Electret filter element and method for producing thereof

An electret and filter material technology, applied in separation methods, methods for reacting gaseous media with gaseous media, chemical instruments and methods, etc., can solve problems such as large equipment costs and increase costs, and achieve energy saving and strong charging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

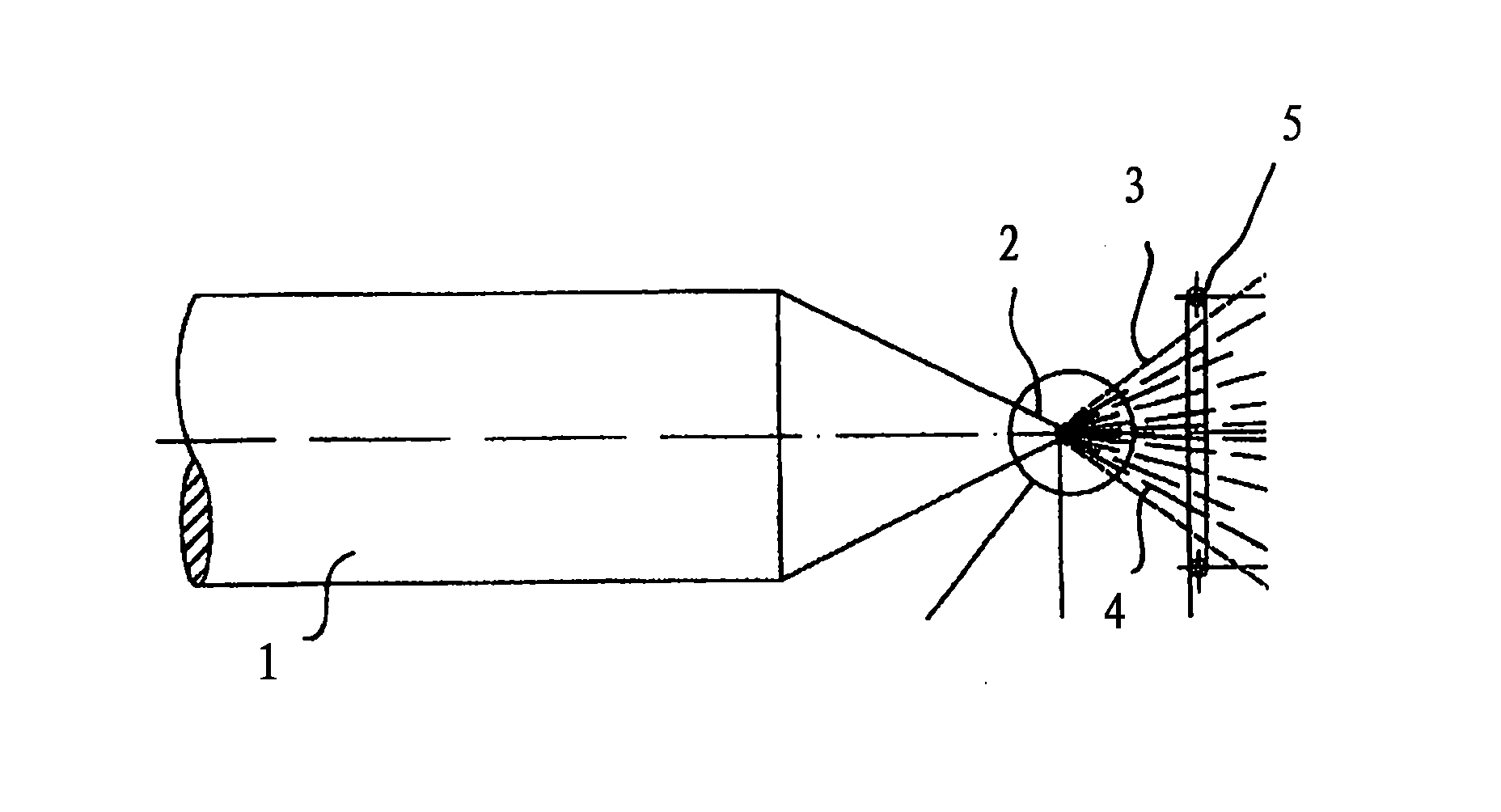

[0045] figure 1 A spray device 1 configured as a nozzle is shown in side view. A conical spray 3 is sprayed from the tip 2 of the spray device 1 , and the spray 3 is composed of individual droplets 4 . Droplet 4 is in a charged state. Charging is effected by an electric field formed between the disintegrated droplet 4 a and a ring electrode 5 .

[0046] In the spray 3, 60% or more of the charged droplets 4 held therein have charges of the same polarity. In the spray 3, the charge polarity of the droplets 4 held therein is independent of the droplet size.

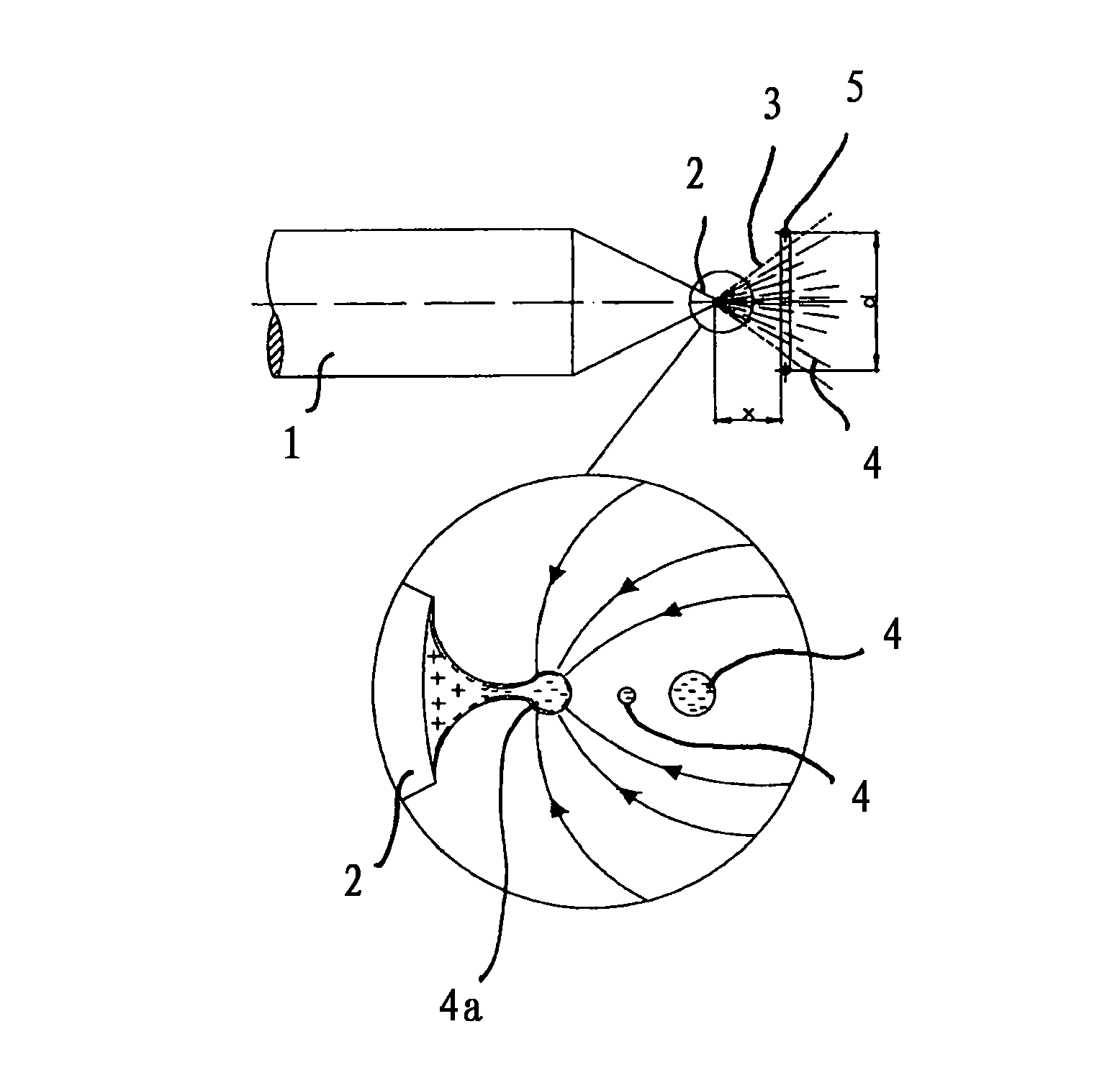

[0047] figure 2 Expressed in partial detail view (circular view) figure 1 The tip 2 of the spraying device 1 from which the droplets 4 are ejected and broken up. The droplet 4 is charged by an electric field (arrows represent its field lines) before it disintegrates, the charge being defined as negative in this schematic diagram.

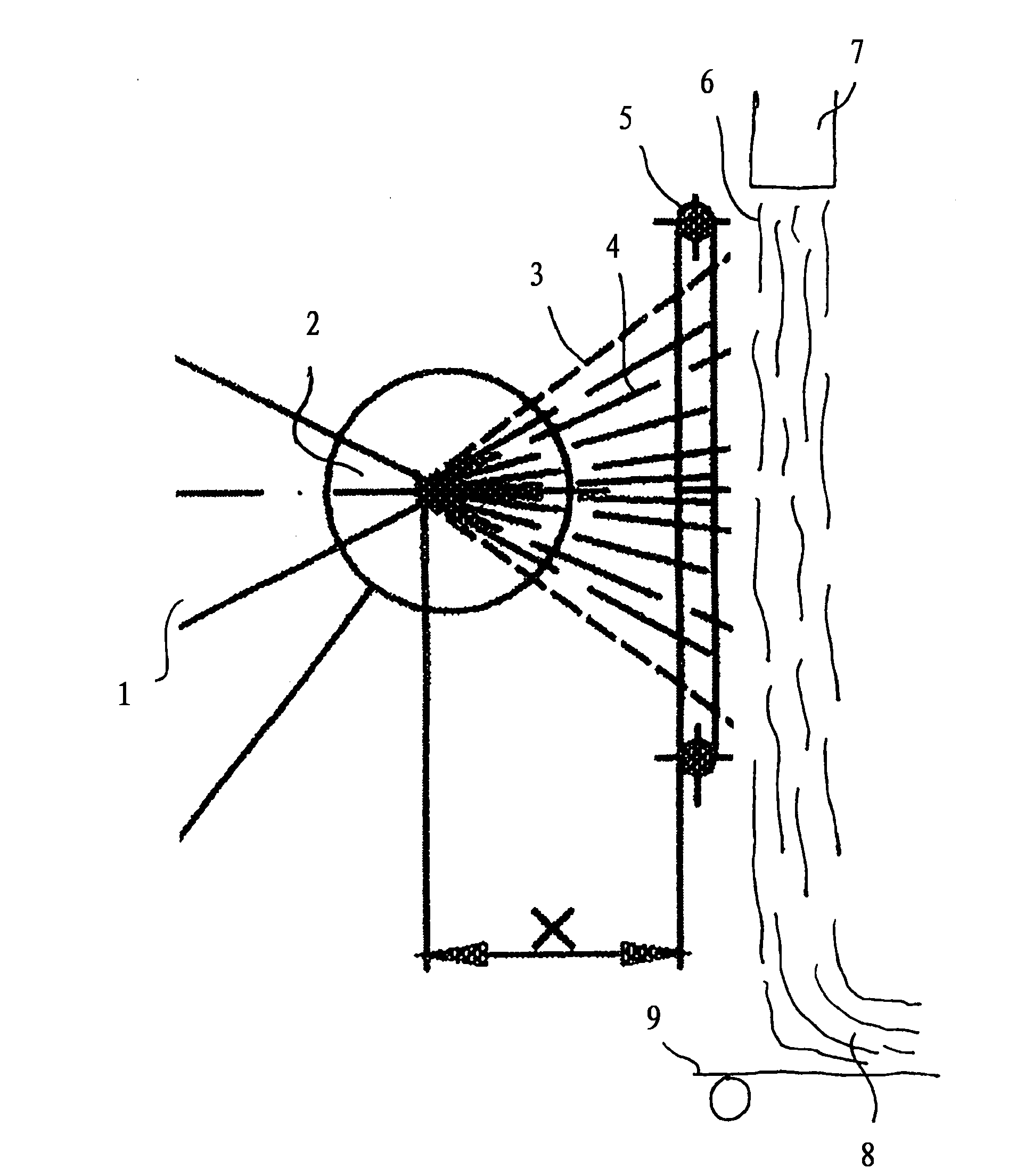

[0048] image 3 A spray device 1 is shown schematically, from which a tip 2 emits a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com