Movement parameter calibration mechanism

A technology for calibrating mechanisms and parameters, applied in measuring devices, instruments, surveying and mapping, and navigation, etc., can solve problems such as no limitations, and achieve the effect of optimal design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

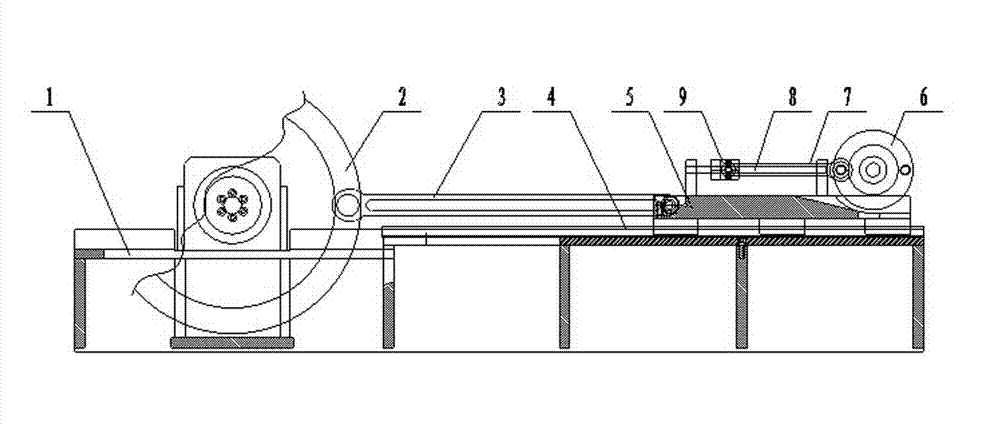

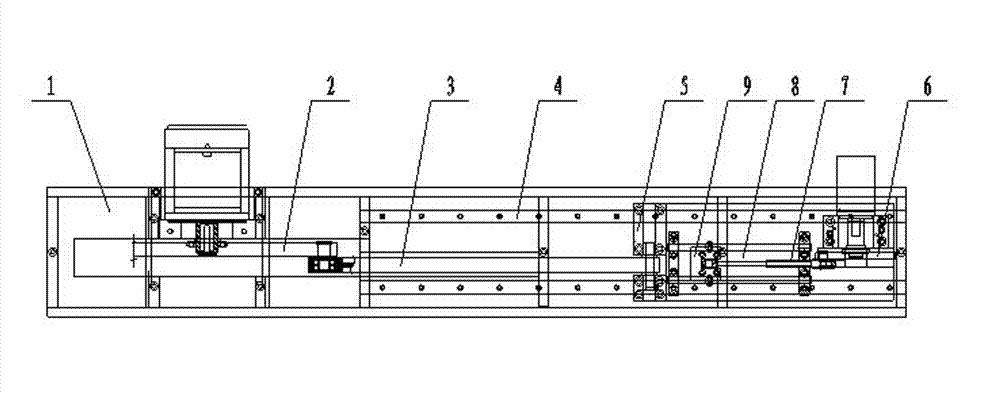

[0010] The motion parameter calibration mechanism includes a large crank connecting rod mechanism, a small crank connecting rod mechanism, and a frame 1; the large crank connecting rod mechanism includes a large motor, a large wheel disc 2 with an interference fit with the large motor, and a gap between the large wheel disc 2 Coordinated large connecting rod 3 and large guide rail pair; the large guide rail pair is composed of a large guide rail 4 and a large carriage 5; wherein, the large guide rail 4 is fixed to the frame 1, and the large carriage 5 is twisted with the large connecting rod 3; the small The crank-link mechanism includes a small motor, a small wheel disc 6 with an interference fit with the small motor, a small connecting rod 7 with a clearance fit with the small wheel disc 6, and a small guide rail pair; the small guide rail pair consists of a small guide rail 8 and a small carriage 9 Composition; wherein, the small guide rail 8 is fixed to the large carriage 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com