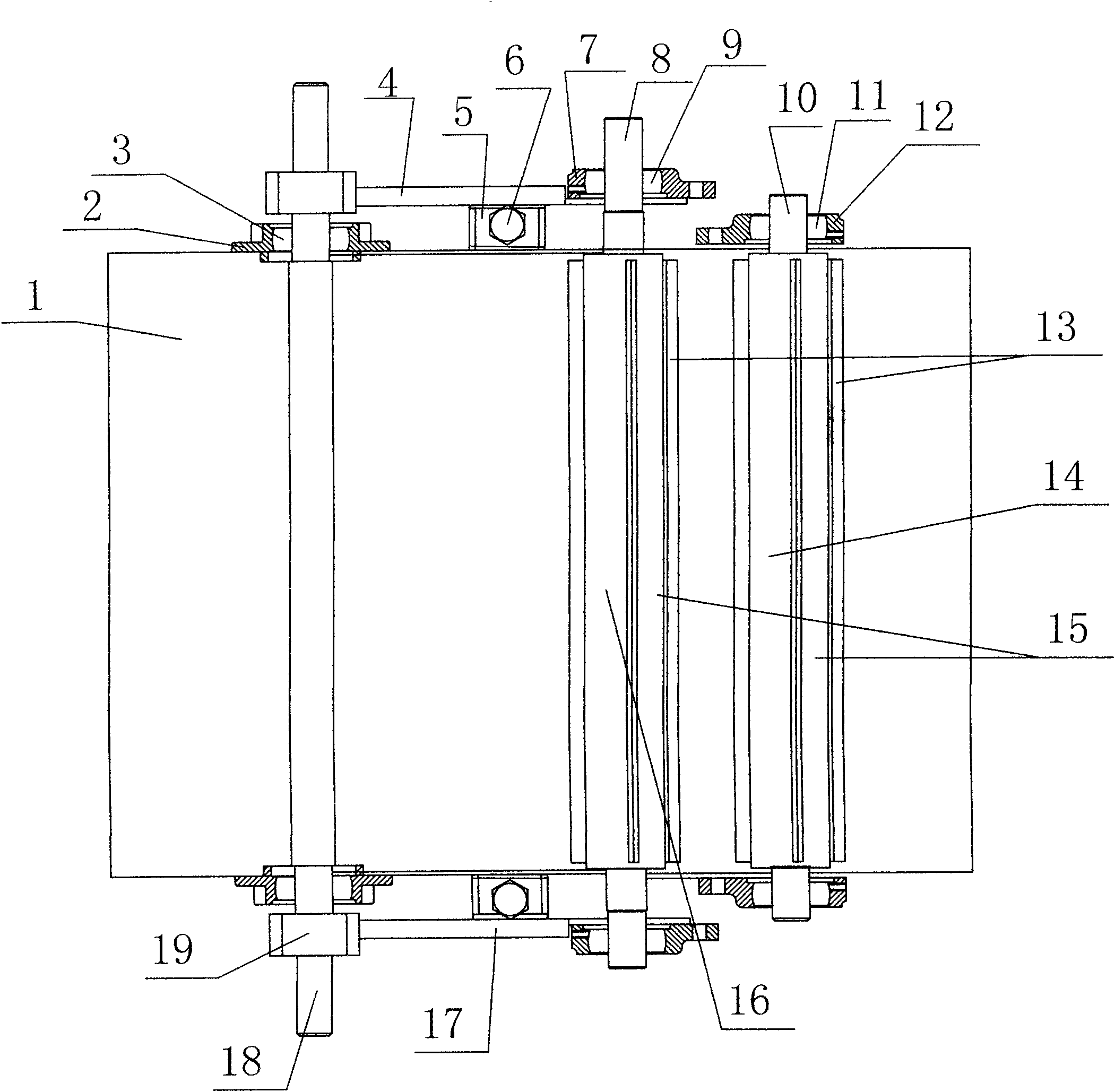

Secondary-cutting floating pick device of self-propelled corn harvester

A picking device and self-propelled technology, which is applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of broken transmission chains, bursting, and twisting and deformation of elevators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

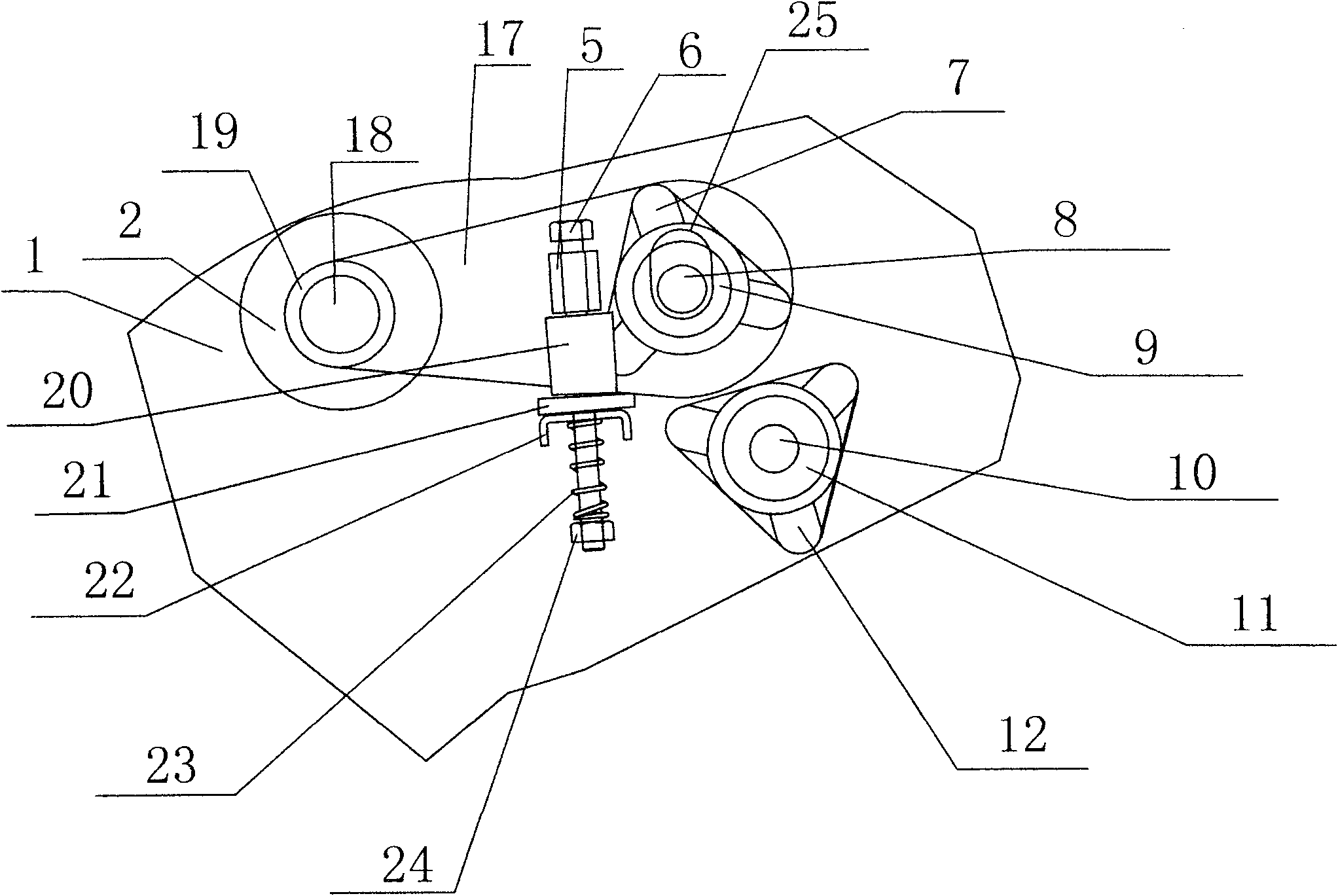

[0011] When corn stalks pass through the fixed and dynamic pick-up devices, due to the adjustable gap between the fixed and dynamic pick-up devices, when the load of corn stalks increases, the dynamic pick-up roller 16 in the dynamic pick-up roller device and the fixed pick-up roller in the fixed pick-up roller device The rollers 14 are squeezed by the corn stalks and tend to separate from each other. The fixed pick-up rollers 14 are installed on the fixed pick-up roller device, and the fixed pick-up roller device is fixed on the lifter shell 1, and cannot move in position. The dynamic pickup roller 16 is installed on the dynamic pickup roller device, and the position of the dynamic pickup roller device is variable. When there is no load, the figure 2 One is determined by the height of the sum of the sleeve 20 and the washer 21, and the other is that when the spring 23 is in the limit compression position under the ultimate load, the free change between these two positions is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com