Equipment for eight assembly processes of junction box and assembly method

A junction box and equipment technology, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of inadequate installation, difficult processing, and uncompressed, so as to avoid wasting time, avoid human negligence, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

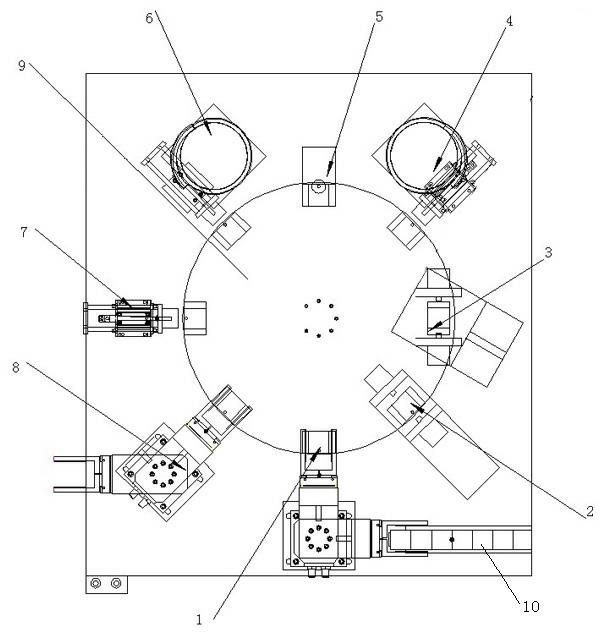

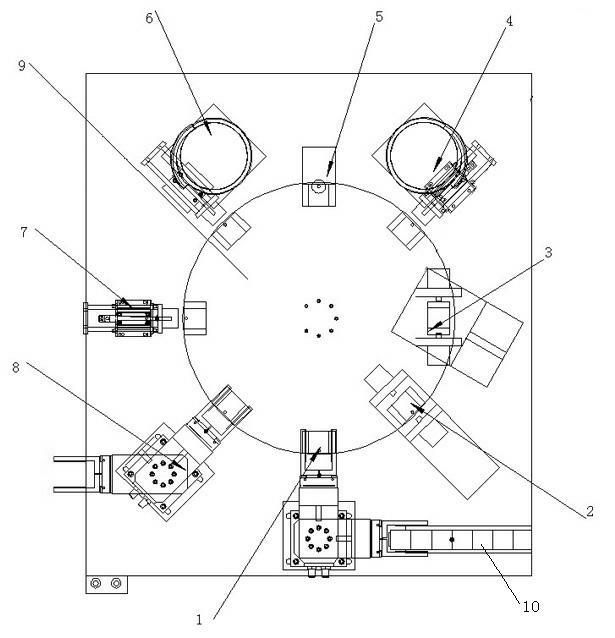

[0022] Such as figure 1 As shown, the equipment for assembling the junction box according to the present invention includes a workpiece loading and unloading device 1, a first punching device 2, a second punching device 3, a nut feeding device 4, a nut pressing device 5, a cover Feeding and pressing device 6, bolt feeding and pressing device 7, reclaiming device 8, cam divider 9, discharge assembly, cam divider 9 is disc-shaped and can rotate around a fixed axis, workpiece loading and unloading device 1, the first The first stamping device 2, the second stamping device 3, the nut feeding device 4, the nut pressing device 5, the cap feeding and pressing device 6, the bolt feeding and pressing device 7, and the retrieving device 8 are evenly distributed on the cam divider 9 Around, the front of the workpiece loading and unloading device 1 is provided with a discharge assembly 10, the second punching device 3 is connected with the lifting cylinder, and the above-mentioned compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com