Opaque wet, see-through dry weather-resistive barriers and methods for making

A technology of weather resistance and barrier layer, applied in the direction of coating, transportation and packaging, thin material handling, etc., can solve the problems of over-coating, opaque coating, under-coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

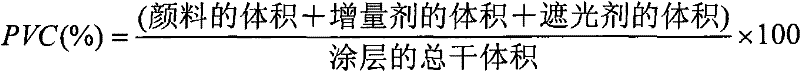

[0073] EXAMPLES: The following examples illustrate the invention.

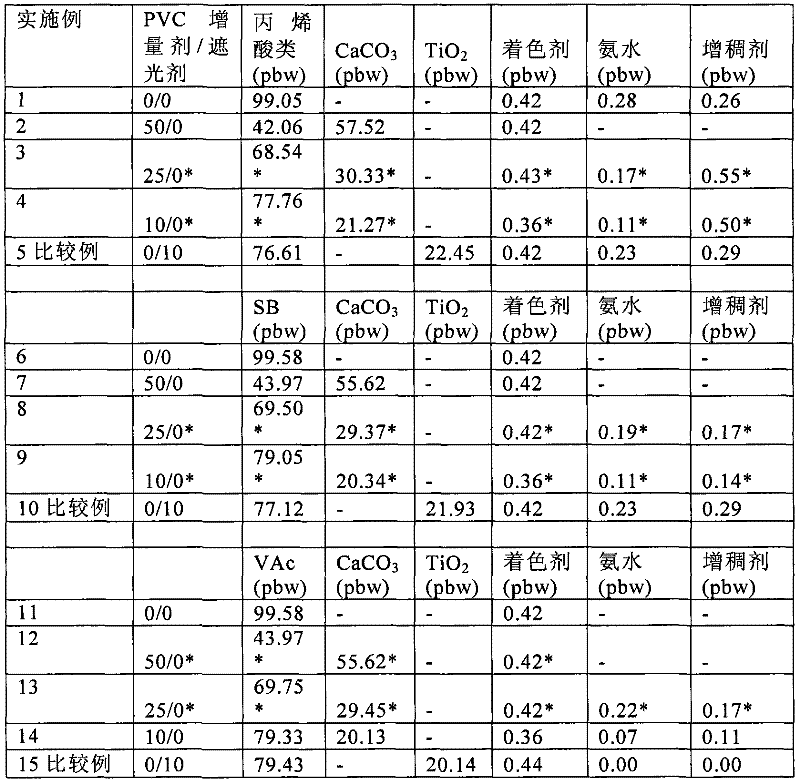

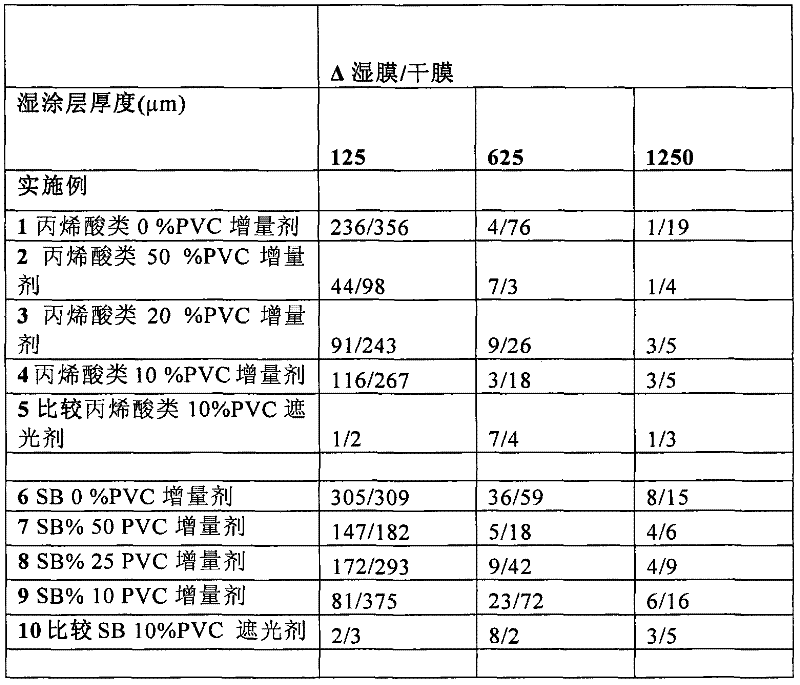

[0074] In Examples 1-15 below, each of the three emulsion polymers was formulated as shown in Table 1, and five coatings were prepared using calcium carbonate with the indicated % PVC as the extender. A 50% PVC coating was first formulated and then diluted to the indicated formulation with the indicated emulsion polymer to produce a formulation of 25% PVC and 10% PVC extender. One paint formulated from each of the three emulsion polymers contained 10% PVC titanium dioxide (opacifier) and one paint formulated from each of the three emulsion polymers contained no pigments or extenders agent, 0% PVC.

[0075] The materials used in the examples are as follows:

[0076] Acrylic: butyl acrylate / methyl methacrylate emulsion copolymer, 55% (w / w) solids, Tg (glass transition temperature) -40°C, weight average particle size 350nm;

[0077] SB styrene / butadiene emulsion copolymer, 51% (w / w) solids, Tg is -26°C, weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com