Water filling and pressurizing device of steel pipe water pressure test

A technology of hydrostatic test and booster device, which is applied in the field of booster device and water filling, which can solve the problems of difficult tube removal and unreliable sealing, and achieve the effects of reliable sealing, high production efficiency, and convenient and reliable tube removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

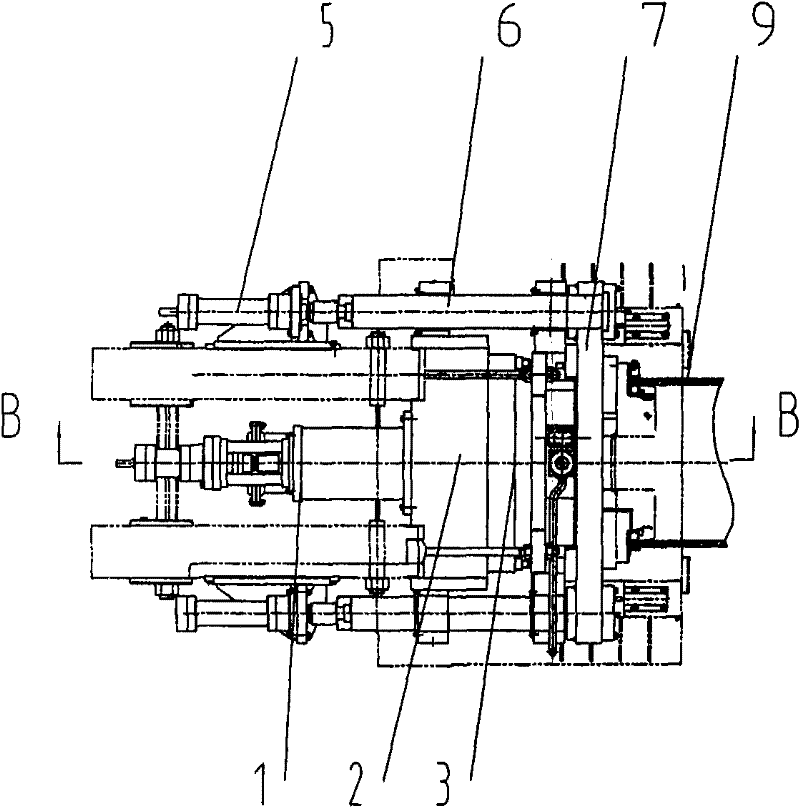

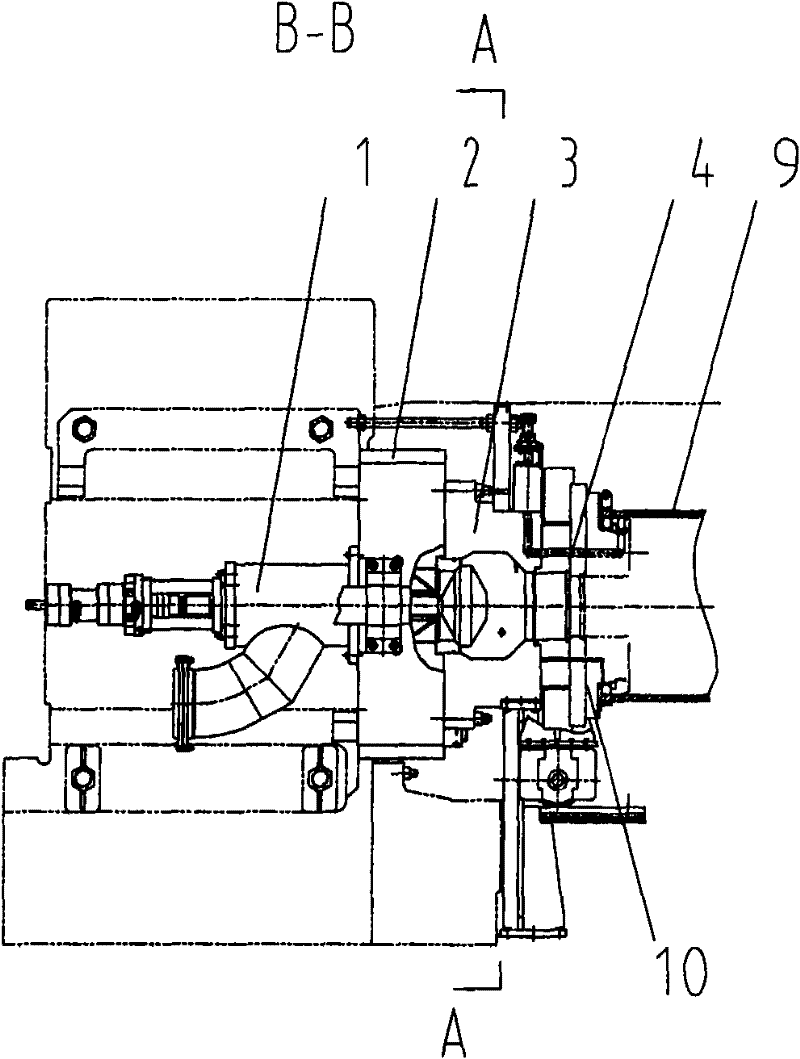

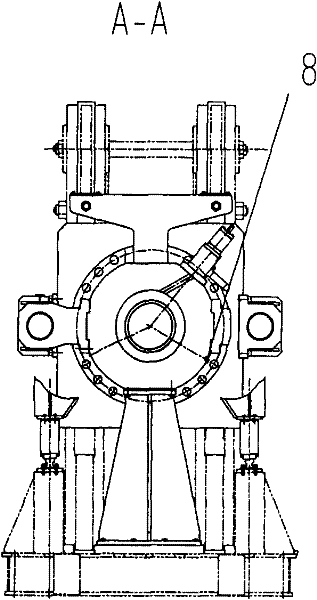

[0016] Such as figure 1 , 2 , shown in 3, a kind of water-filling pressurization device of steel pipe hydrostatic test, is made of water-filling valve 1, connection plate 2, water-filling booster head 3, end face seal 4, detachment oil cylinder 5, guide post 6, detachment Plate 7, seal 10 composition. The connecting plate 2 is fixed on the steel pipe hydraulic test equipment, the water filling valve 1 is fixed on the left side of the connecting plate 2, the water filling booster head 3 is fixed on the right side of the connecting plate 2, and the water filling valve 1 is fixed on the right side of the connecting plate 2. The valve 1 communicates with the water-filled booster head 3, and the two detachable oil cylinders 5 are respectively installed on both sides of the connecting plate 2, and the piston rod of the detachable oil cylinder 5 passes through the guide column 6 and the The tube removal plate 7 is connected, and an end face seal 4 is arranged between the end face o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap