Method for using ultraviolet light to irradiate OTS-modified ITO glass substrate

A technology of glass substrate and ultraviolet light, which is applied in the production field of ITO glass substrate, can solve the problems of uneven functionalization, incomplete cleaning, easy damage to the substrate surface deposition environment, etc., and achieve uniform functionalization, less defects and strong bonding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

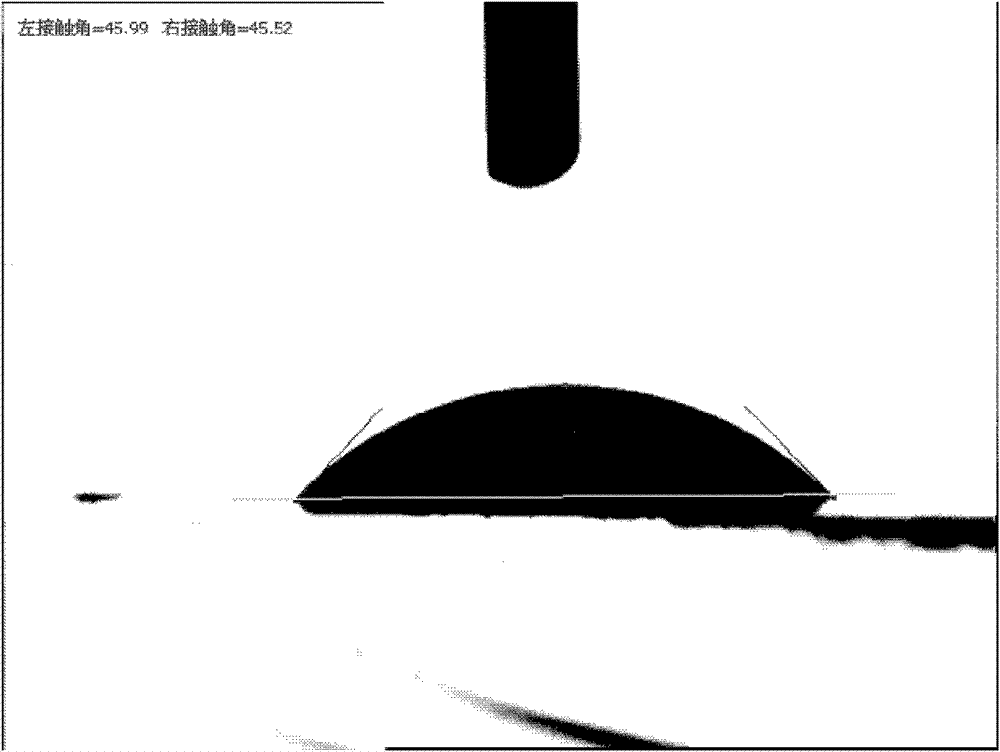

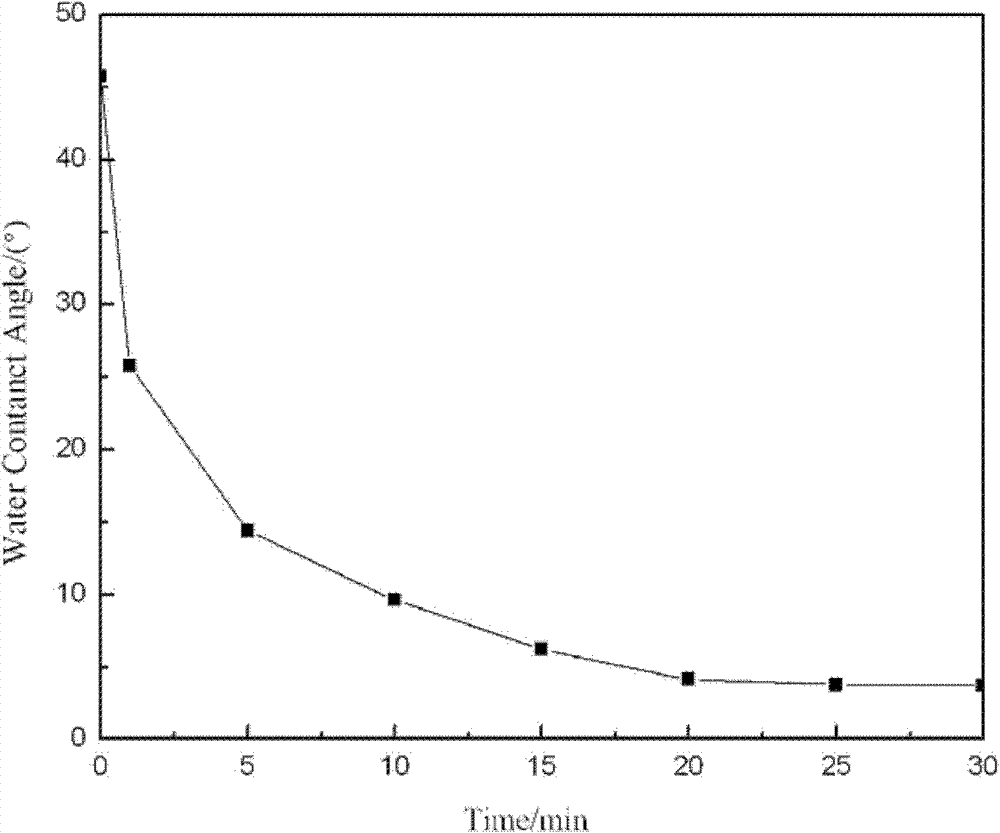

Embodiment 1

[0046]1) Cut the ITO glass substrate with a glass knife, the size is 1cm×2.5cm, put the cut ITO glass substrate into the commercially available detergent solution and ultrasonically vibrate for 10min to initially remove the impurities and organic matter on the surface, Next, take the ITO glass substrate out of the detergent solution and rinse it with deionized water; then put it into the acetone solution, and perform ultrasonic cleaning for 10 minutes again to further remove the stubborn organic components on the surface, then take the ITO glass substrate out again and use Rinse it with deionized water; finally put it into an ethanol solution for a third 10min ultrasonic cleaning, take it out and rinse it with deionized water to further improve the cleanliness of the substrate surface. Finally, the surface of the cleaned ITO glass substrate is blown dry with nitrogen gas, that is, the ITO glass substrate after cleaning in the previous stage.

[0047] Put the cleaned ITO glass ...

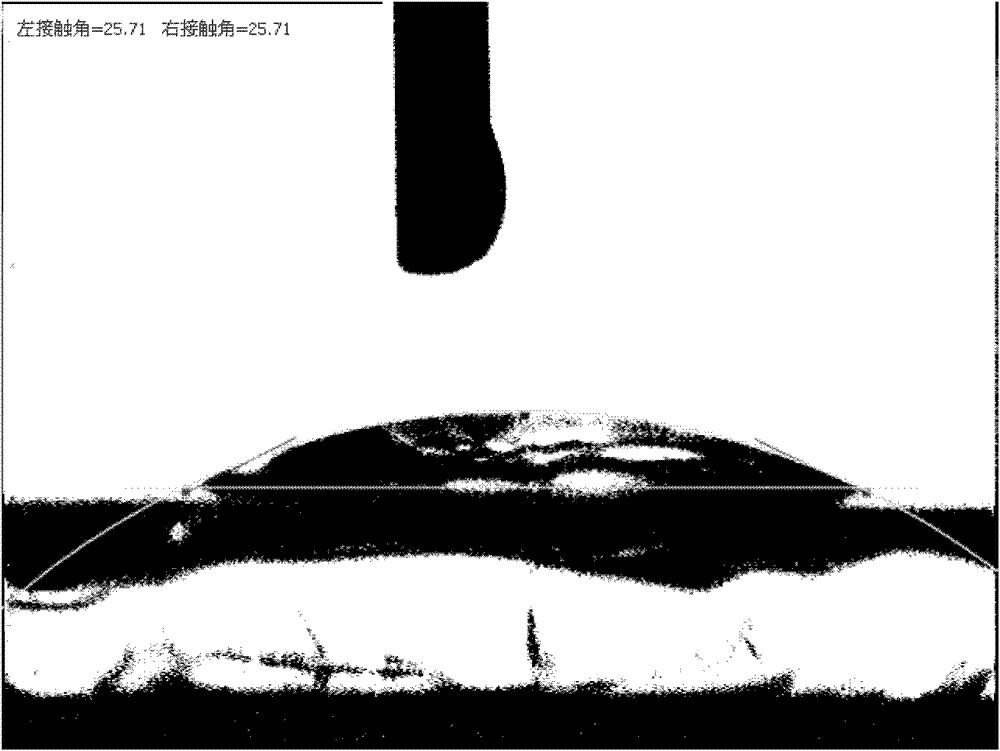

Embodiment 2

[0065] 1) Cut the ITO glass substrate with a glass knife, the size is 1cm×2.5cm, first put the cut ITO glass substrate into the detergent solution and oscillate ultrasonically for 10 minutes to remove the impurities and organic matter on the surface initially, then Take the ITO glass substrate out of the detergent solution and rinse it with deionized water; then put it into the acetone solution and perform ultrasonic cleaning for 10 minutes again to further remove the stubborn organic components on the surface, then take the ITO glass substrate out again and use deionized Rinse it with water; finally put it into an ethanol solution for a third 10min ultrasonic cleaning, and rinse it with deionized water after taking it out to further improve the cleanliness of the substrate surface. Finally, the surface of the cleaned ITO glass substrate is blown dry with nitrogen gas, that is, the ITO glass substrate after cleaning in the previous stage.

[0066] Put the cleaned ITO glass sub...

Embodiment 3

[0070]1) Cut the ITO glass substrate with a glass knife, the size is 1cm×2.5cm, first put the cut ITO glass substrate into the detergent solution and oscillate ultrasonically for 10 minutes to remove the impurities and organic matter on the surface initially, then Take the ITO glass substrate out of the detergent solution and rinse it with deionized water; then put it into the acetone solution and perform ultrasonic cleaning for 10 minutes again to further remove the stubborn organic components on the surface, then take the ITO glass substrate out again and use deionized Rinse it with water; finally put it into an ethanol solution for a third 10min ultrasonic cleaning, and rinse it with deionized water after taking it out to further improve the cleanliness of the substrate surface. Finally, the surface of the cleaned ITO glass substrate is blown dry with nitrogen gas, that is, the ITO glass substrate after cleaning in the previous stage.

[0071] Put the cleaned ITO glass subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com