Panel loading apparatus and the method of loading panel for manufacturing display panel

A technology for loading equipment and display panels, applied in transportation and packaging, optics, instruments, etc., can solve the problem of large volume of the box 100, and achieve the effects of reducing manufacturing costs, maximizing space applications, and reducing quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] A panel loading apparatus and a panel loading method for manufacturing a display panel according to the present invention will now be described more fully hereinafter with reference to the accompanying drawings.

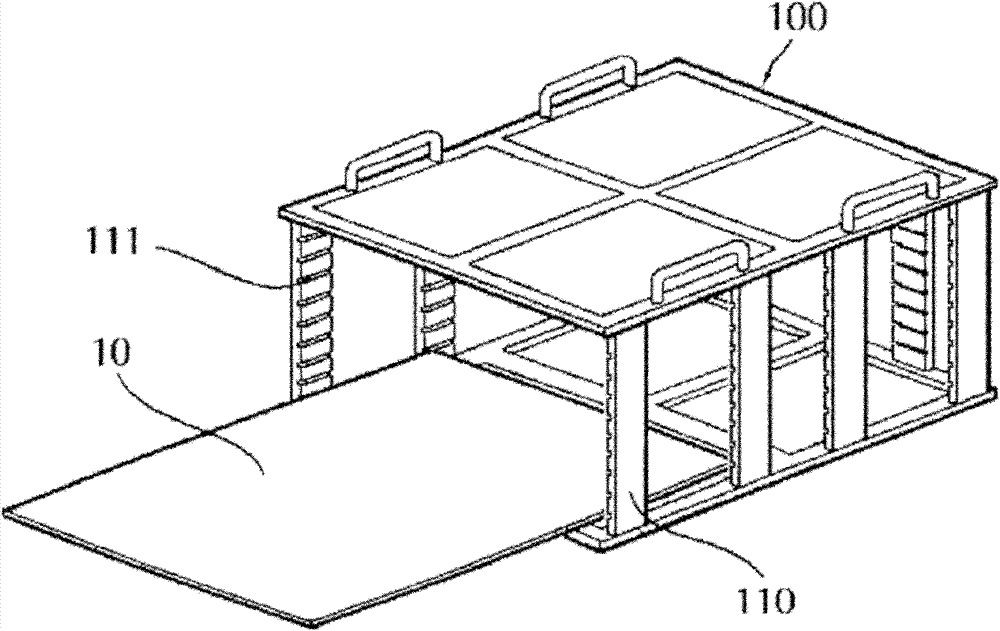

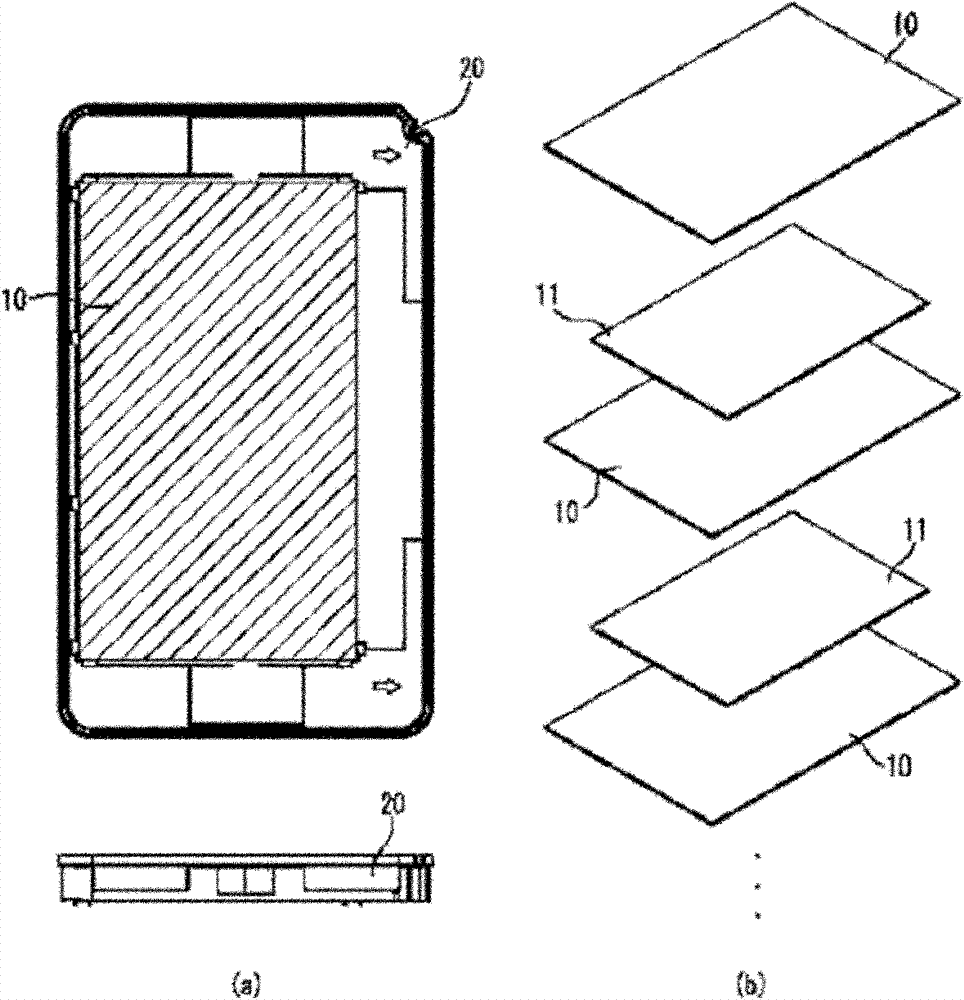

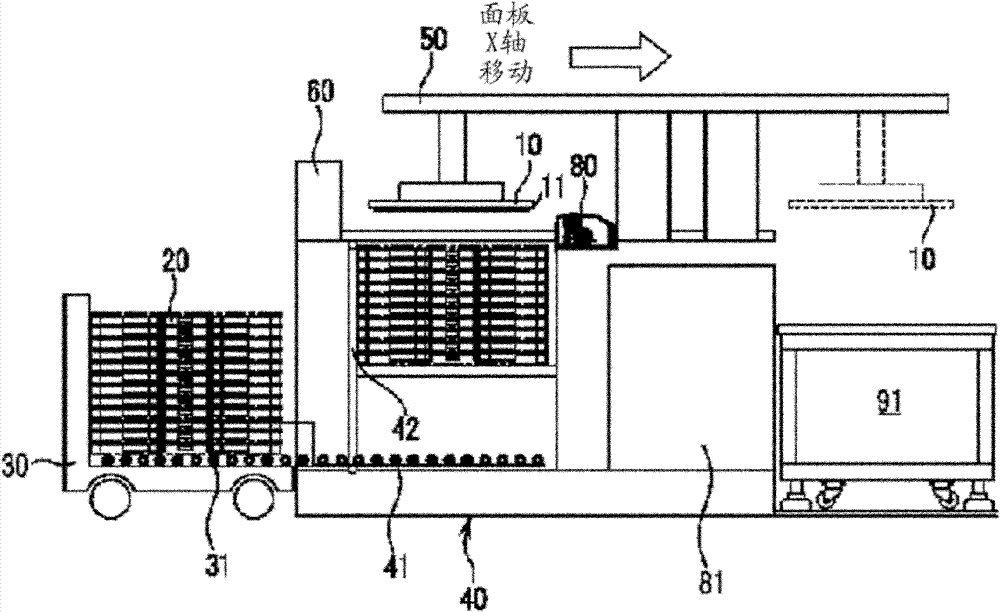

[0062] figure 2 is a diagram showing an exemplary embodiment of a pallet containing panels according to the present invention, image 3 is a diagram illustrating an exemplary embodiment of a process of transporting panels according to the present invention, Figure 4 is a diagram showing an exemplary embodiment of the process of transporting empty pallets according to the present invention, Figure 5 is a top plan view showing an exemplary embodiment of a panel loading apparatus for manufacturing a display panel according to the present invention, Figure 6 is a diagram showing an exemplary embodiment of a panel processing apparatus according to the present invention; Figure 7 is a diagram showing an exemplary embodiment of a tray discharging apparatus ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com