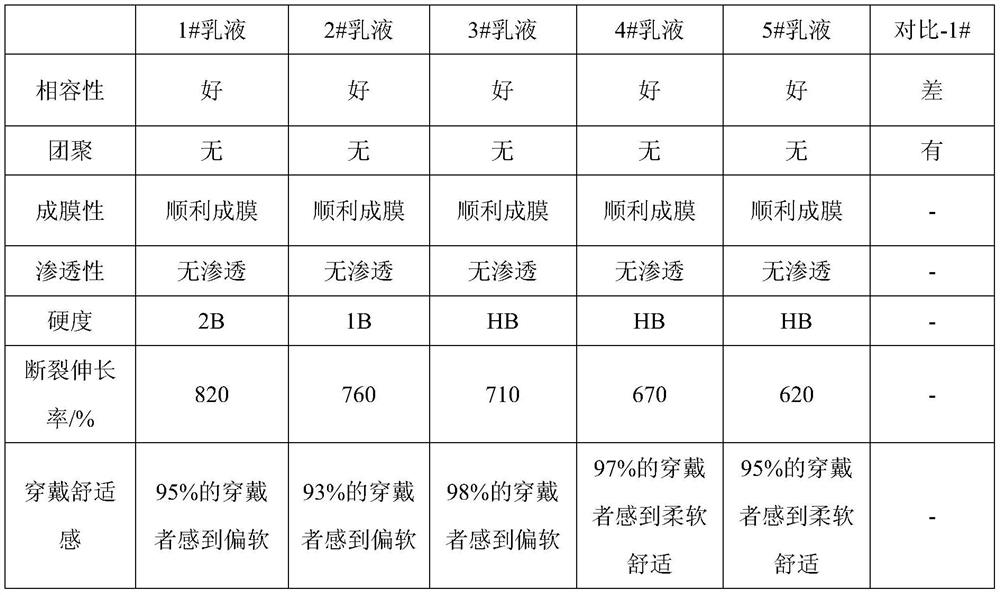

Solvent-free polyurethane dispersion with good compatibility with butyronitrile latex and emulsion for glove coating

A polyurethane dispersion and solvent-free technology, applied in polyurea/polyurethane coatings, coatings, conjugated diene coatings, etc., can solve the problems of PUD film-forming performance and other problems, and achieve easy finger movement, viscosity and particle size Moderate range, taking into account the effect of flexibility and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

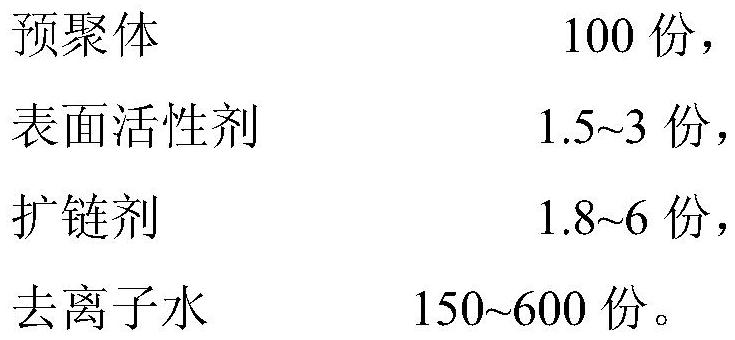

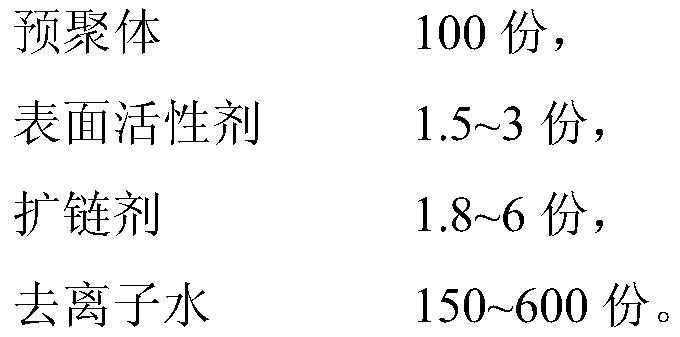

[0054] The preparation method of solvent-free polyurethane dispersion:

[0055] (1) Dry the macromolecular polyol and small molecular polyol, mix the dried macromolecular polyol and small molecular polyol with polyisocyanate, slowly raise the temperature of the system to 80-90°C, and the reaction time is 2-5 hours, a prepolymer was obtained.

[0056] (2) Mix the prepolymer, surfactant, chain extender and deionized water, stir at a high speed of 4000 to 6000rpm for 5 to 10 minutes, then reduce the speed to 300 to 600rpm, and continue to stir for 10 to 30 minutes to obtain Solvent based polyurethane dispersion.

Embodiment 1

[0058] Prepare a 1L three-neck flask, install a stirrer, a thermometer, nitrogen protection and a temperature control device. After drying, 56.2 parts of polyoxypropylene ether polyols (molecular weight 2000, functionality 2), 21.6 parts of polyoxypropylene ether polyols (molecular weight 3000, functionality 2), 1.3 parts of polyethylene glycol monomethyl ether (molecular weight 1000 , functionality 0.9) into the flask, mix well, then add 20.9 parts of 4,4'-diphenylmethane diisocyanate into the reaction flask, slowly raise the temperature to 80°C, and the reaction time is 5h to obtain 1# prepolymer, NCO % is 4%.

[0059] Take 100 parts of 1# prepolymer, 1 part of triethanolamine dodecylbenzenesulfonate, 2.47 parts of hydroxyethylethylenediamine and 600 parts of deionized water, stir at 4000 rpm for 10 minutes at high speed, then reduce to 300 rpm and stir for 20 minutes. A 1# solvent-free polyurethane dispersion was prepared, with an average particle size of 370 μm, a pH of 7...

Embodiment 2

[0061] Prepare a 1L three-neck flask, install a stirrer, a thermometer, nitrogen protection and a temperature control device. Add 68.6 parts of polyoxyethylene / oxypropylene ether polyols (molecular weight 2000, functionality 2) and 2 parts of polyethylene glycol monomethyl ether (molecular weight 1000, functionality 0.9) into the flask after drying, mix well, and then Add 29.4 parts of 4,4'-diphenylmethane diisocyanate into the reaction flask, slowly raise the temperature to 90°C, and react for 2 hours to obtain 2# prepolymer with an NCO% of 7%.

[0062] Take 100 parts of 2# prepolymer, 3 parts of triethanolamine dodecylbenzenesulfonate, 1.8 parts of hydroxyethylethylenediamine and 302 parts of deionized water, stir at 6000 rpm for 5 minutes, then reduce to 600 rpm and stir for 20 minutes. The 2# solvent-free polyurethane dispersion was obtained, with an average particle size of 100 μm, a pH of 7.13, and a solid content of 25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com