Error correcting method of scraping plate

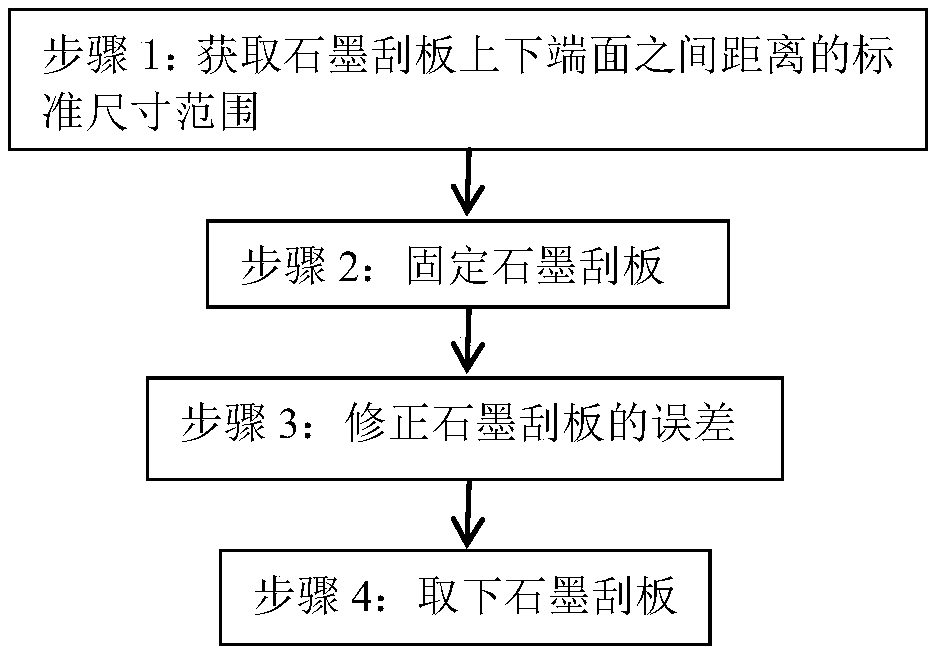

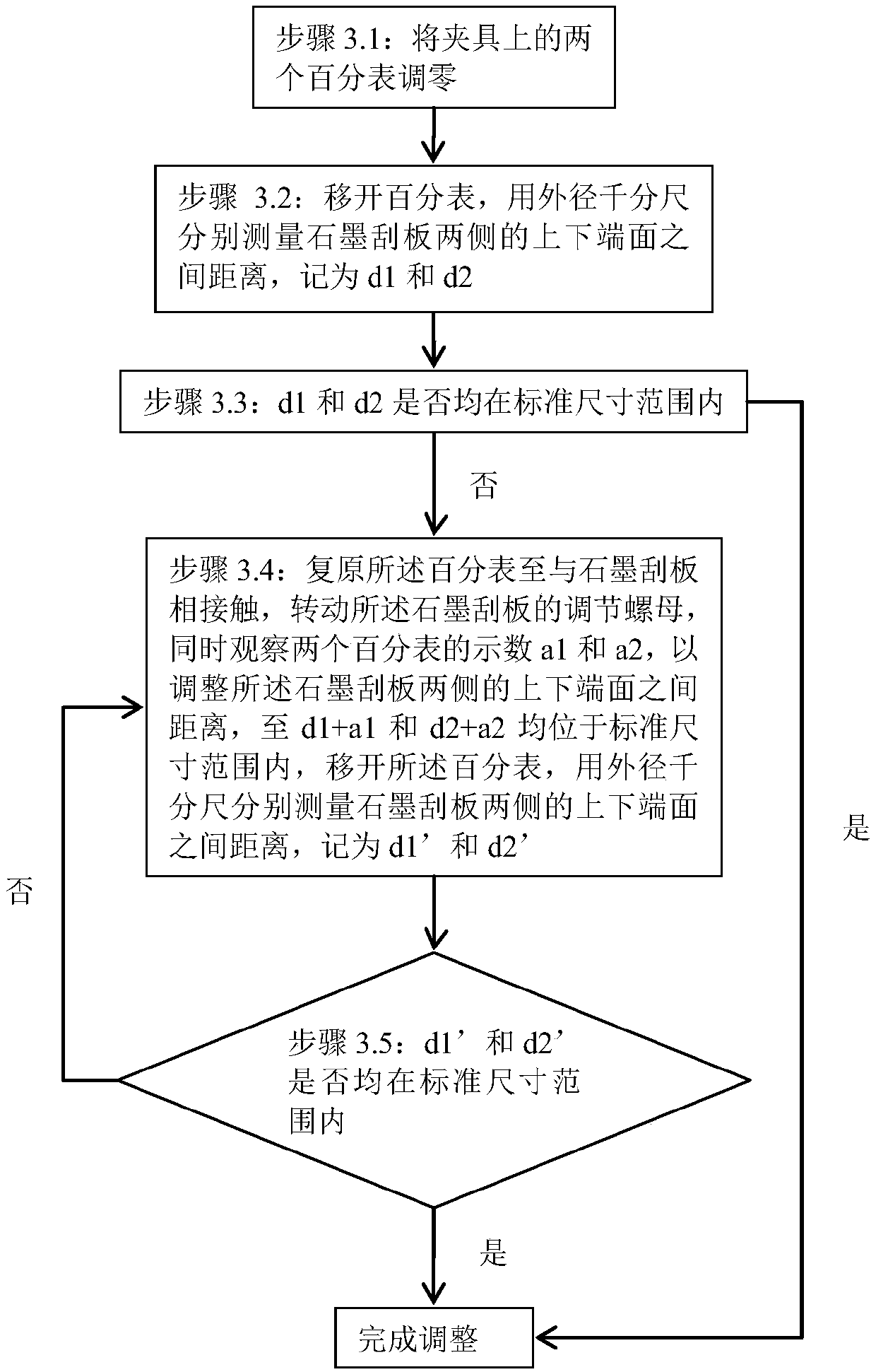

An error correction and scraper technology, used in manufacturing tools, mechanical gap measurement, workpiece clamping devices, etc., can solve problems such as low efficiency and complicated operation, save time, simplify scraper correction process, and improve scraper The effect of correcting the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

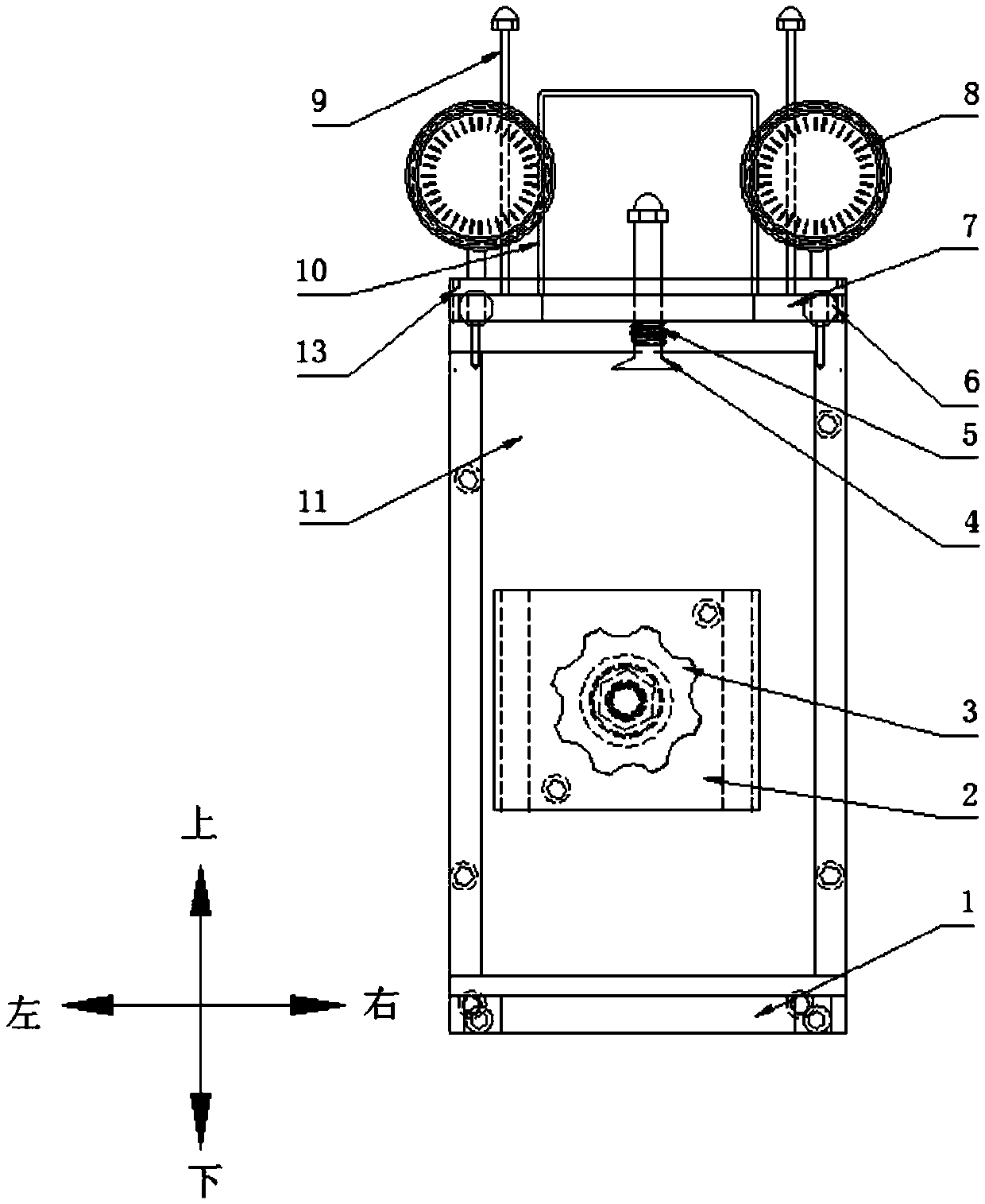

[0029] 1) Graphite scraper

[0030] Such as Figure 7 Shown is the graphite scraper 16 in the prior art flowmeter, the upper scraper 161 and the lower scraper 166 are connected by a left connecting rod 1652 and a right connecting rod 1651, and both ends of each connecting rod are horizontally fixed with U-shaped pins 162 and a compression spring 163 is sleeved between the U-shaped pin 162 and the upper scraper 161 or the lower scraper 166 . When the graphite scraper 16 works in the flowmeter, the upper end surface of the upper scraper 161 and the lower end surface of the lower scraper 166 are close to the inner wall of the flowmeter cavity. The upper scraper 161 and the lower scraper 166 are made of graphite material, which will be worn during operation, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com