Calibration and compensation method for mounting errors between triaxial vector sensor and mounting carrier

An installation error and sensor technology, which is applied in the field of calibration and compensation of installation error between a three-axis vector sensor and an installation carrier, and can solve problems such as the measurement result error of the three-axis vector sensor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

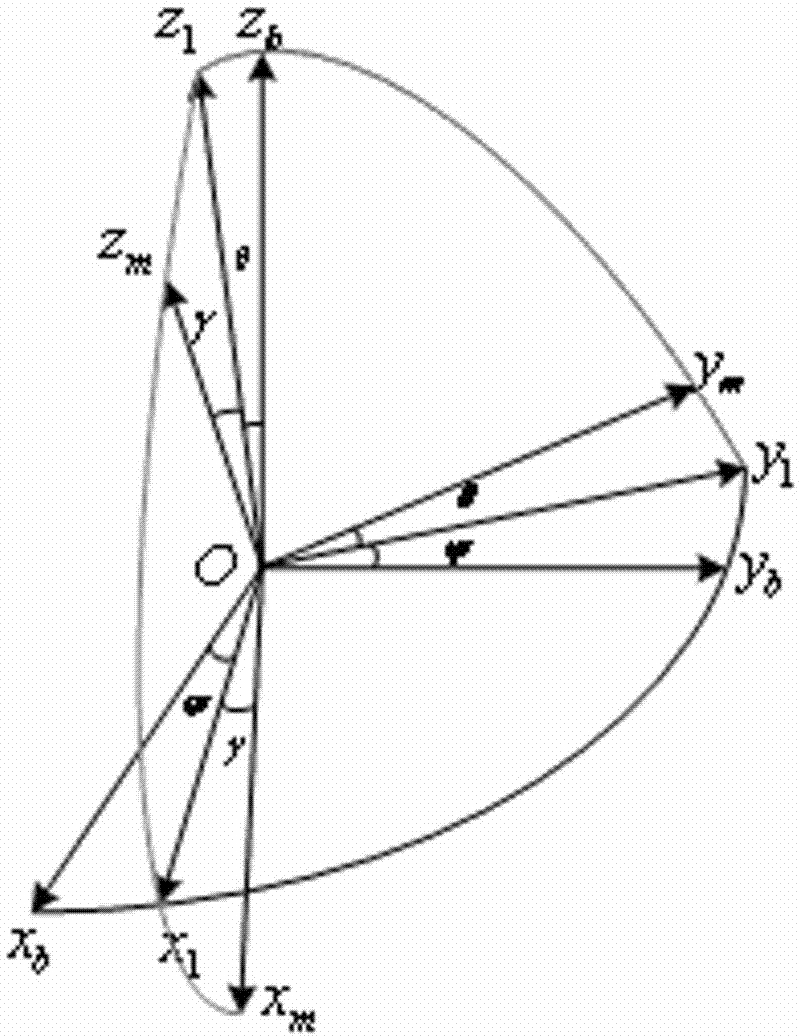

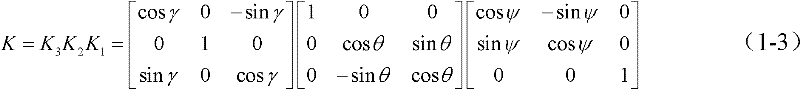

[0053] The method of the present invention will be further described below by taking the installation angle error between the calibration triaxial vector accelerometer and the installation carrier as an example:

[0054] Suppose the theoretical value of the gravitational acceleration measured by the three-axis vector accelerometer in the carrier coordinate system is However, the output value of the measured gravitational acceleration of the three-axis vector accelerometer in its own measurement coordinate system is Then there is the measured gravitational acceleration output value G m , theoretical value G b The relational formula:

[0055] G m =KG b (1-1)

[0056] i.e. G b = K -1 G m (1-2)

[0057] Among them, K is the installation error coefficient matrix, K -1 is the inverse matrix of the correction coefficient matrix-installation error coefficient matrix K;

[0058] The installation error coefficient matrix K is obtained by the following method:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com