Trousers hook clamp

The technology of a trouser hook and a jig is applied in the field of trouser hook and jig, which can solve the problems of increasing economic benefit, inaccurate position of trouser hook, inaccurate size and the like, and achieves the effects of increasing economic benefit, reducing waste and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

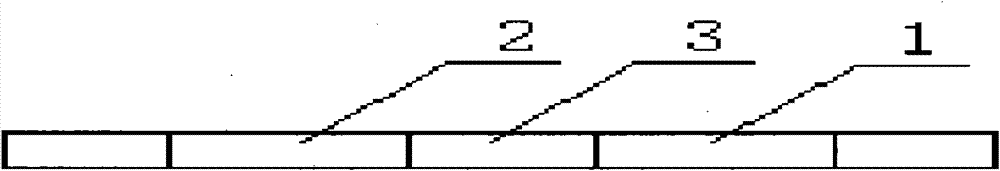

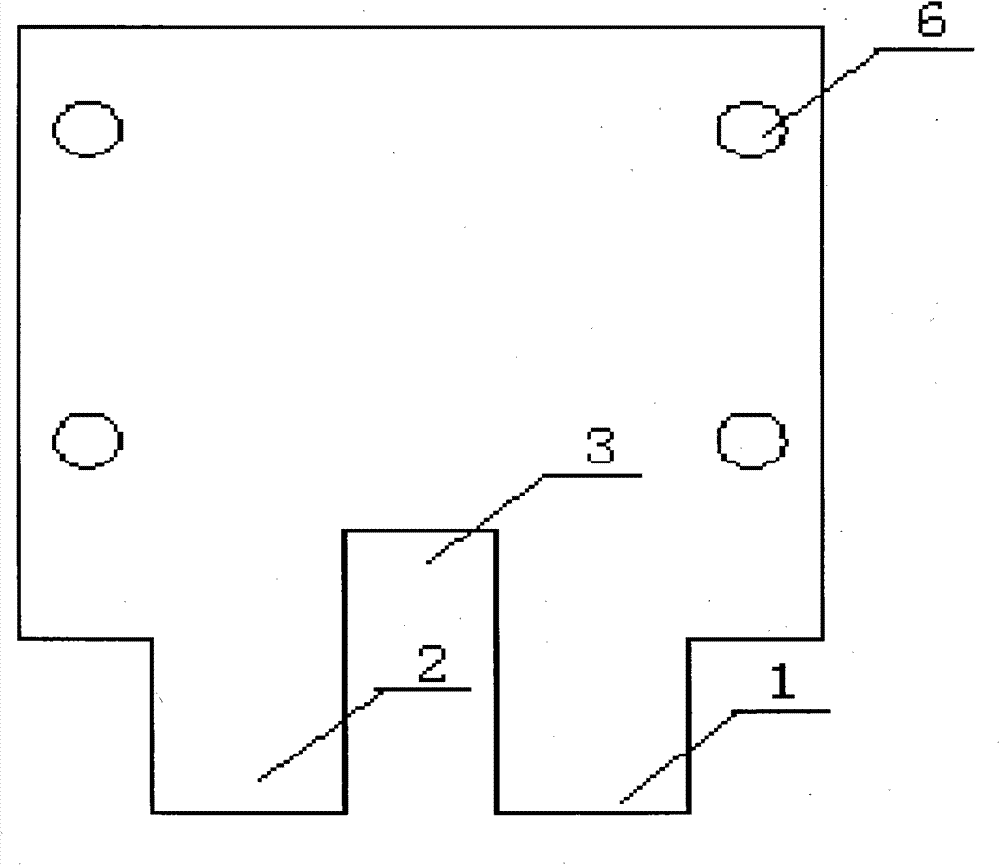

[0013] Such as figure 1 , figure 2 Shown a kind of trouser hook clamp, two protrusions (i.e. protrusion one 1, protrusion two 2) and a concave opening 3 are set at one end thereof, and the two protrusions (i.e. protrusion one 1, protrusion two 2) Protrusion 2) is symmetrically arranged on the top of the concave opening 3, and the outer edge width of the two protrusions (i.e. protrusion 1, protrusion 2 2) is the width of the inlaid groove at the waist of the trousers to be processed minus the thickness of the trouser hook fixture , the width between the outer edge of protrusion 1 and protrusion 2 is generally 2 to 6 cm. This width is convenient for inserting the trouser hook fixture into the inlay groove of the waist of the trousers to be processed, and the thickness of the trouser hook fixture is set to match the trouser hook The grooves have the same thickness, and the thickness of the trouser hook groove is generally 0.1 to 0.5 centimeters, which will not cause the trouser...

Embodiment 2

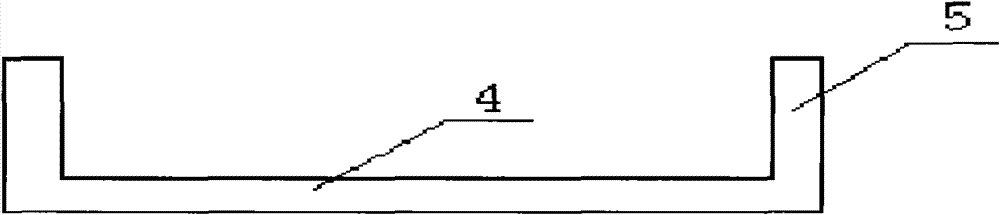

[0015] Such as image 3 , Figure 4 As shown, the trouser hook fixture adopts a groove structure, and the groove structure includes a groove bottom 4 and a groove edge 5. For the convenience of manufacturing the trouser hook fixture, the thickness of the trouser hook fixture is set to be consistent with the thickness of the groove edge 5. The thickness is consistent with the thickness of the trouser hook groove; two protrusions (i.e. protrusion one 1, protrusion two 2) and a concave opening 3 are set on the groove bottom 4 at an end of the groove structure, and the two Two protrusions (i.e. protrusion one 1, protrusion two 2) are symmetrically arranged on the top of the concave opening 3, and the outer edges of the two protrusions (i.e. protrusion one 1, protrusion two 2) are not provided with groove edges 2. The width of the outer edge of protrusion 1 and protrusion 2 is the width of the inlaid groove in the waist of the trousers to be processed minus the thickness of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com