A protective device on a welding torch

A protective device and welding torch technology, applied in auxiliary devices, welding equipment, fireproof coatings, etc., can solve problems affecting the health of operators, poor heat dissipation of protective masks, and inability to block welding spatter, etc., to achieve simple structure and reduce potential safety hazards , Improve the effect of comfort and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

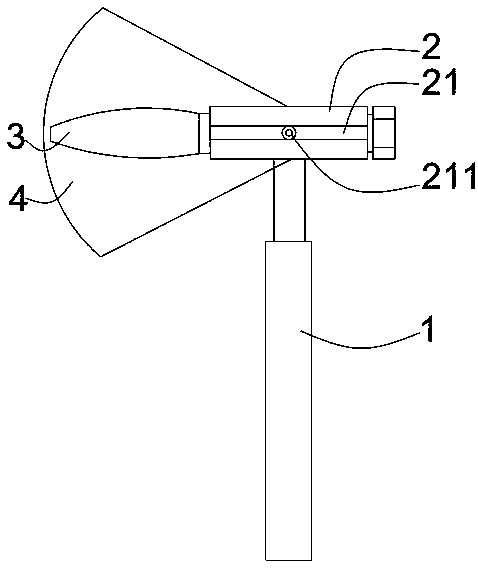

[0017] Such as figure 1 As shown, a protective device on a welding torch includes a handle 1, a welding torch tube 2, and a protective cover 4. The handle 1 is vertically fixedly connected to the welding torch tube 2, and one end of the welding torch tube 2 is connected with a welding torch nozzle 3, and the welding torch nozzle 3 is provided with a The protective cover 4 is connected with the welding torch tube 2 at the tail end of the protective cover 4 . When the welding torch operation starts to work, the protective cover 4 of the protective device on the welding torch can be directly covered above the welding position of the workpiece to be welded, and the operator does not need to use the protective mask when welding, so that the operator can release a hands, thereby improving the comfort and flexibility of welding operations; the protective device can block the sparks, welding shavings and strong light generated during welding operations, prevent leakage, protect the op...

Embodiment 2

[0025] The working principle of the protective device on the welding gun of the present invention is: the handle 1 of the device of the present invention is vertically fixedly connected with the welding gun tube 2, and one end of the welding gun tube 2 is connected with a welding gun nozzle 3, and a protective cover 4 is arranged outside the welding gun nozzle 3, and the tail end of the protective cover 4 The welding torch tube 2 is connected, and the side of the welding torch tube 2 is evenly distributed with chute 21, and the outer side of the chute 21 is provided with gaskets and nuts 211. The positions of the bolts correspond to the positions of the chute 21 one by one, so that the bolts just pass through the corresponding The chute 21 fixes the protective cover 4 in the welding torch tube 2. During use, the position of the protective cover 4 in the welding torch tube 2 can be adjusted according to the requirements of the weldment, and the protective cover 4 can slide on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com