Material withdrawal apparatus and methods of regulating material inventory in one or more units

A technology of extracting equipment and cooling fluid, applied in the field of material extracting equipment, can solve the problems of FCC unit not working, FCC unit performance and expected output reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

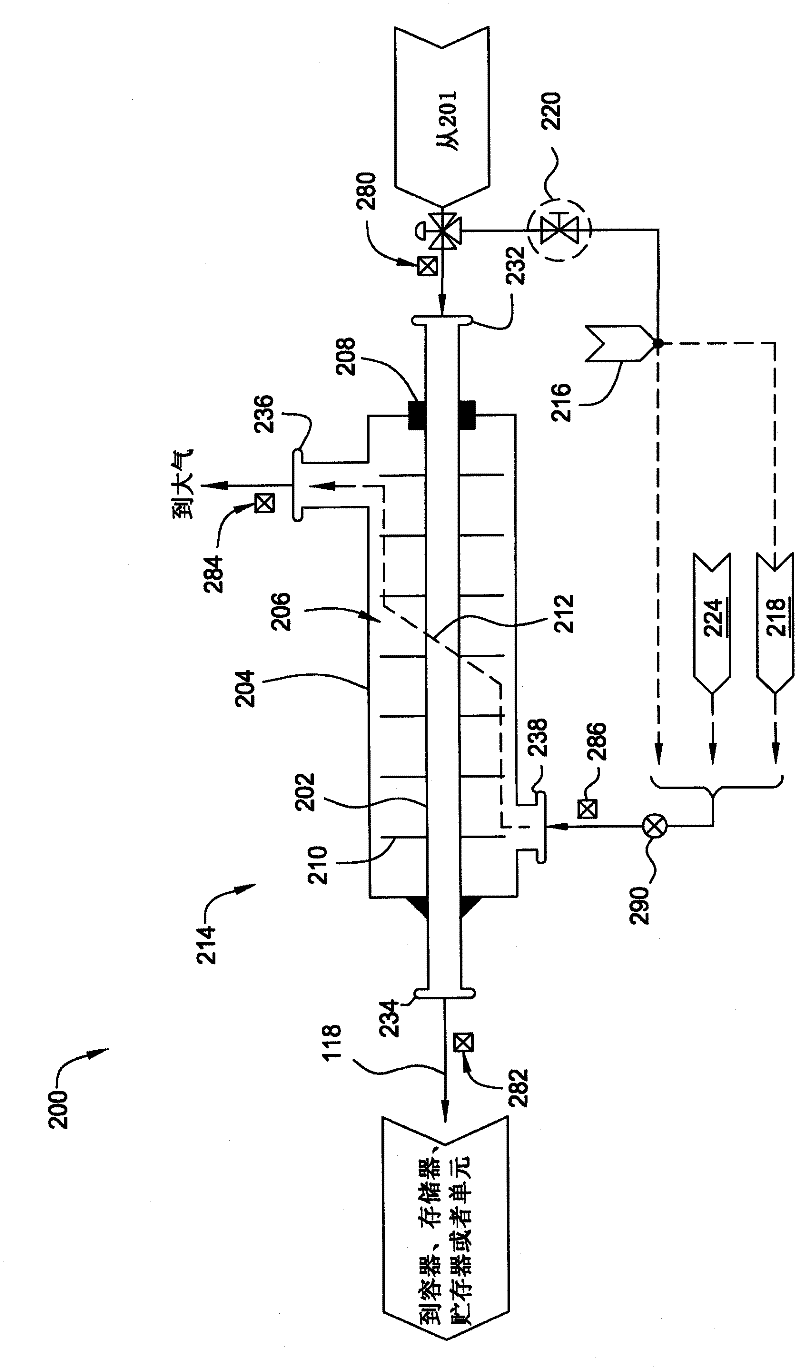

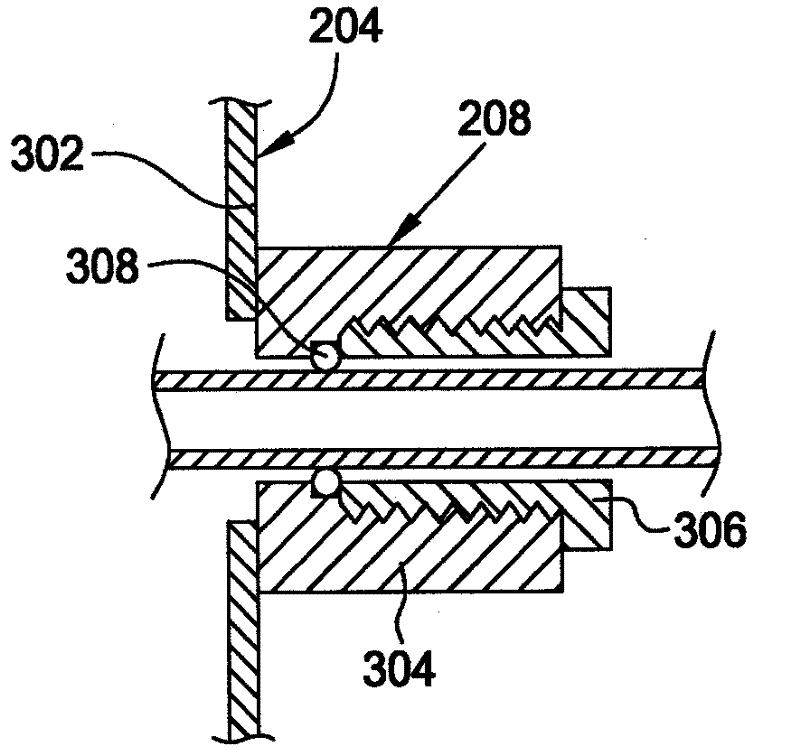

[0024] In the following description, like reference numerals designate like or corresponding parts throughout the several views shown in the figures. It should also be understood that terms such as "top", "bottom", "outwardly", "inwardly", etc. are words of convenience and should not be construed as terms of limitation.

[0025] Reference will now be made in detail to the exemplary embodiments of the invention illustrated in the accompanying drawings and examples. With reference to the drawings generally, it will be understood that the drawings are for purposes of describing particular embodiments of the invention and are not intended to limit the invention thereto.

[0026] When referring to a particular embodiment of the invention comprising or consisting of at least one element of a group and combinations thereof, it should be understood that the embodiment may comprise or consist of any element alone or in combination with other elements of the group. Any element in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com