Vaporization pot

A technology for vaporizing pots and heating plates, applied in the field of vaporizing pots, which can solve the problems of elongated sealing rings, reduced sealing performance, and poor sealing performance, and achieve the effects of high strength, improved sealing performance, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

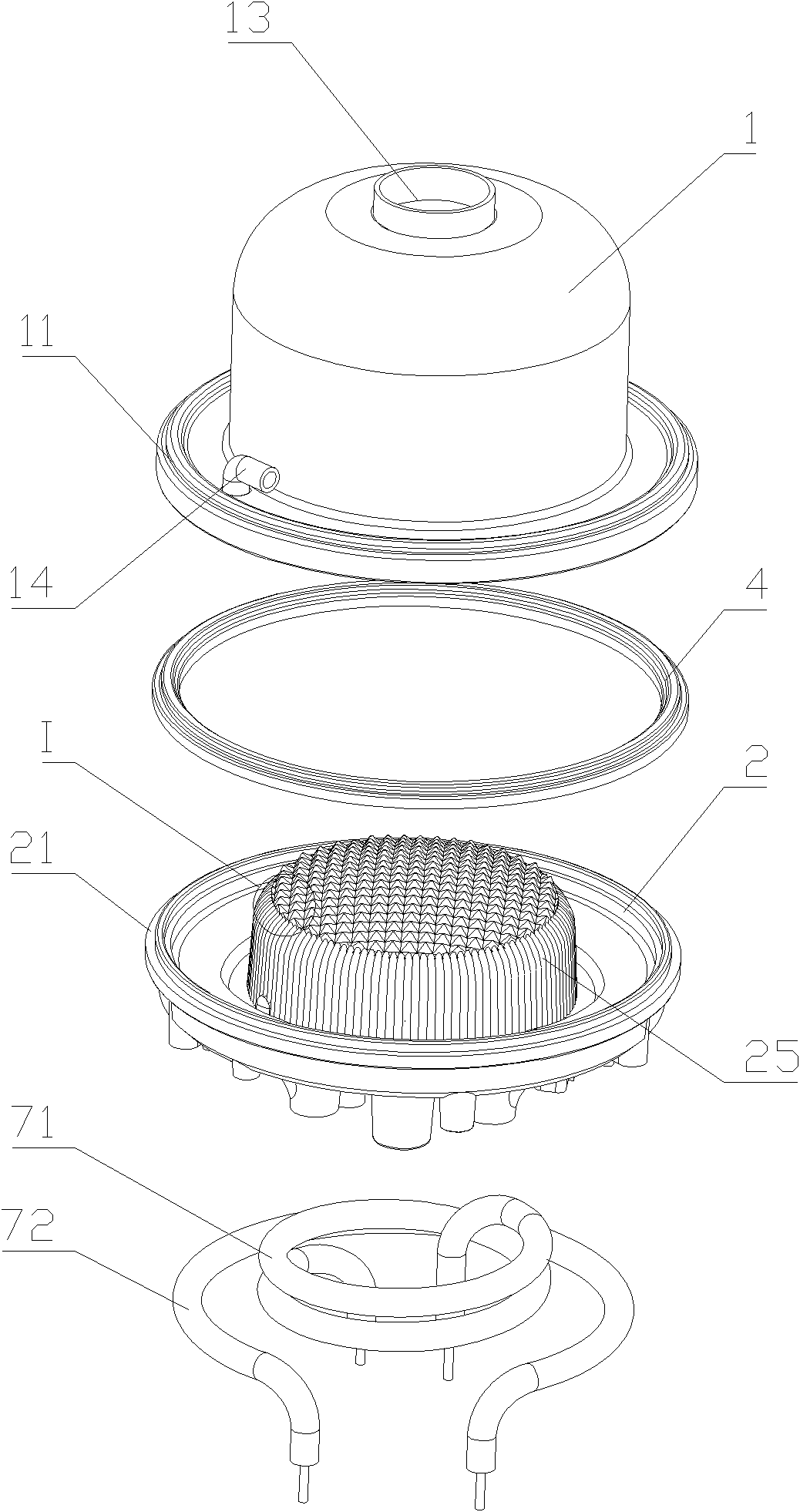

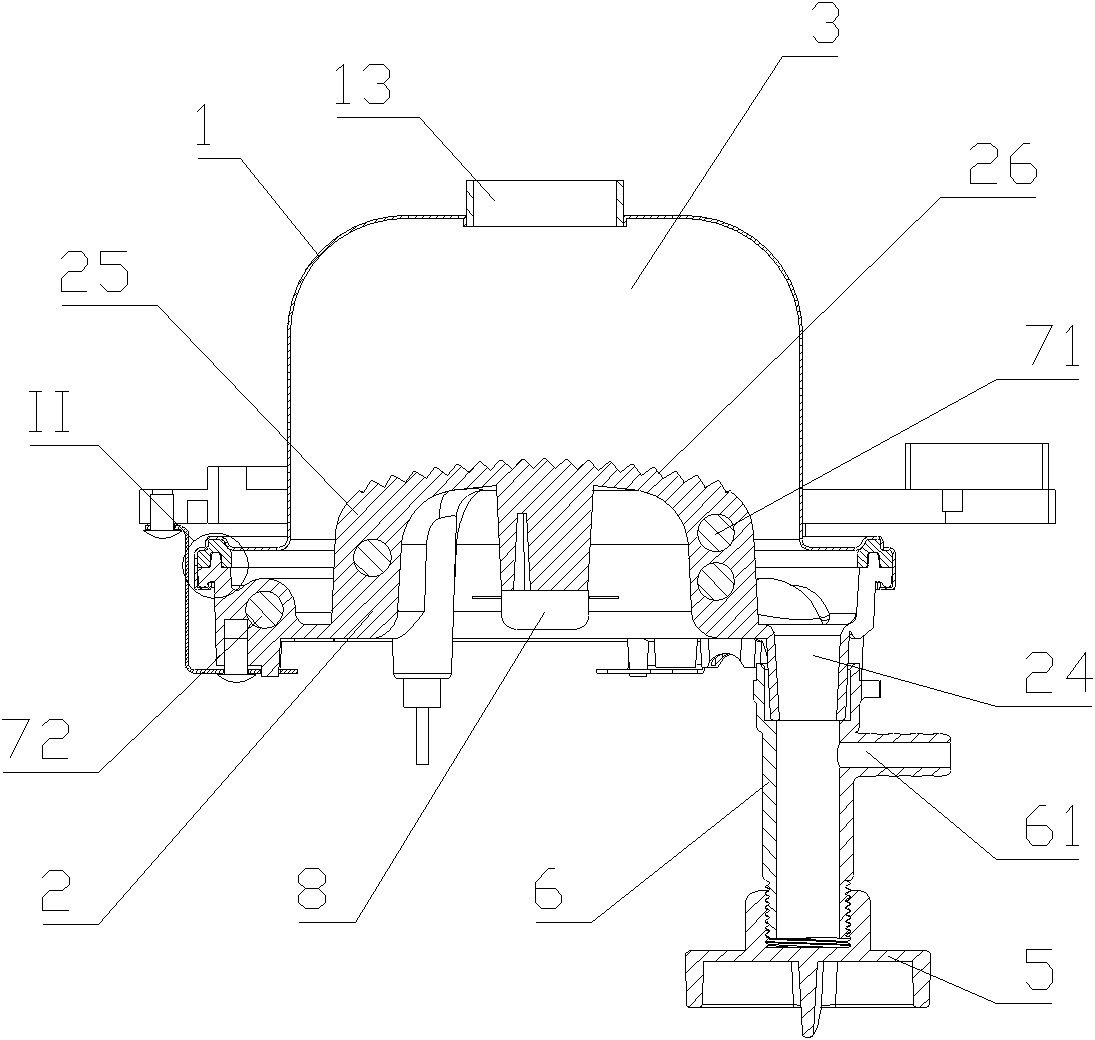

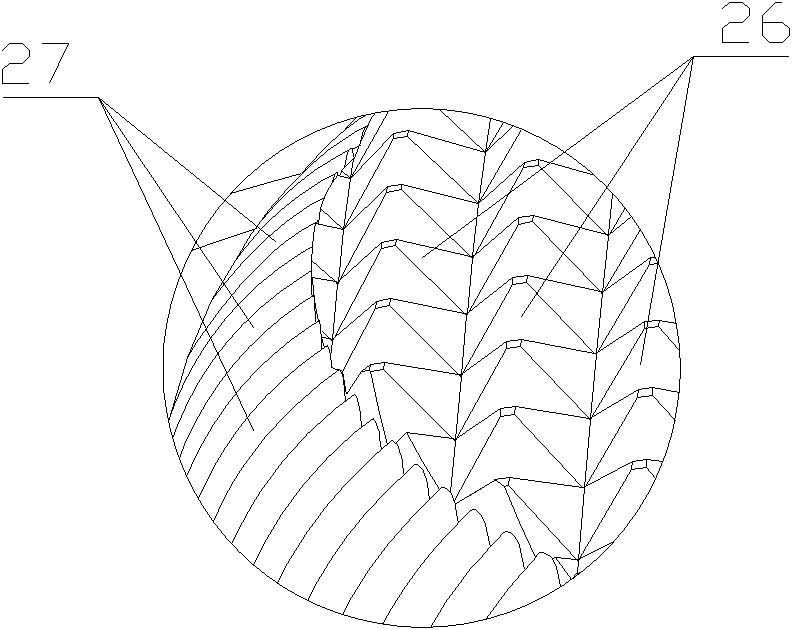

[0020] Such as Figures 1 to 4 Shown is a structural schematic diagram of an embodiment of the present invention, a vaporization pot, including a metal upper cover 1 and a heating plate 2, the metal upper cover is arranged on the heating plate and combined with the heating plate to form a vaporization chamber 3, the edge of the metal upper cover There is a flange 11, the edge of the heating plate is provided with a flange 21, and the outer edge of the flange is provided with a protruding body 22 extending downward, and the flange is folded downward and wrapped on the protruding body. A sealing ring 4 is arranged between the edges, and the sealing ring is directly placed between the folded edge and the flanging, and does not need to be tensioned and fastened for installation, so as to ensure that the sealing ring can be used in a natural state and prolong the service life. The flange is also provided with a positioning structure for positioning the sealing ring and increasing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com