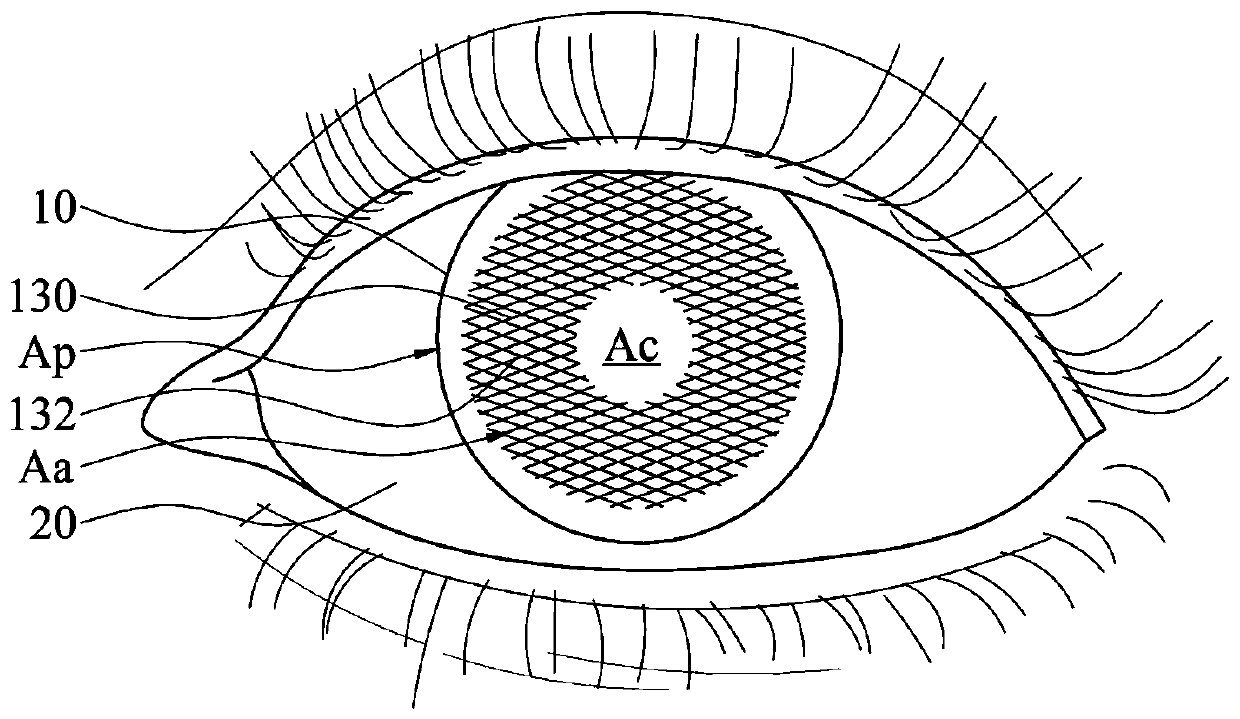

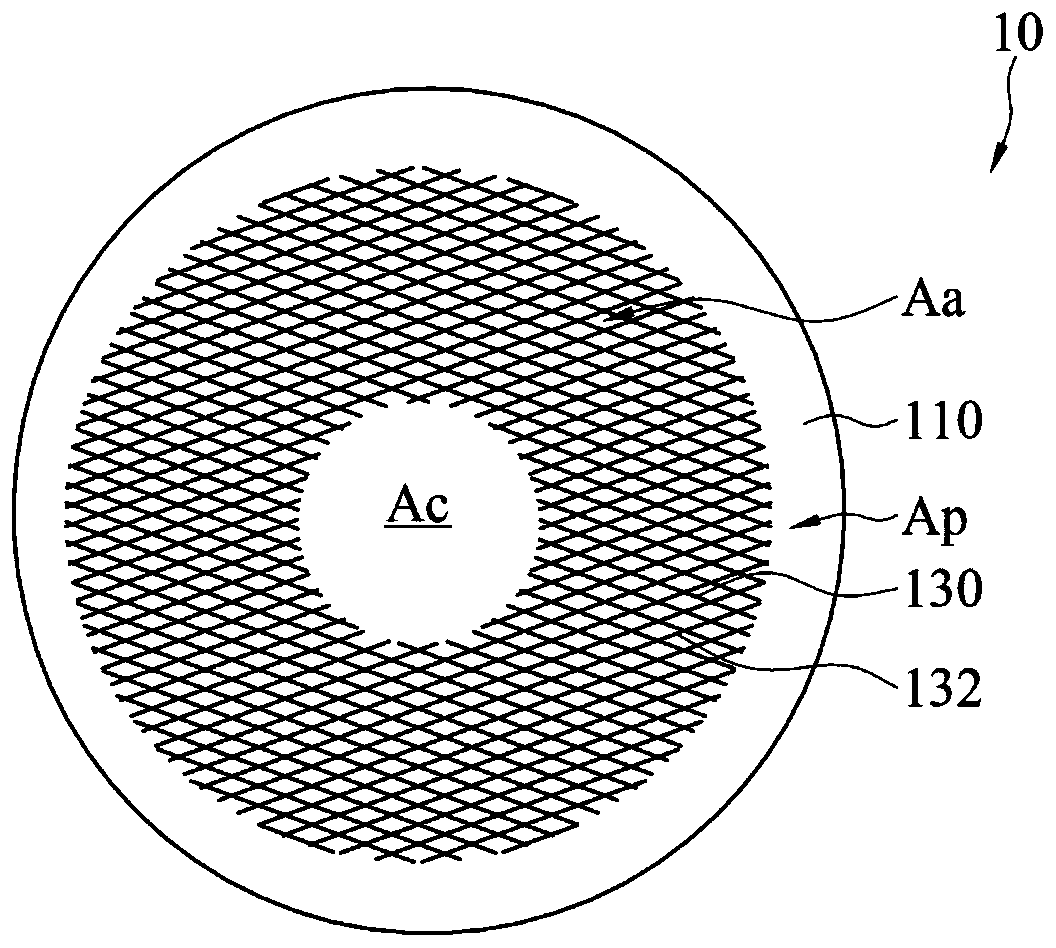

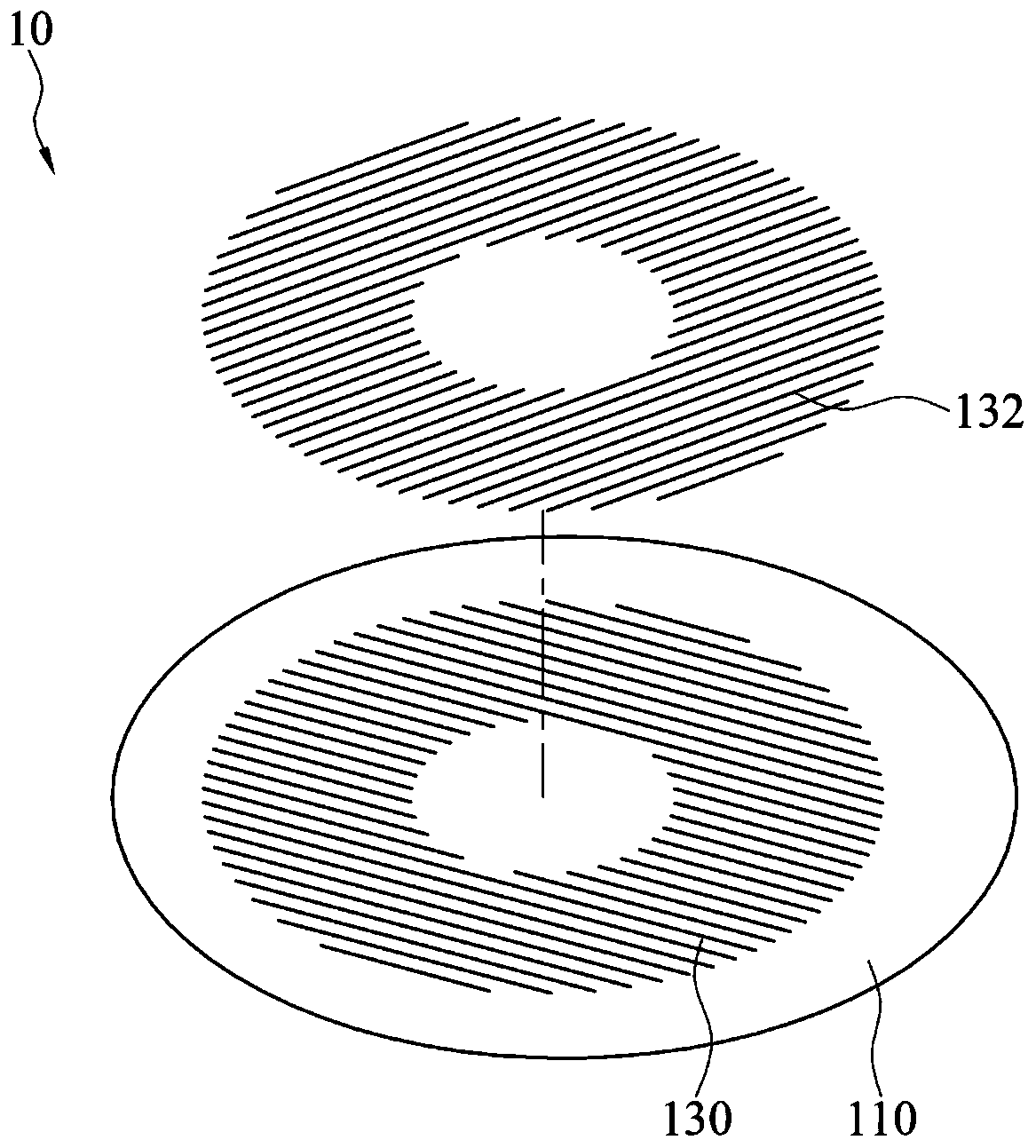

[0051] see Figure 1 to Figure 3 A contact lens with no moiré pattern in the center (hereinafter referred to as contact lens 10 ) is used to sense changes in intraocular pressure (IOP). The contact lens 10 includes a first material layer 110 and a pattern (hereinafter referred to as the first pattern 130 ). Here, the first material layer 110 is made of light-transmitting material. The first material layer 110 can be a hard contact lens material or a soft contact lens material. The first pattern 130 is formed by a plurality of sub-patterns (hereinafter referred to as first sub-patterns) arranged at intervals.

[0052] Looking down from the surface of the contact lens 10, the contact lens 10 has a central area Ac and an annular area Aa surrounding the central area Ac. When the contact lens 10 is placed on the surface of the eyeball 20 of the user, the central area Ac corresponds to the pupil of the eyeball 20 , and the annular area Aa corresponds to the iris of the eyeball 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com