Matrix type touch panel and designing method thereof

A touch panel and design method technology, which is applied in computing, instrumentation, electrical digital data processing, etc., can solve the problems of touch point position deviation, affecting the linearity of the touch panel, and limited wiring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

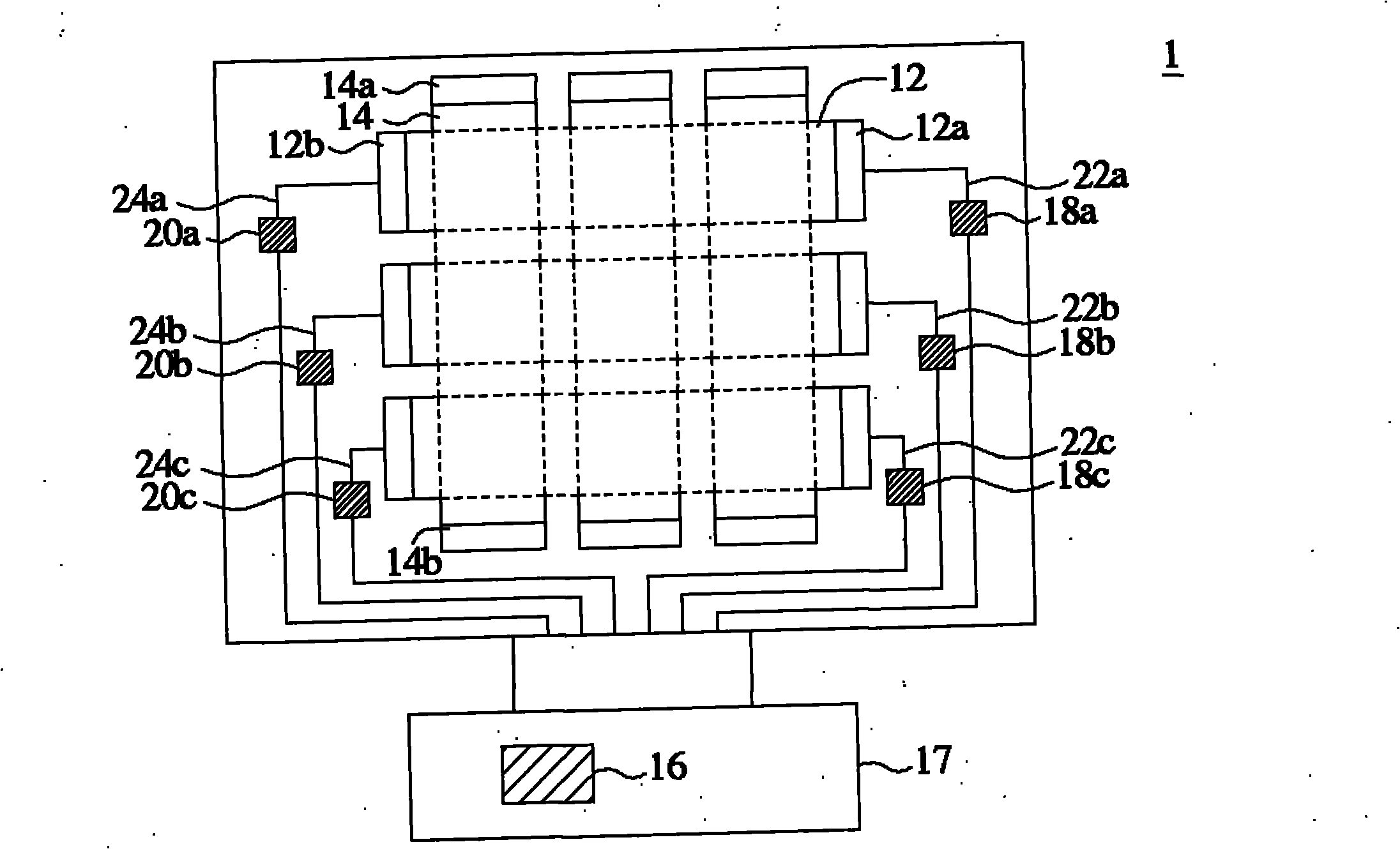

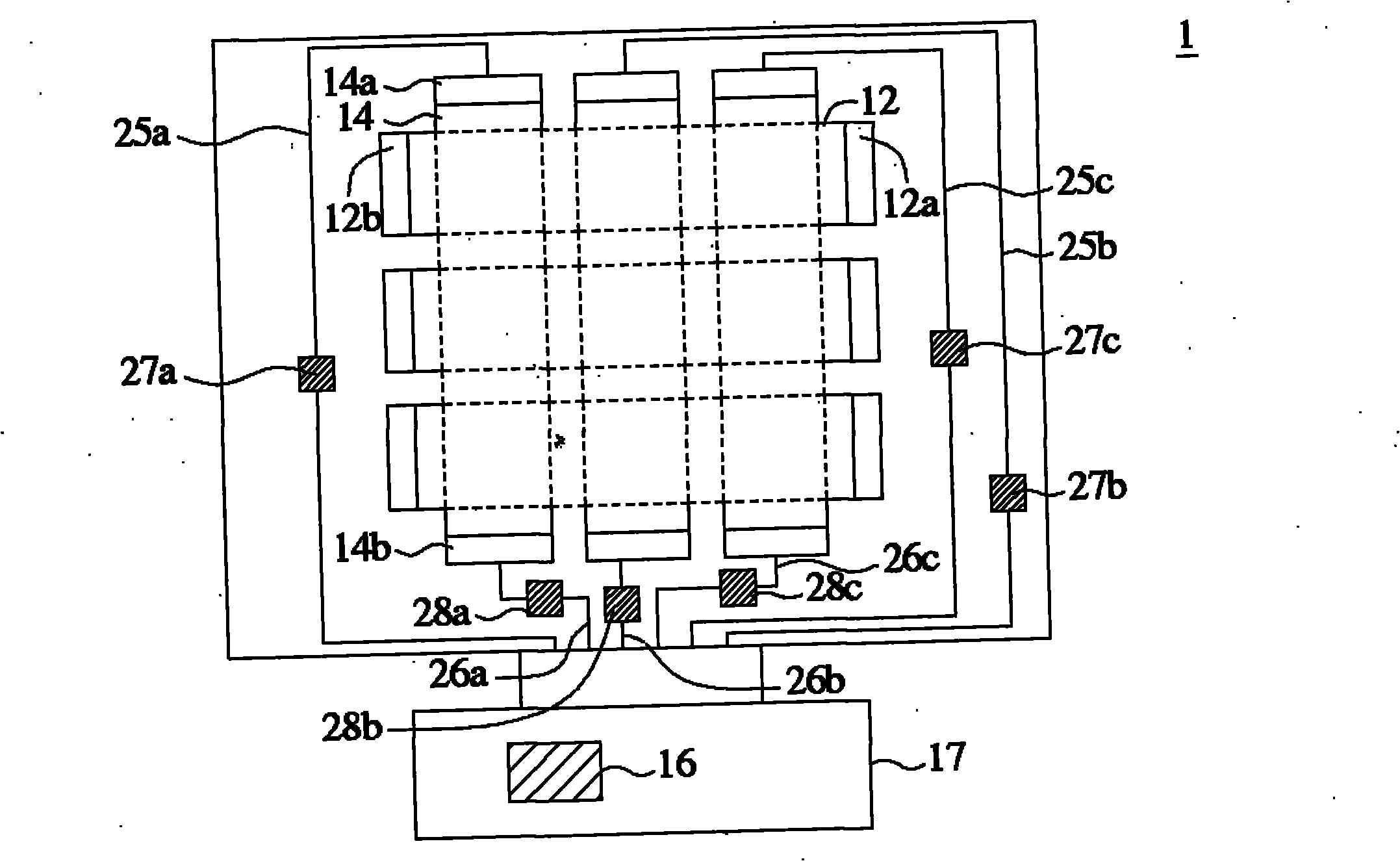

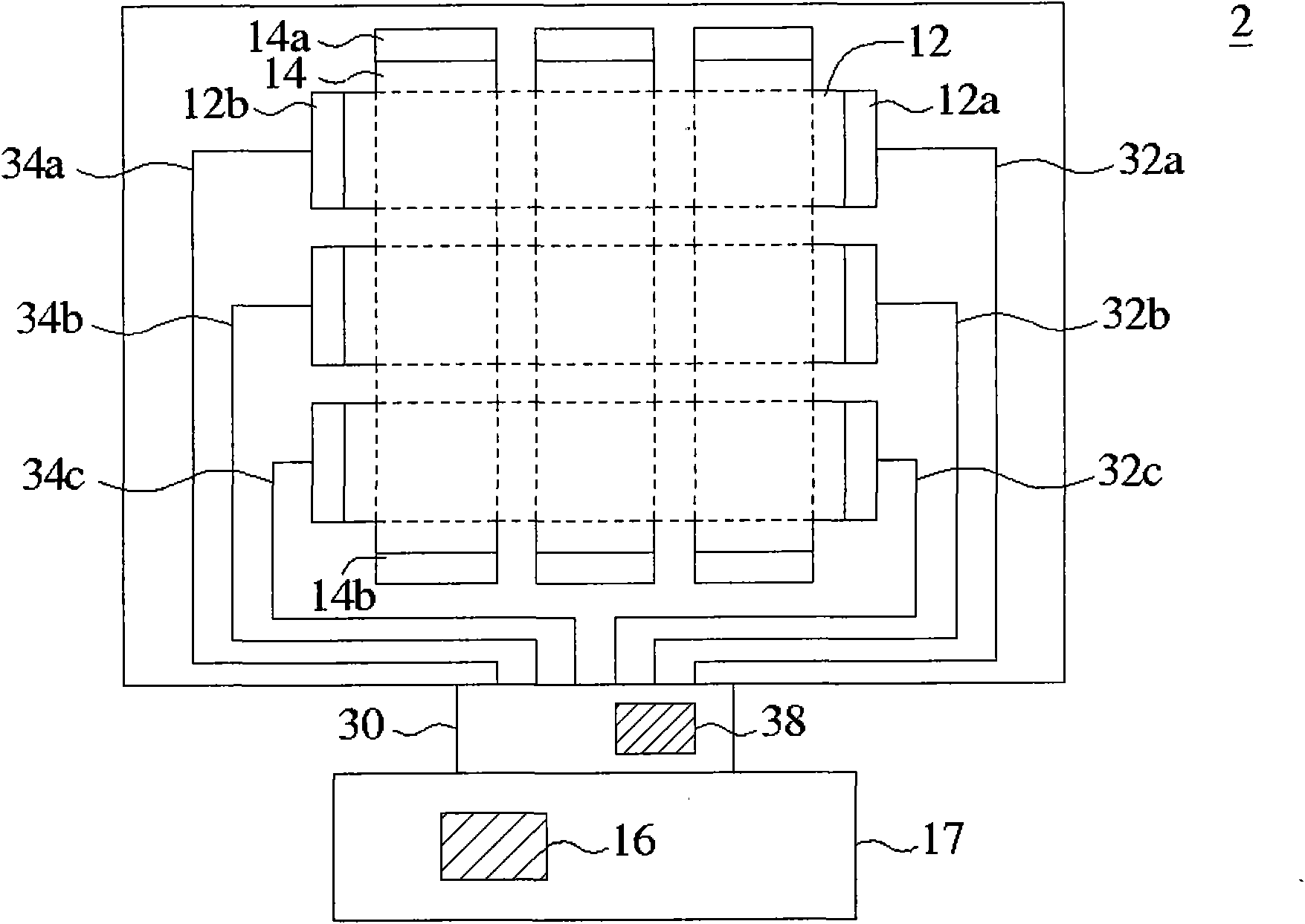

[0013] Please refer to Figure 1A , 1B , which is a schematic diagram of a matrix touch panel according to a preferred embodiment of the present invention. As shown in the figure, the matrix touch panel 1 includes a plurality of first sensing electrodes 12 , a plurality of second sensing electrodes 14 , a control circuit 16 and a compensation circuit. To simplify and clarify the schema, Figure 1A , 1B Only three of the first sensing electrodes 12 and the second sensing electrodes 14 are shown in the figure, and the configurations in which the first sensing electrodes 12 and the second sensing electrodes 14 are respectively connected to wires are shown in the two figures respectively. The first sensing electrodes 12 are arranged parallel to each other, for example extending along the horizontal direction of the drawing. Each of the first sensing electrodes 12 has a first end 12a and a second end 12b. The second sensing electrodes 14 are arranged parallel to each other, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com