Jacking structure of tower crane and hydraulic system and jacking method thereof

A tower crane and hydraulic system technology, applied in the field of hydraulic systems, can solve problems such as inability to run synchronously, and achieve the effects of solving inability to synchronize and overcoming poor results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

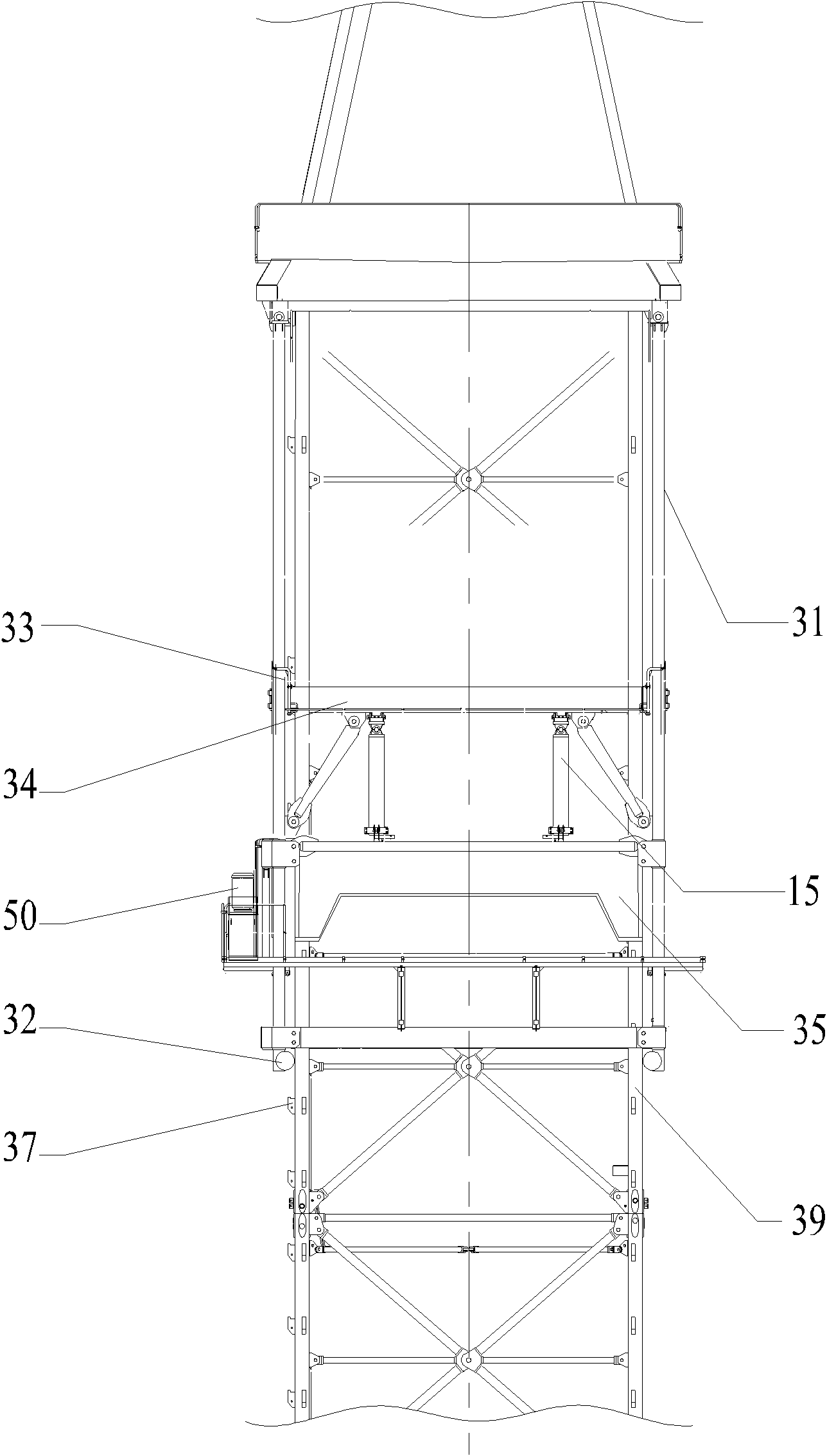

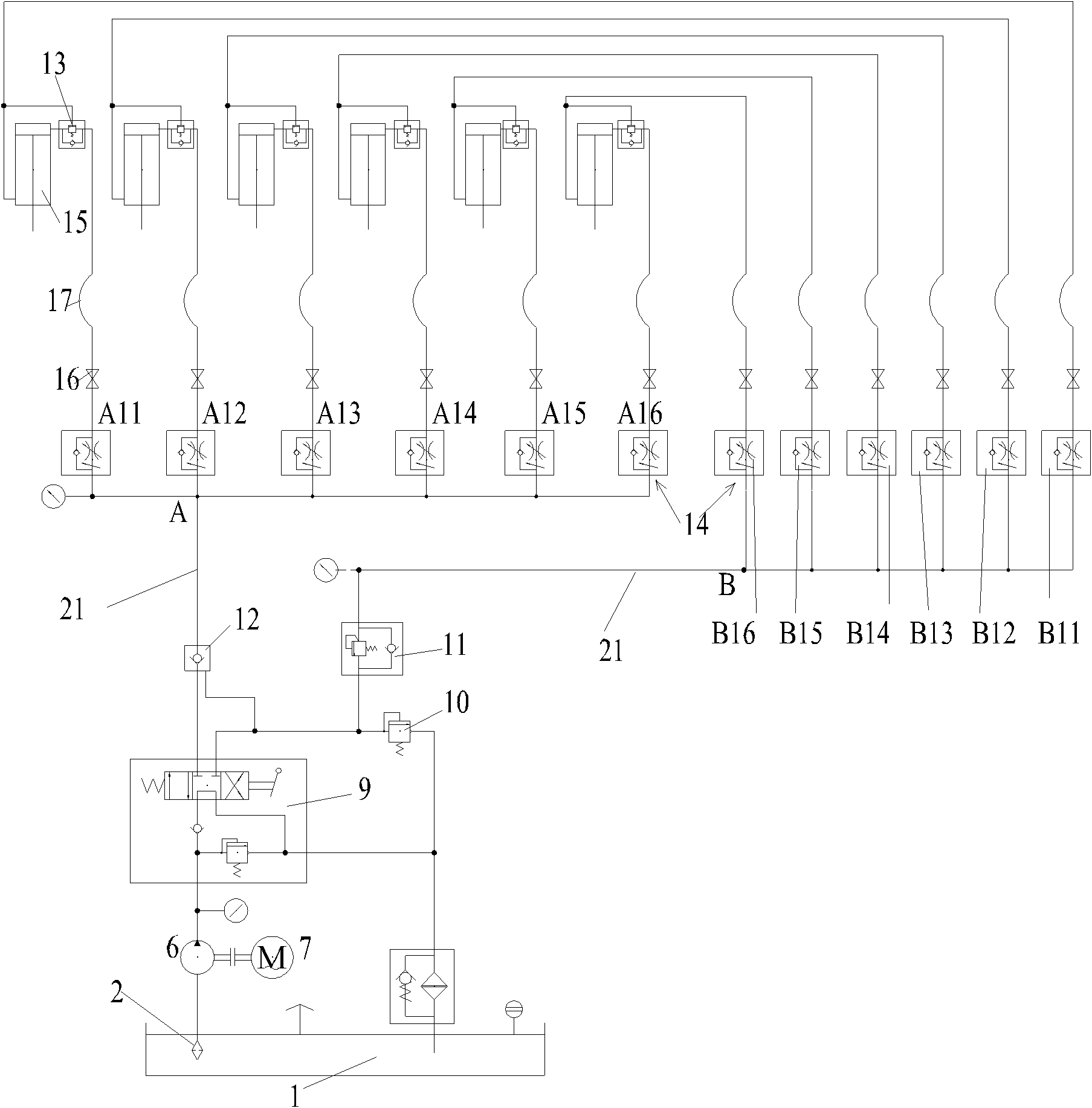

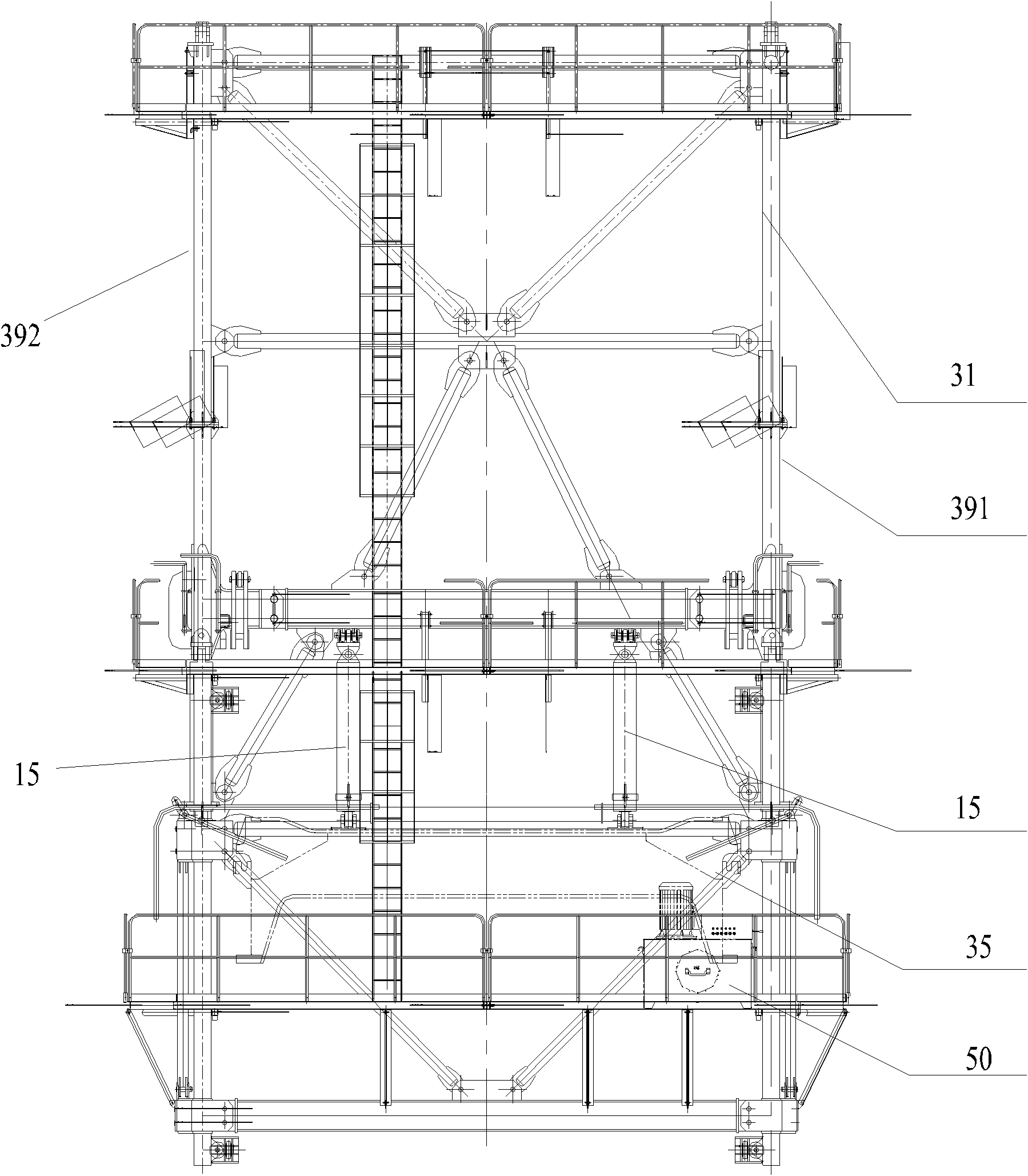

[0031] Such as figure 1 As shown, the tower crane according to the embodiment of the present invention drives the climbing frame 31 of the tower crane to lift on the tower body 39 of the tower crane through the hydraulic system of the jacking structure, for example, the climbing frame 31 is supported and driven by the hydraulic system , lift up and down on the tower body 39 by the guide wheel 32 on the tower body 39 . Hydraulic system comprises a plurality of oil cylinders 15, for example can comprise: two, three, four, six or eight oil cylinders, when adopting above-mentioned number of oil cylinders 15, oil cylinders 15 are arranged easily, when for example comprising two oil cylinders 15, tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com