Ultramicro-fuse and manufacturing method thereof

A manufacturing method and fuse technology, which are applied in fuse manufacturing, emergency protection devices, electrical components, etc., can solve the problems of consuming large metal materials, unable to reduce costs, increase production costs, etc., and achieve the effect of avoiding arcing and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

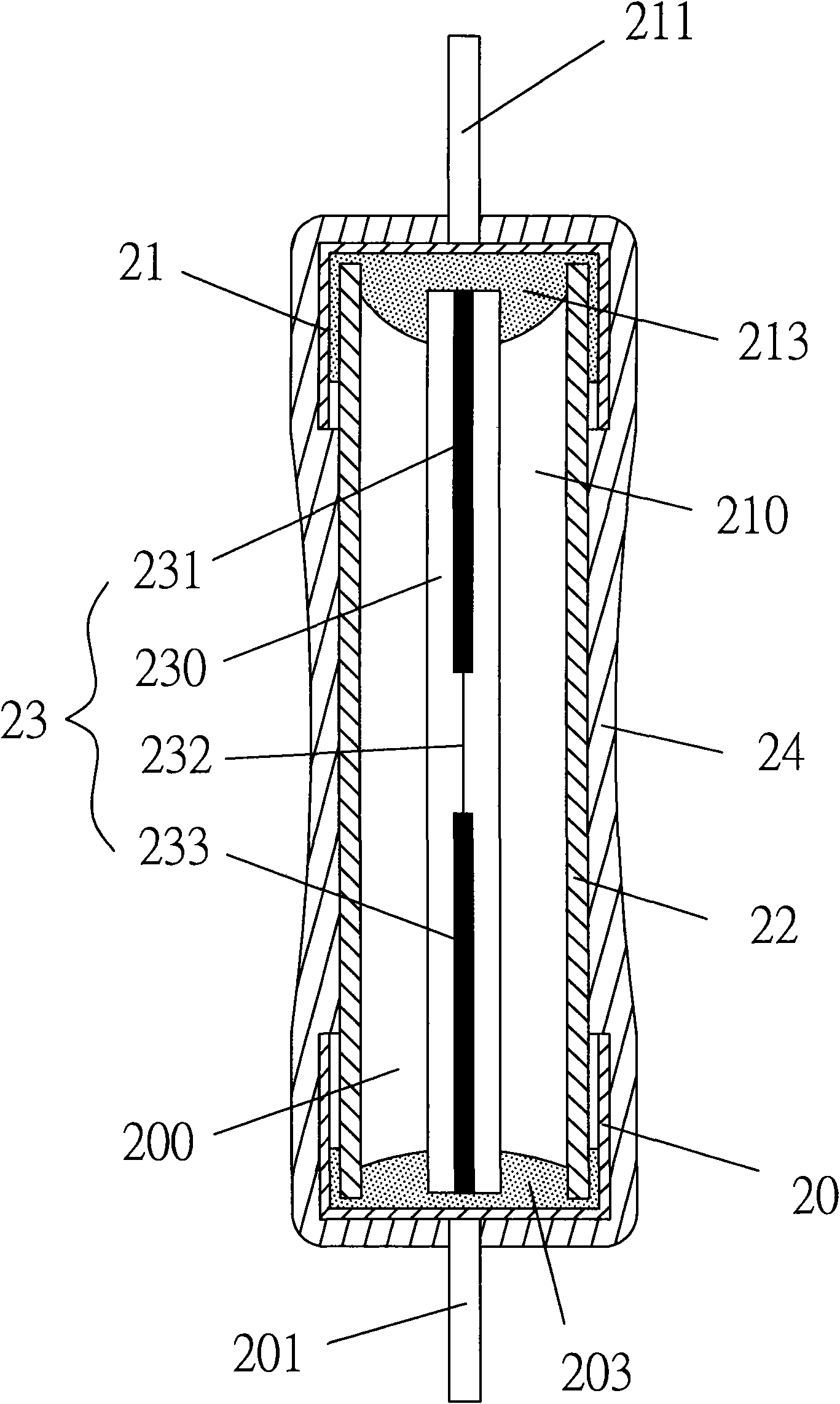

[0032] Please cooperate with reference image 3 As shown, the present invention is a first embodiment of an ultra-miniature fuse, which includes a first metal cap 20, a second metal cap 21, a tube body 22, a fuse 23, and an insulating layer 24.

[0033] The fuse 23 has a substrate 230, the substrate 230 is provided with a first electrode 233, a conductive portion 232 and a second electrode 231 that are electrically connected, and the fuse 23 is disposed in the tube body 22. The first electrode 233, the conductive portion 232, and the second electrode 231 are printed on the substrate 230 in a circuit printing manner.

[0034] The first and second metal caps 20, 21 are tightly closed on the two ends of the tube body 22, respectively. The first and second metal caps 20, 21 have grooves 200, 210 and end lines 201, 211. The grooves 200, 210 have The solder parts 203, 213 for the first and second metal caps 20, 21, the tube body 22 and the fuse 23 to be combined, wherein the first electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com