Electric iron convenient for front and back ironing

An electric iron, a convenient technology, used in hand irons, washing devices, textiles and papermaking, etc., can solve the problems of hurting people, loose three screws, and inability to observe the bottom plate, etc., and achieves the effect of compact structure and convenient ironing operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

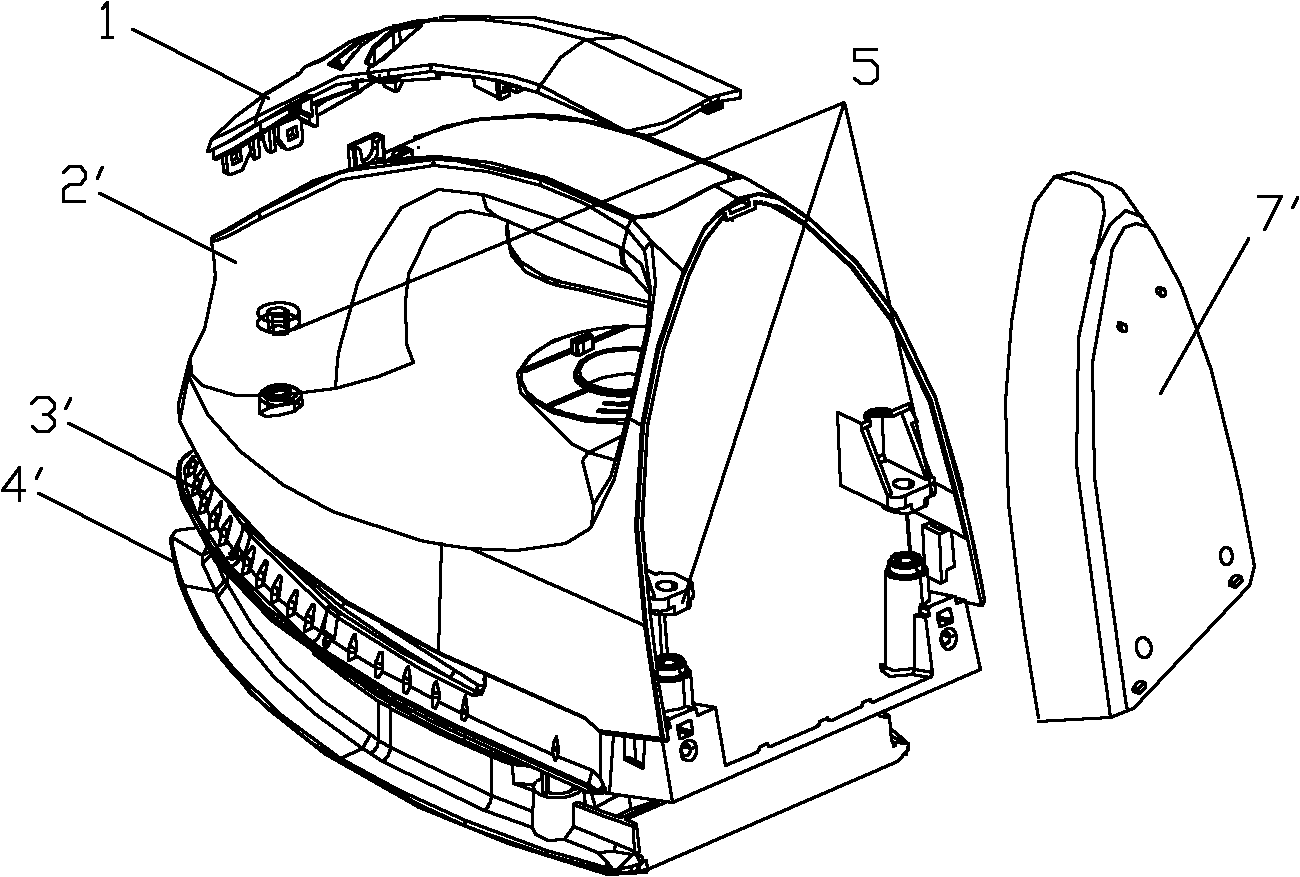

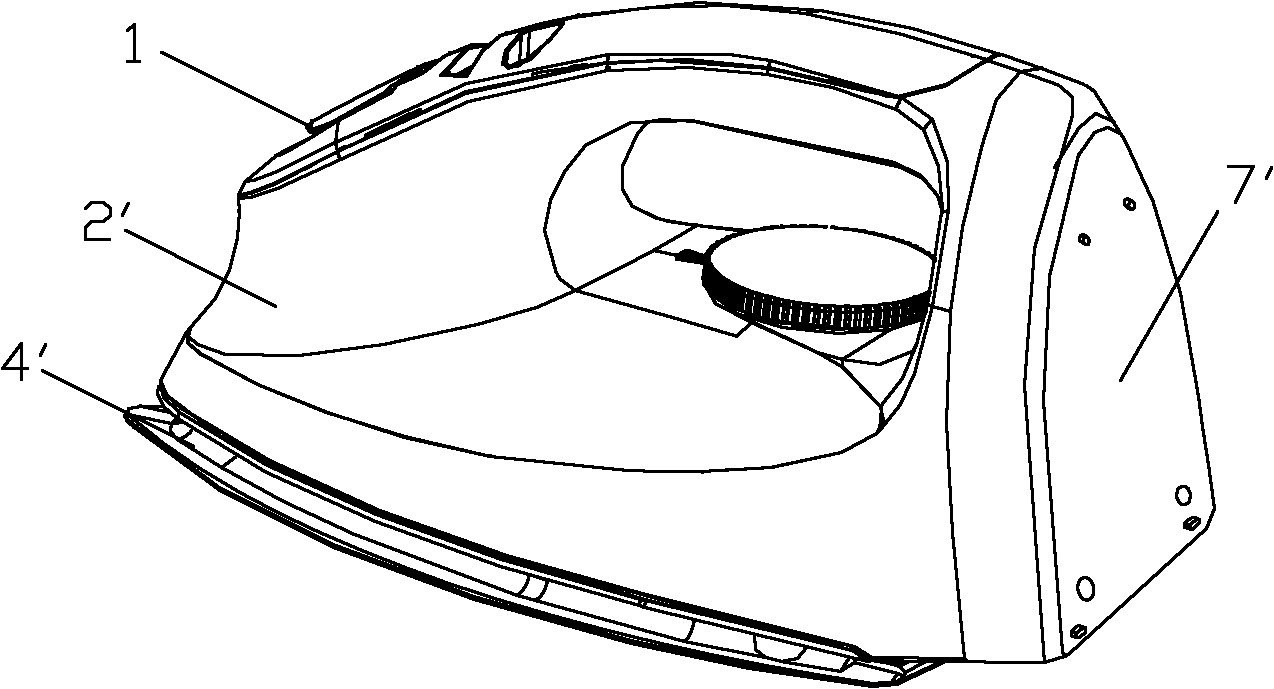

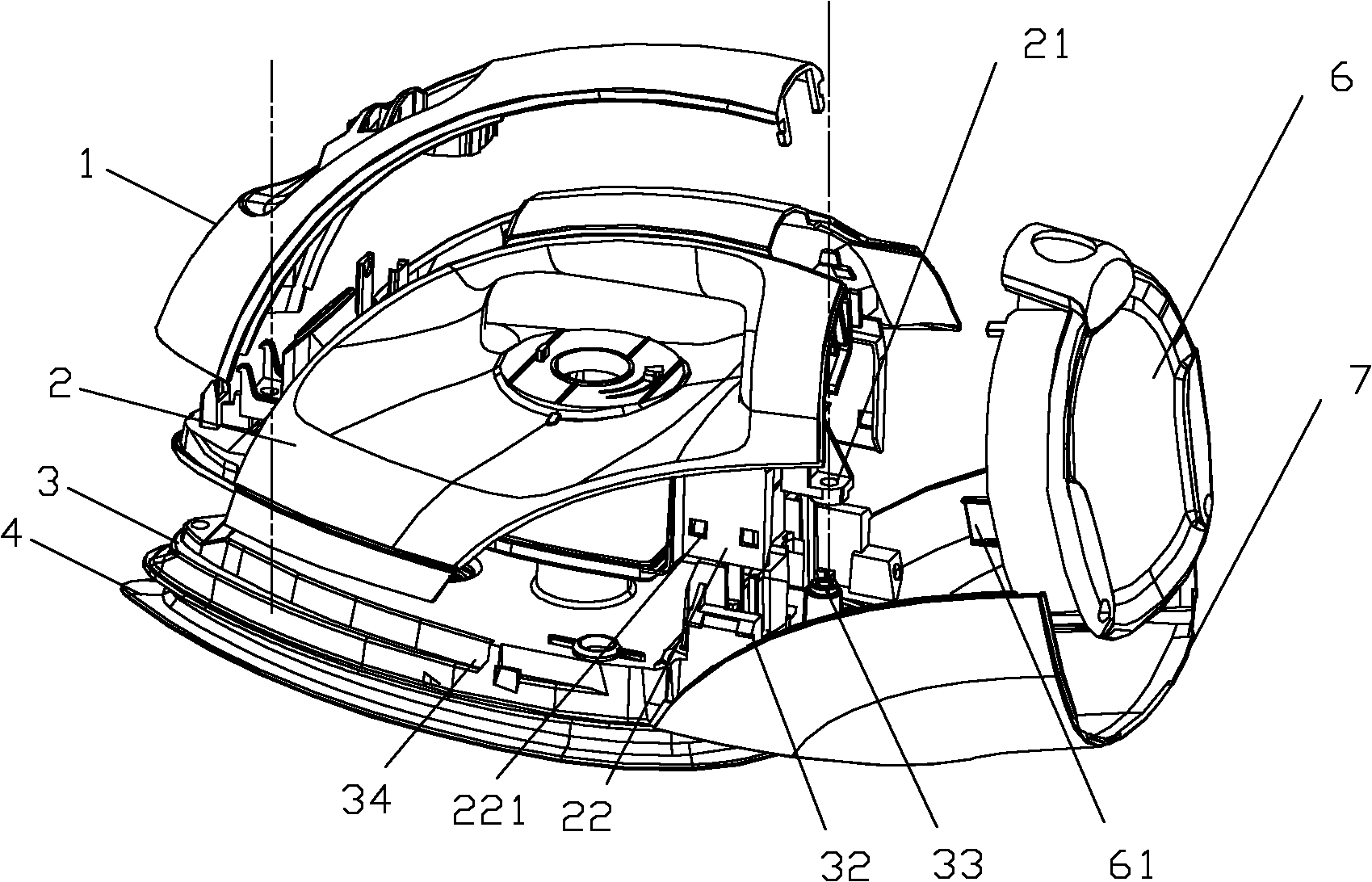

[0024] The present invention is a convenient electric iron for front and back ironing, which comprises a handle cover 1, a shell, a heat insulation board 3, a rear cover 6, a bottom plate 4 and the like.

[0025] Such as Figure 3-7 As shown, the casing includes a casing upper cover 2 and a casing lower cover 7, the two are butted together to form the casing of the electric iron. The front end of the heat shield 3 is provided with a first screw hole 31 , and the rear end protrudes upwards to form a fixing portion. The fixing portion includes an upwardly erected baffle 36 , an upwardly erected first engagement position 32 provided on both sides of the baffle 36 , and an upwardly erected second screw hole 33 provided at the middle of the rear side of the baffle 36 . The housing upper cover 2 is clamped and fixed with the first clamping positions 32 on both sides of the fixed part of the heat insulation board 3, and the housing upper cover 2 is at the positions corresponding to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com