Observation test device for mesoscopic and microscopic mechanical property and deformation of tailings

A test device and a technology for observing mechanics, which can be used in measuring devices, using stable tension/pressure to test the strength of materials, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

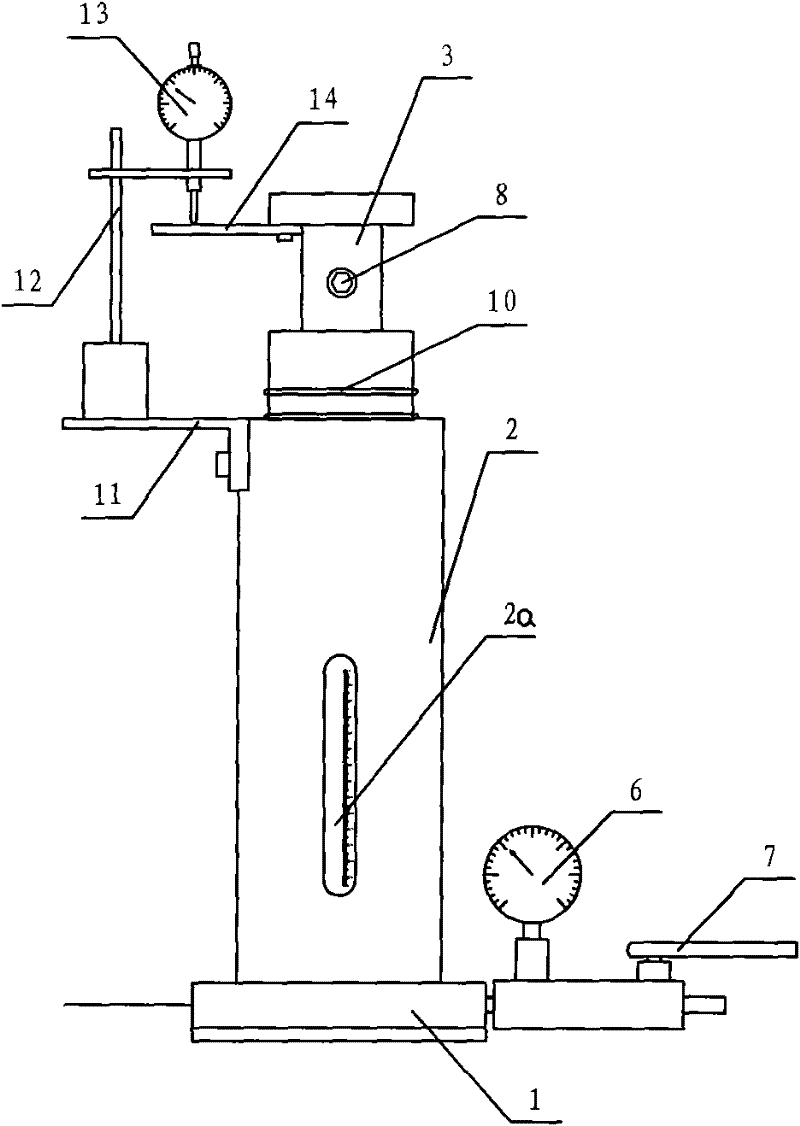

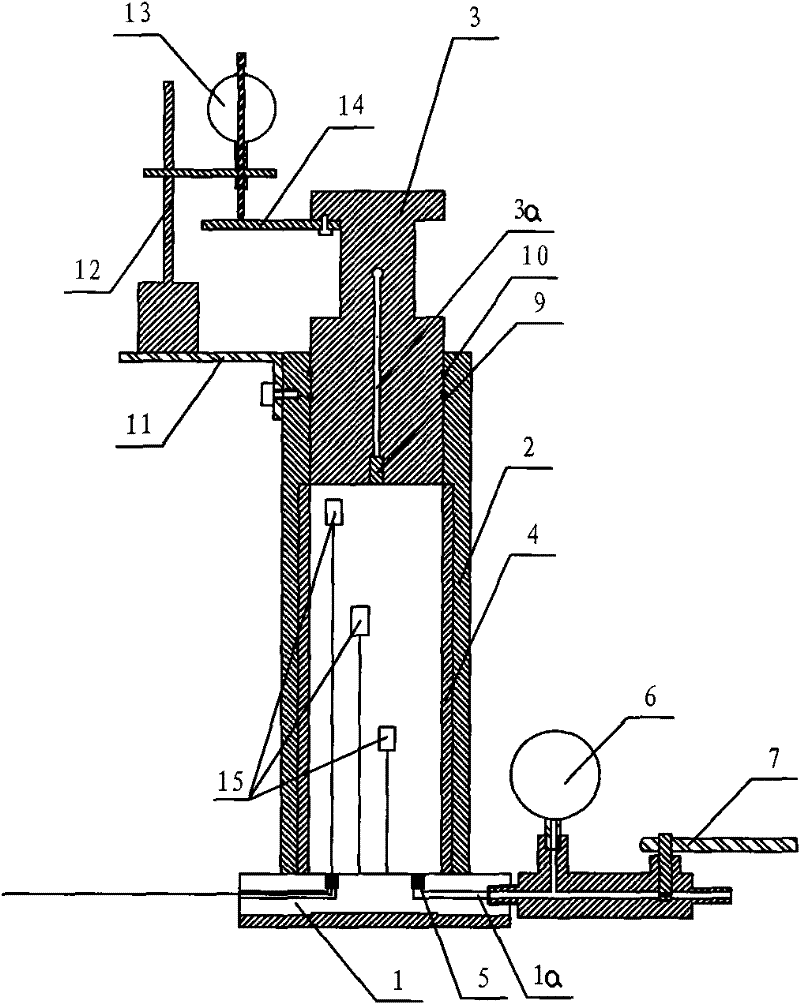

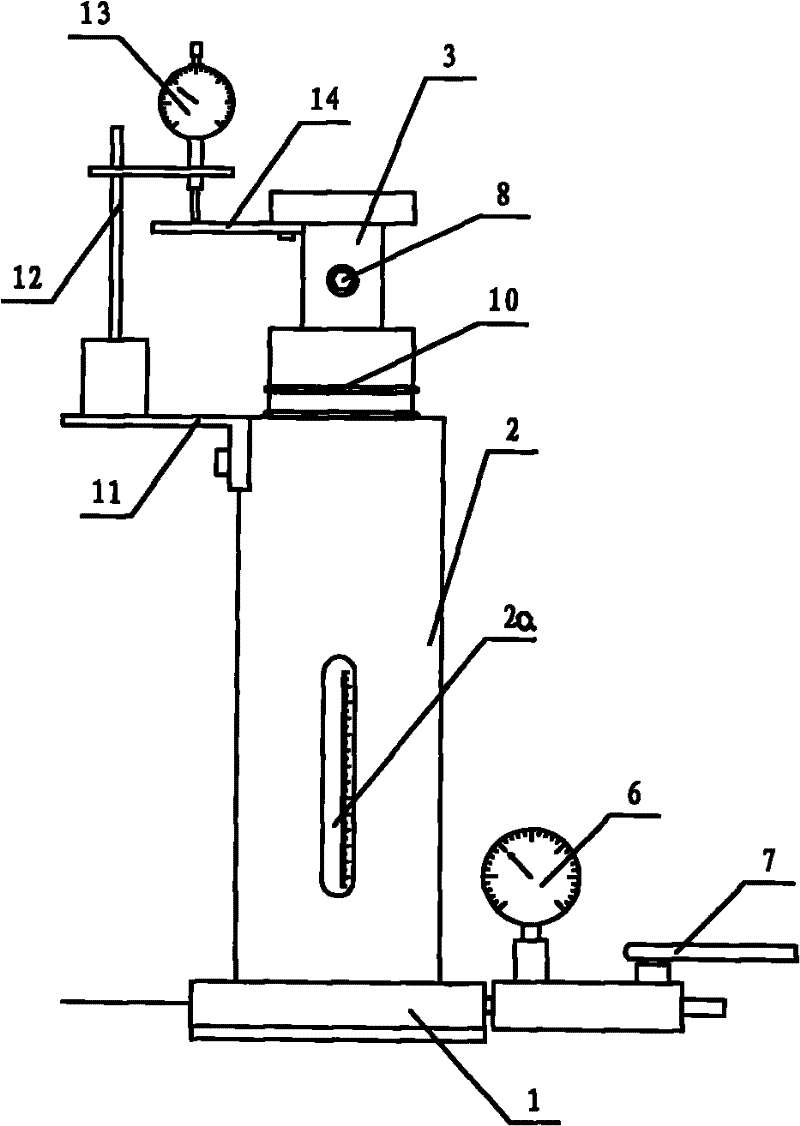

[0030] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0031] Such as figure 1 , 2 As shown, a tailings microscopic mechanical and deformation observation test device includes a pressure chamber 2 fixed on the base 1, and a pressurizing piston 3 extending from the mouth of the pressure chamber 2 into the pressure chamber 2, and The pressurizing piston 3 is tightly matched with the pressure chamber 2, and a pressure chamber is formed in the pressure chamber 2. The key is that: the side wall of the pressure chamber 2 is provided with an observation window 2a, and the inner wall of the pressure chamber 2 is provided with a ring for installation Groove, transparent observation tube 4 is installed in this mounting groove.

[0032] Using an electron microscope, the deformation of the microstructure of the tailings in the pressure chamber under pressure can be observed through the observation window 2a.

[0033] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com