High temperature high pressure dyeing machine

A high-temperature, high-pressure, dyeing machine technology, applied in the field of dyeing equipment, can solve the problems of insufficient simplification of the positional connection of components, inflexible settings, and reduced production efficiency, and achieves simple assembly, easy maintenance, flexible work, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

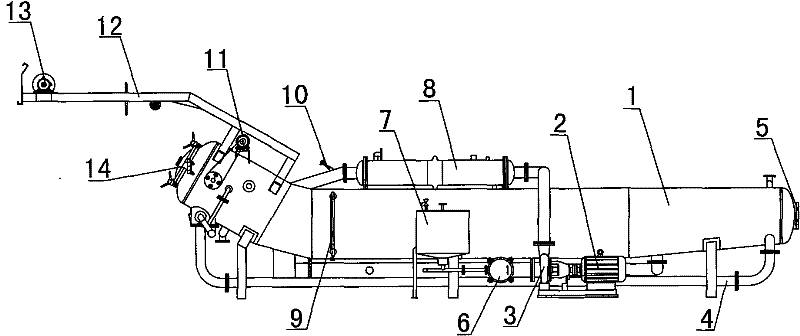

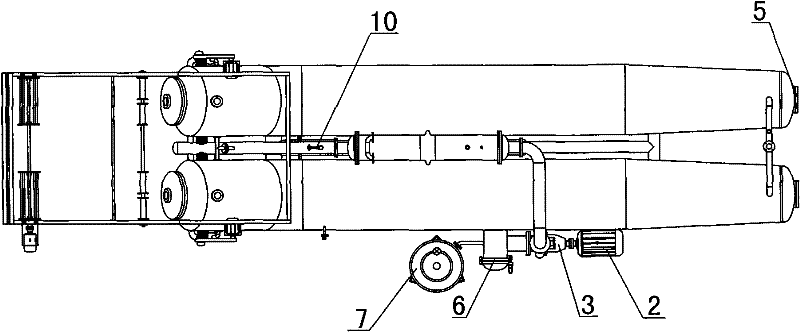

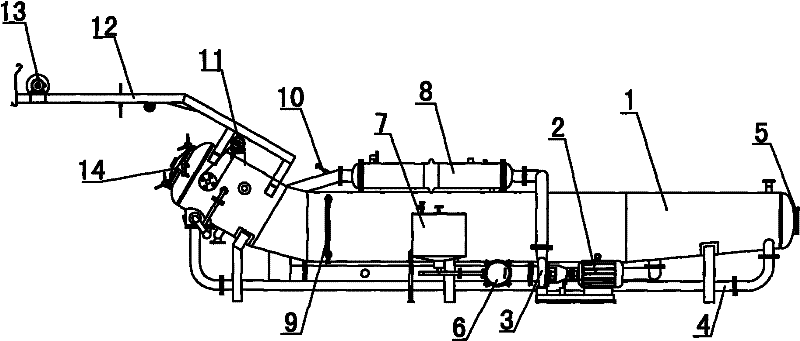

[0012] Such as Figure 1-2 As shown, the high-temperature and high-pressure dyeing machine of the present invention includes a dyeing tank body 1, a main pump 3, a filter 6, a chemical material cylinder 7 and a cloth outlet rack 12, and the dyeing tank body 1 is connected with a cloth guide pipe 4, and the dyeing tank body 1 The front and rear ends of the body 1 are respectively provided with a hand hole 5 and an operating port 14. A heat exchanger 8 is installed on the upper part of the dye vat body 1, and a main pump 3 and a temperature detector 10 are respectively installed on the pipelines at both ends of the heat exchanger 8. The main pump motor 2 is installed on one side of the pump 3, and a filter 6 is installed on the other side of the main pump 3, and the filter 6 is connected with the chemical material cylinder 7; The cloth outlet frame 12 is installed above the position, and the cloth lifting motor 11 and the cloth outlet motor 13 are respectively installed on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com