Backlight module

A technology for a backlight module and a light source, applied in the structural field of the backlight module, can solve the problems of attenuating the light output efficiency of a light guide plate, failing to effectively receive the light output from the light source, and reducing the thickness of the light guide plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

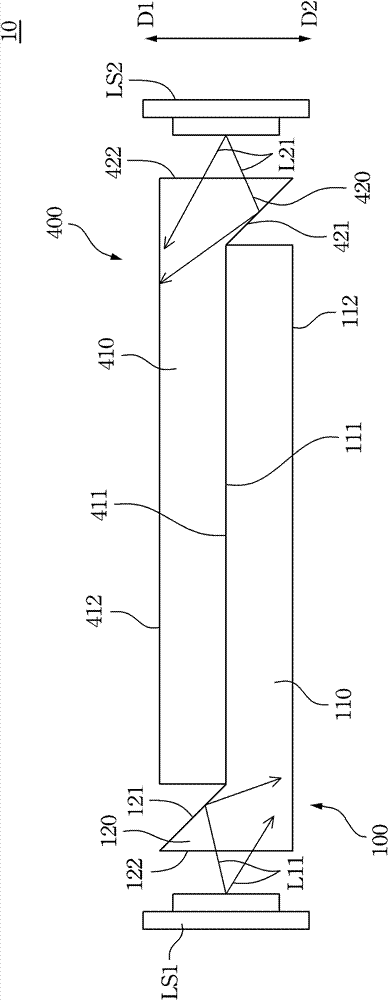

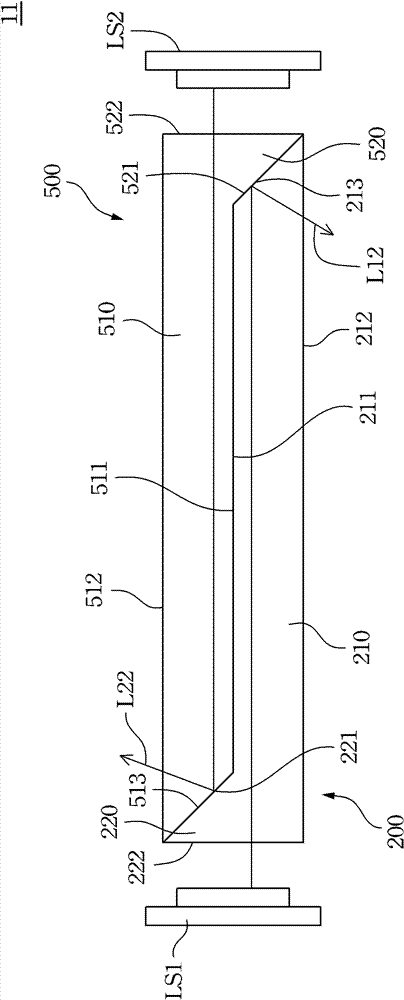

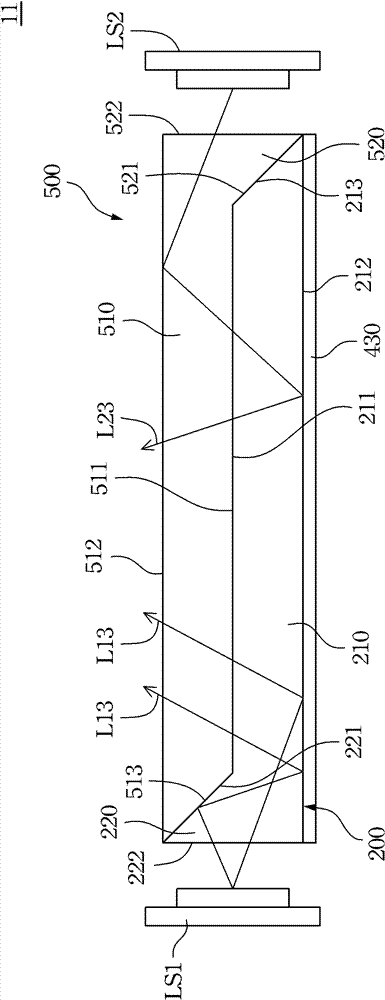

[0027] The present invention discloses a backlight module, which is used to increase the light-incident surface area of these light guide plates after lamination of two thinned light guide plates without increasing the thickness of the light guide plates themselves, so that The light incident surface of some light guide plates can effectively receive the light emitting surface with a large light emitting area.

[0028] The present invention discloses a backlight module for providing light sources in different directions, so as to provide bidirectional light sources for double-sided displays.

[0029] The present invention discloses a backlight module, which is used to match a plurality of light sources in different directions or / and colors, so as to uniformly mix light of expected colors.

[0030] One embodiment of the present invention provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com