Valve timing control apparatus

A technology of valve timing control and timing sprockets, applied in valve devices, engine components, machines/engines, etc., can solve problems such as low feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

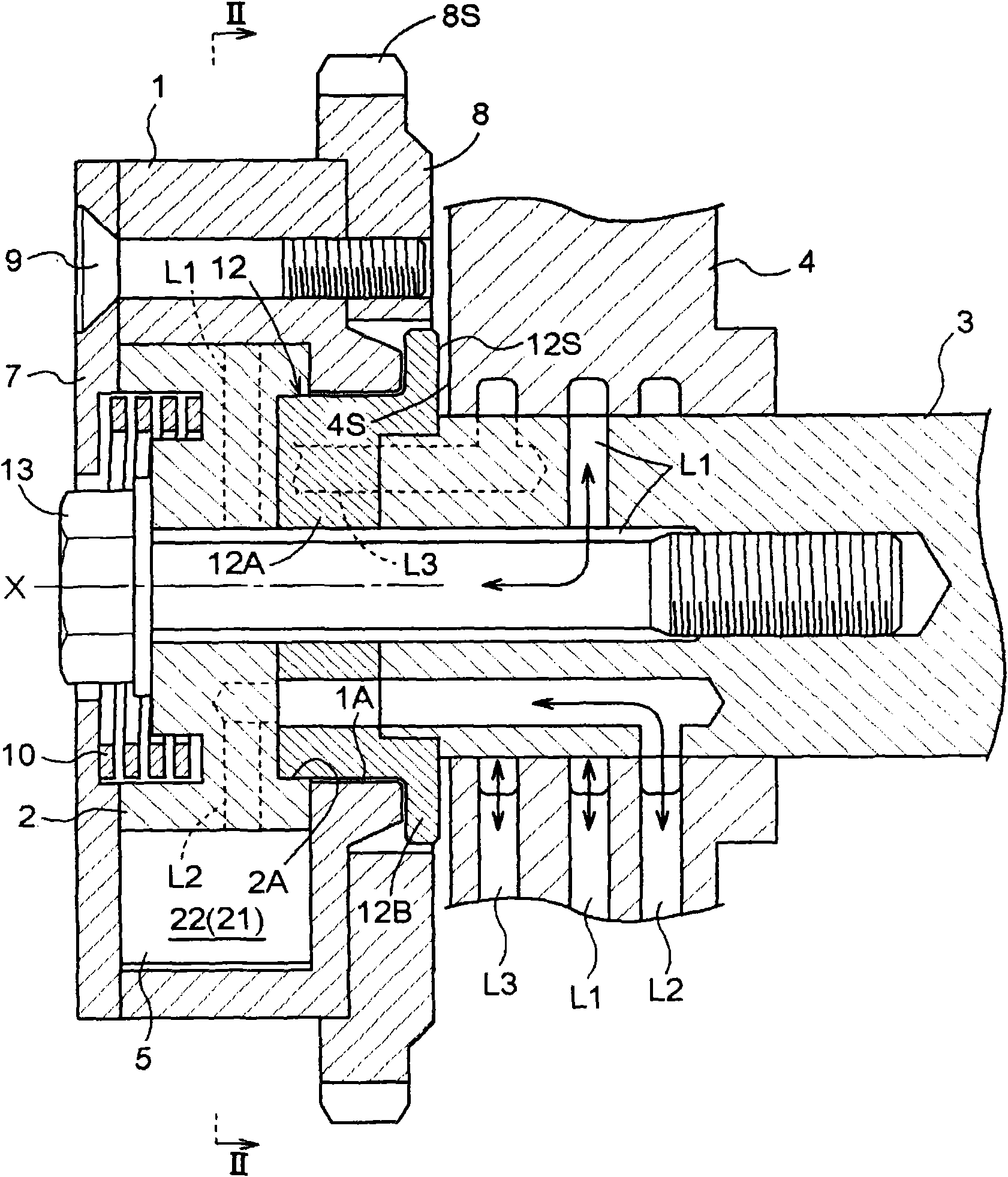

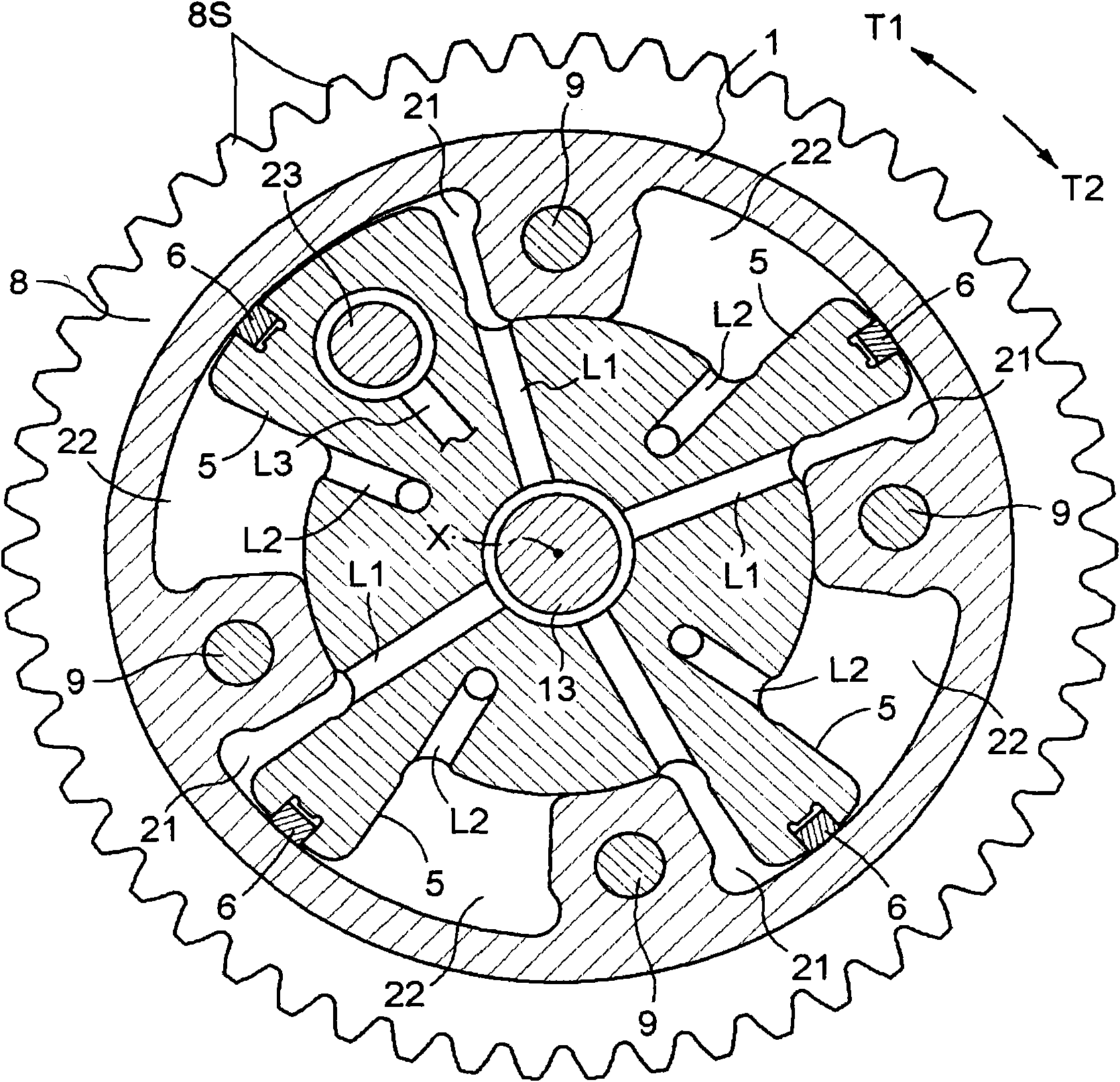

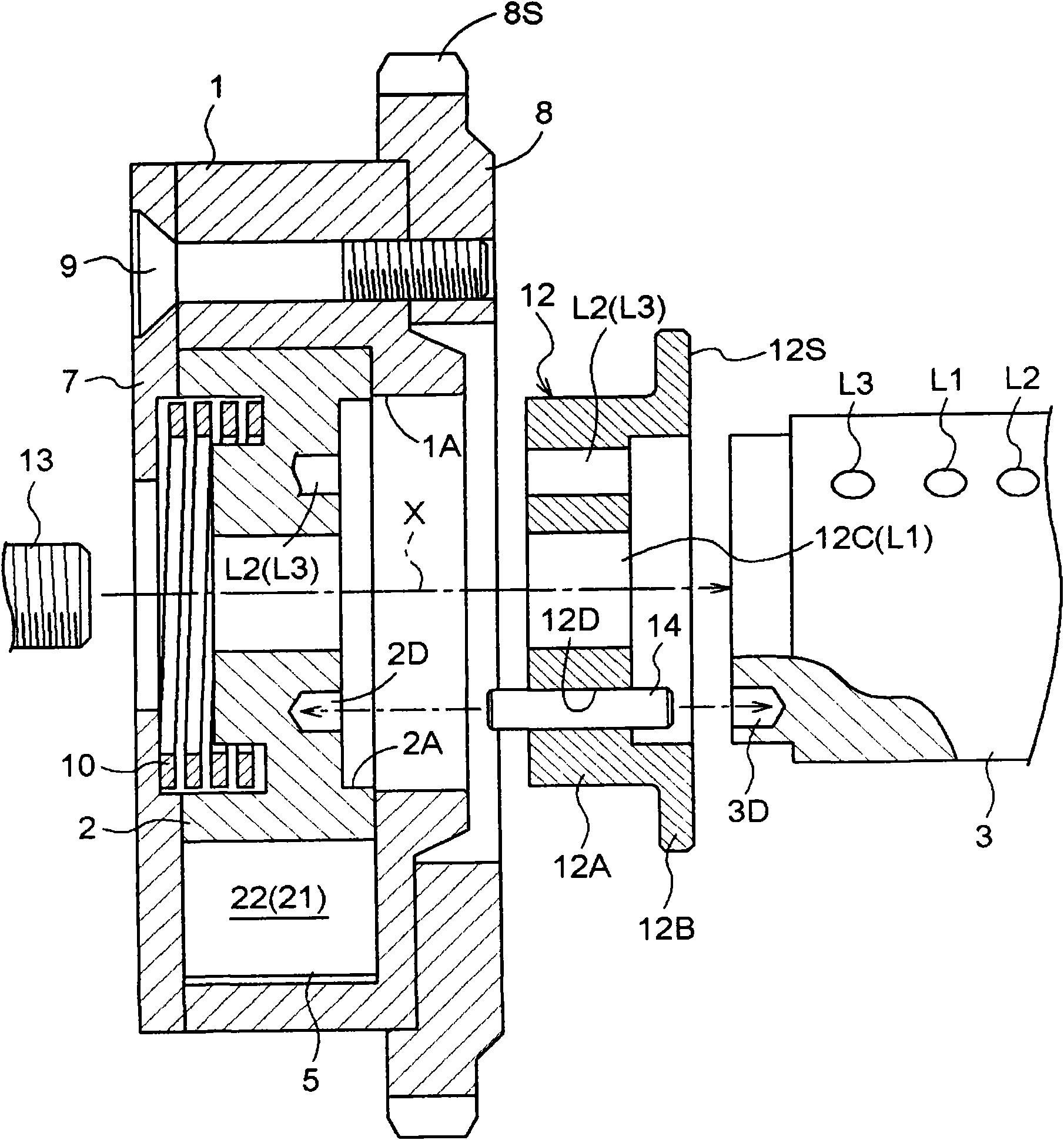

[0027] Embodiments disclosed herein are described with reference to the drawings. Such as figure 1 and figure 2 As shown, the valve timing control apparatus according to the present embodiment includes an outer rotor 1 as a driving side rotating member, an inner rotor 2 as a driven side rotating member, a retarded angle chamber 21 , and an advanced angle chamber 22 . The retarded angle chamber 21 and the advanced angle chamber 22 constitute and serve as a rotational phase adjustment device, by operating the supply and discharge of oil from the electromagnetic control valve relative to the retarded angle chamber 21 or the advanced angle chamber 22, to change or adjust the outer rotor 1 and the inner rotor. The relative rotational phase between 2. Via a timing chain, the outer rotor 1 rotates in a synchronous manner with the crankshaft of the engine, ie the internal combustion engine. The inner rotor 2 integrally rotates together with a camshaft 3 that opens or closes an int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com