Injection mold with movement core insert stopping mechanism

A technology for injection molds and male mold cores, which is applied in the field of injection molds and mold manufacturing. It can solve problems that affect the appearance of products, burrs, and PL surfaces that are not tightly closed, and achieve the effects of broad application prospects, improved appearance and yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

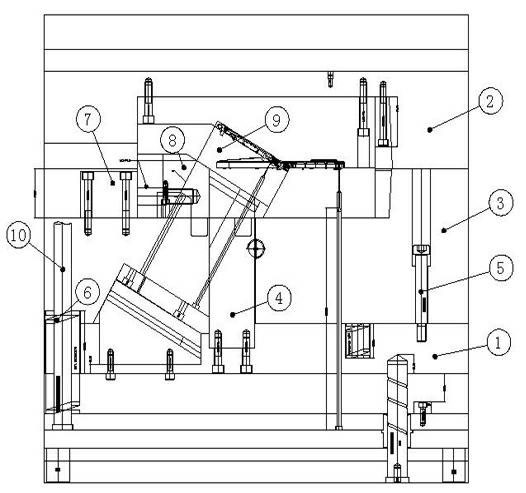

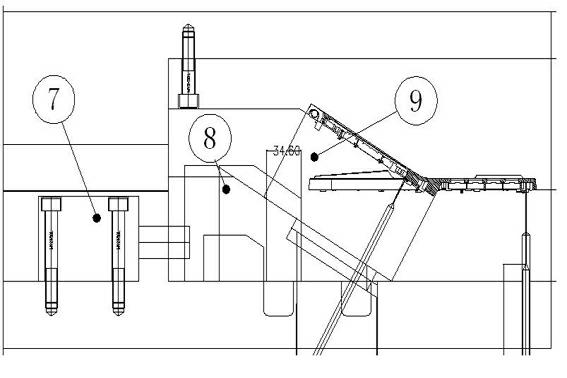

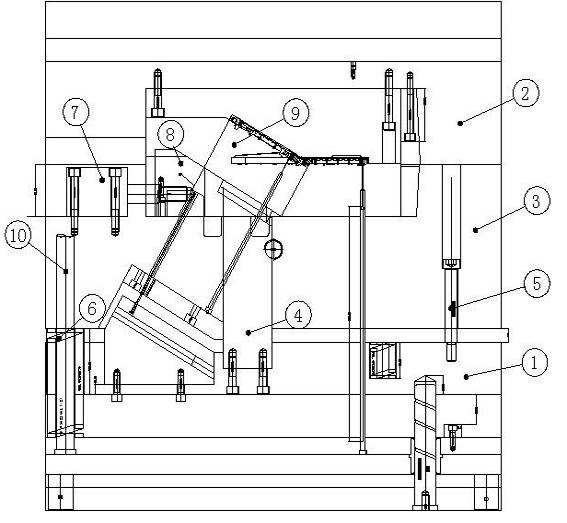

[0020] figure 1 It is the front view of the mold closed state of the present invention.

[0021] Such as figure 1 Shown: an injection mold with a movement male mold core stop mechanism, including a movable mold carrier plate 1, a movable mold plate 3, a fixed mold plate 2, a movable male mold core 9 and a bundle block 4. Among them, the fixed mold plate 2 and the movable mold plate 3 are opposite The movable male mold core 9 is set in the cavity formed by the cooperation of the fixed mold plate 2 and the movable mold plate 3. The movable mold bearing plate 1 is located at the lower part of the movable mold plate 3, and is connected with the movable mold plate 3 by equal height screws 5. The movable mold plate 3 The moving distance of is determined by the equal height screw 5, which plays a role of control, and the spring 6 arranged between the movable template 3 and the movable mold bearing plate 1 supports the movable template 3. In addition, the bundle block 4 is fixed on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com