A modified process for hydrocarbon recovery using in situ combustion

A hydrocarbon, oxidizing technology, used in earth-moving drilling, wellbore/well components, production fluids, etc., which can solve the problems of increasing the environment, "footprint impact, cost increase, etc."

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

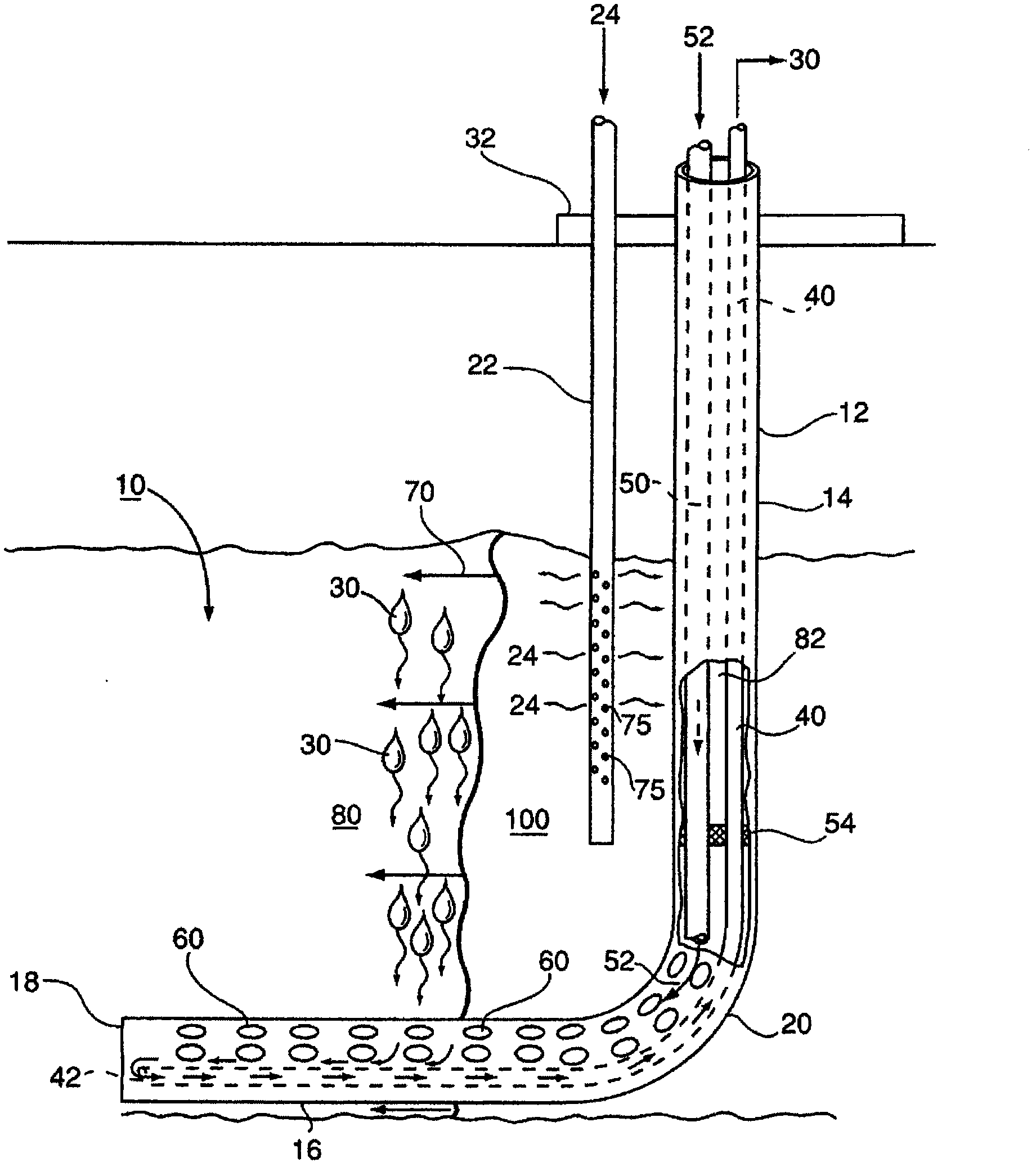

Embodiment Construction

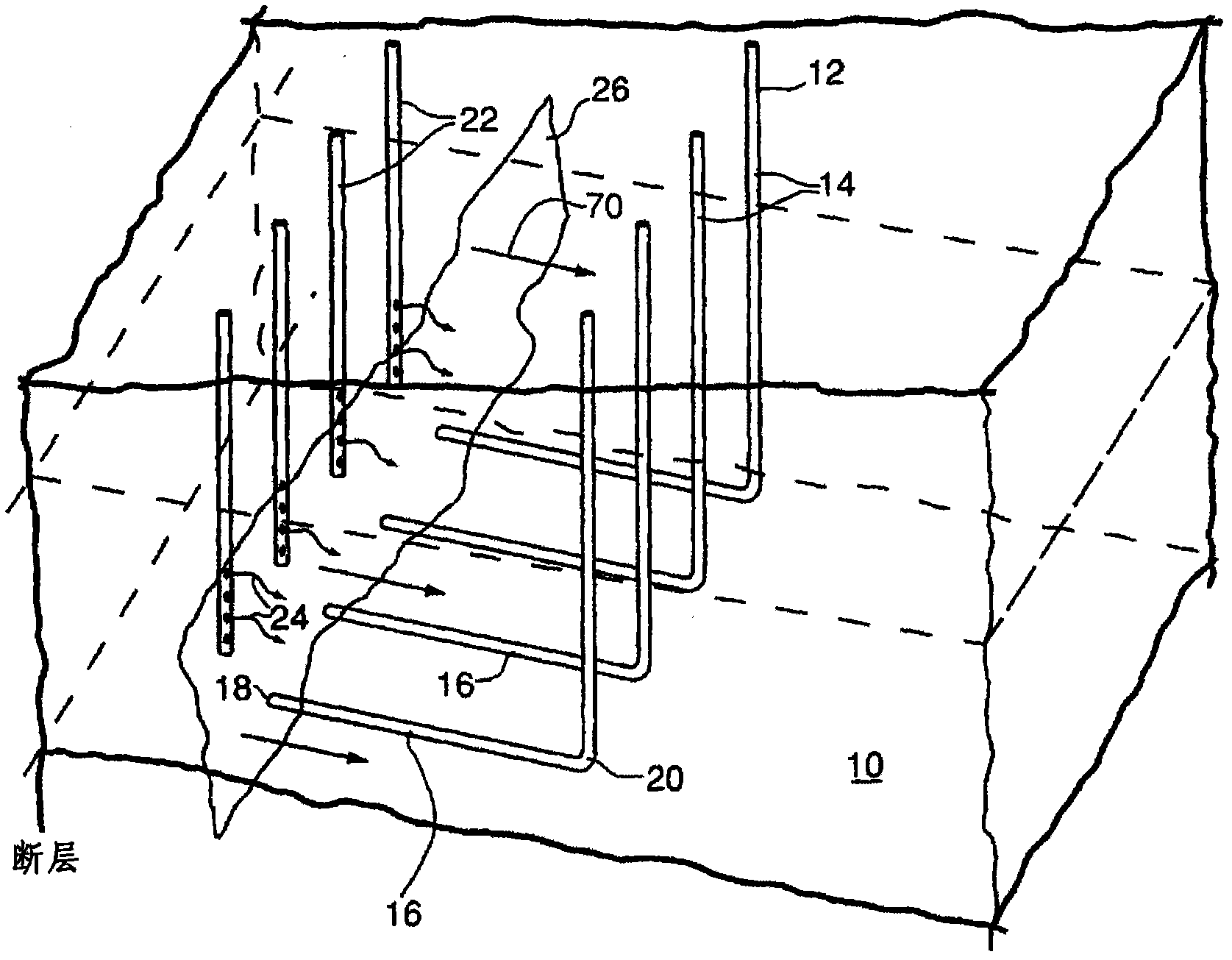

[0056] Figure 1A A translucent schematic diagram showing the layout of wells used in the prior art for in situ recovery of hydrocarbons from an underground hydrocarbon reservoir or formation 10 .

[0057] in particular, Figure 1A Schematically depicts a prior art method for on-site recovery of hydrocarbons disclosed in U.S. Patent No. 5,626,191, the prior art method comprising providing a series of production wells 12, each production well 12 comprising a substantially vertical section 14 and a substantially horizontal Leg 16 , substantially horizontal Leg 16 has a “toe” portion 18 and a “heel” portion 20 . Horizontal legs 16 of production wells 12 are located in the lower region of hydrocarbon formation 10 and are substantially porous to allow ingress of fluids. A series of injection wells 22 are provided that are located near the "toe" region and extend down into the formation 10 with perforations in the upper region of the oil-bearing reservoir.

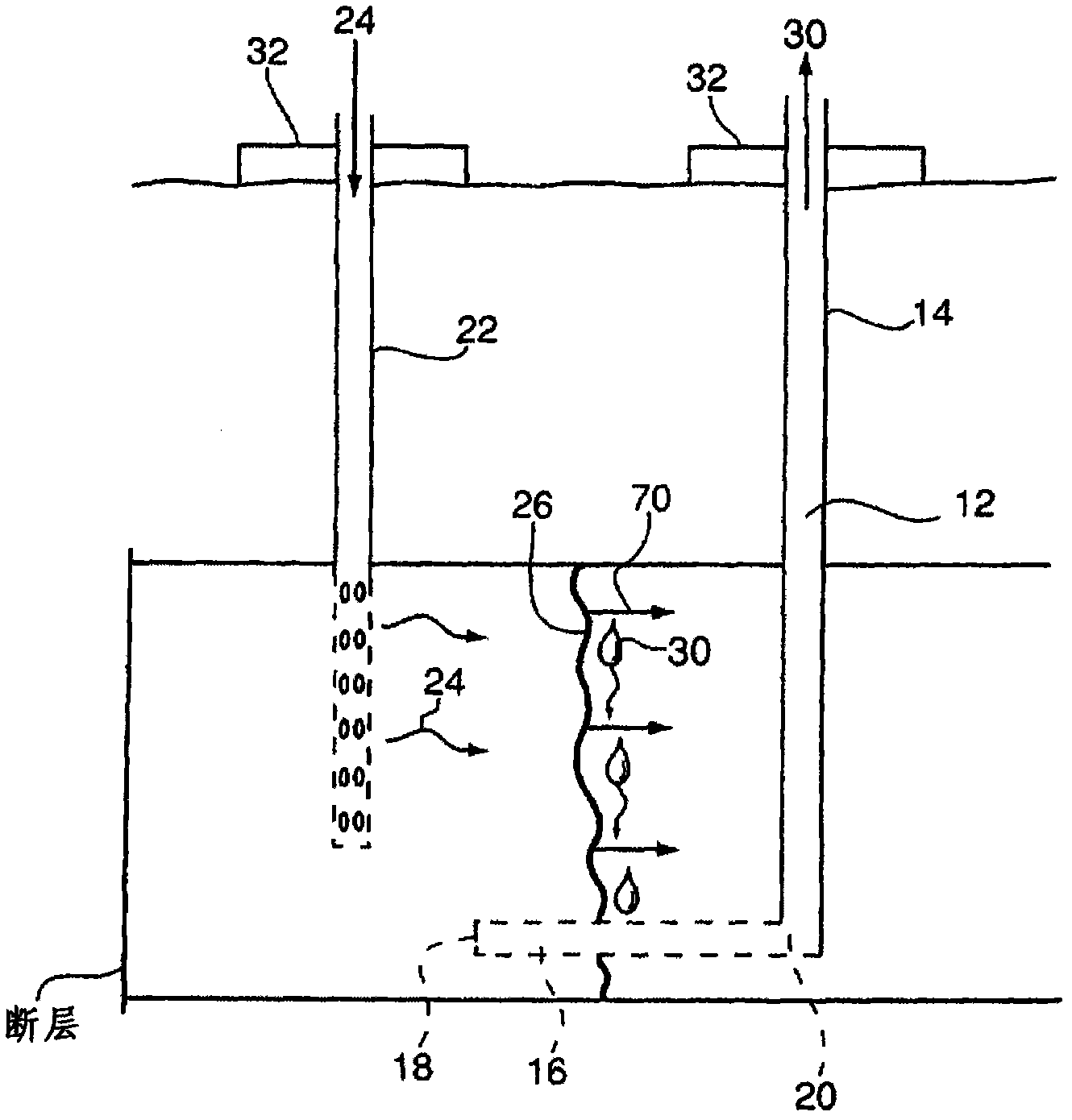

[0058] Figure 1B show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com