Rigid mill of screw rod

A powerful milling machine and screw technology, applied in the field of milling machines, can solve the problems that the turning depth and turning area cannot be increased, the work efficiency cannot be improved, and the turning force is small, so as to increase the turning force, increase the turning depth and turning area, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

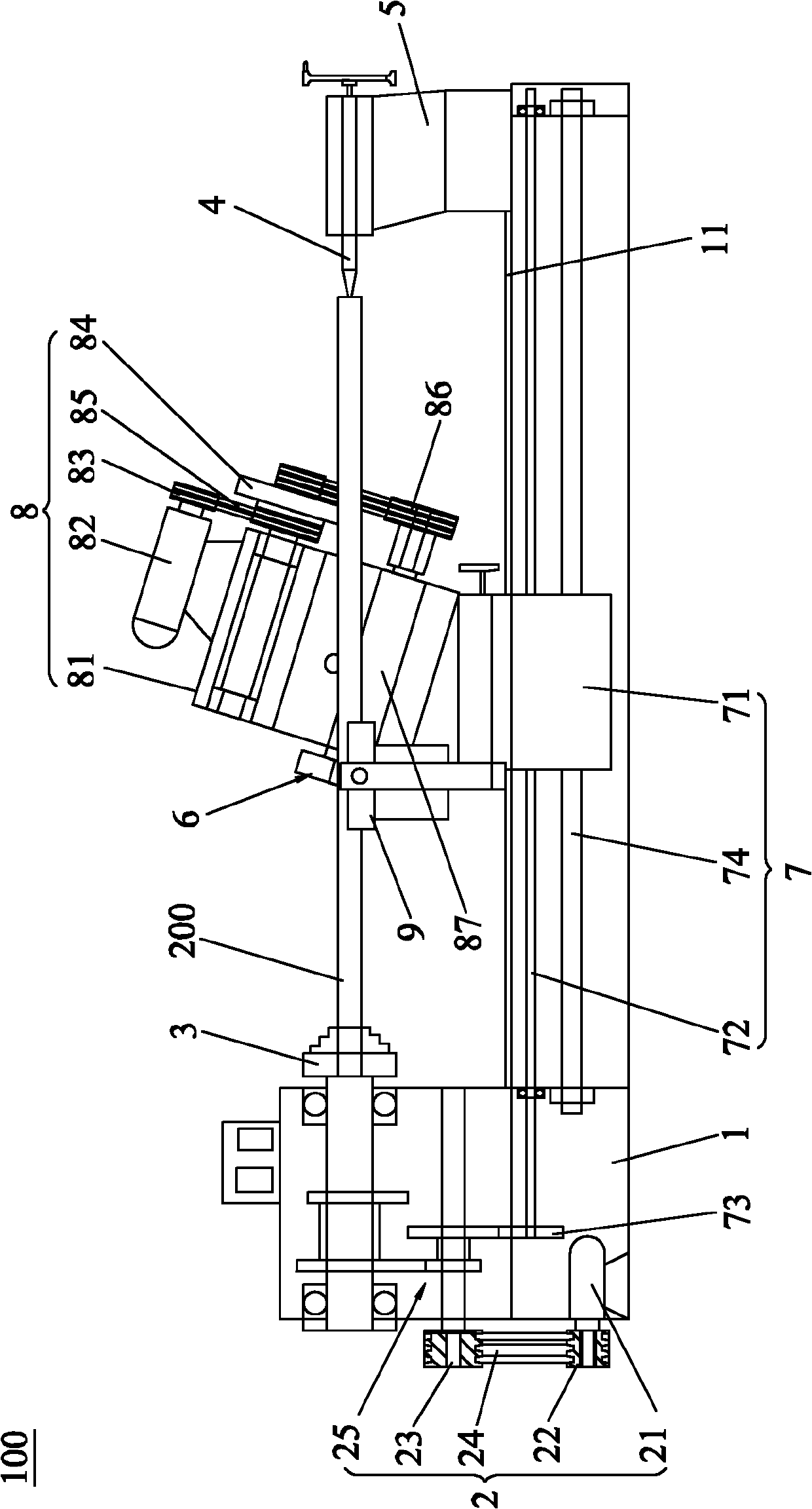

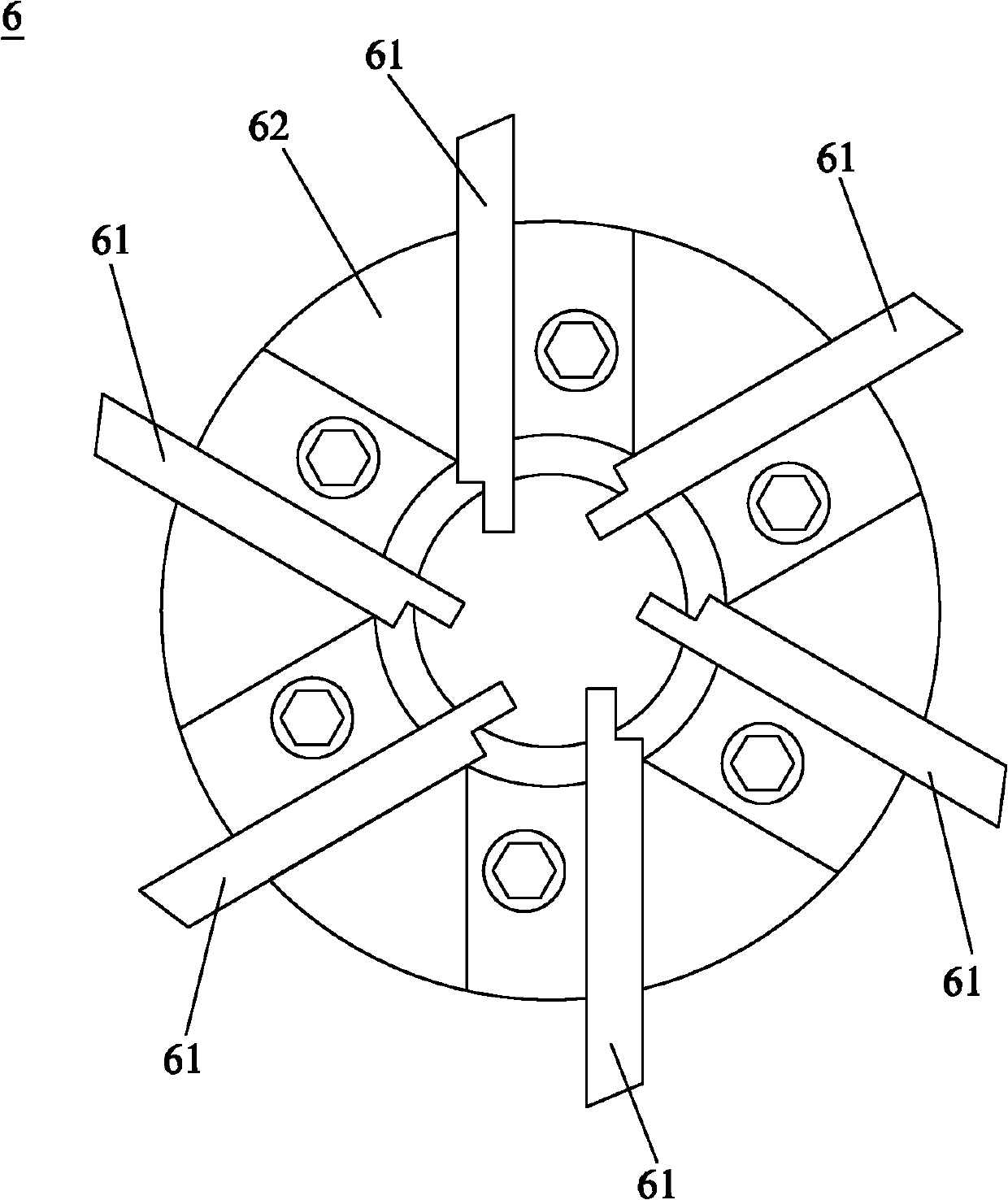

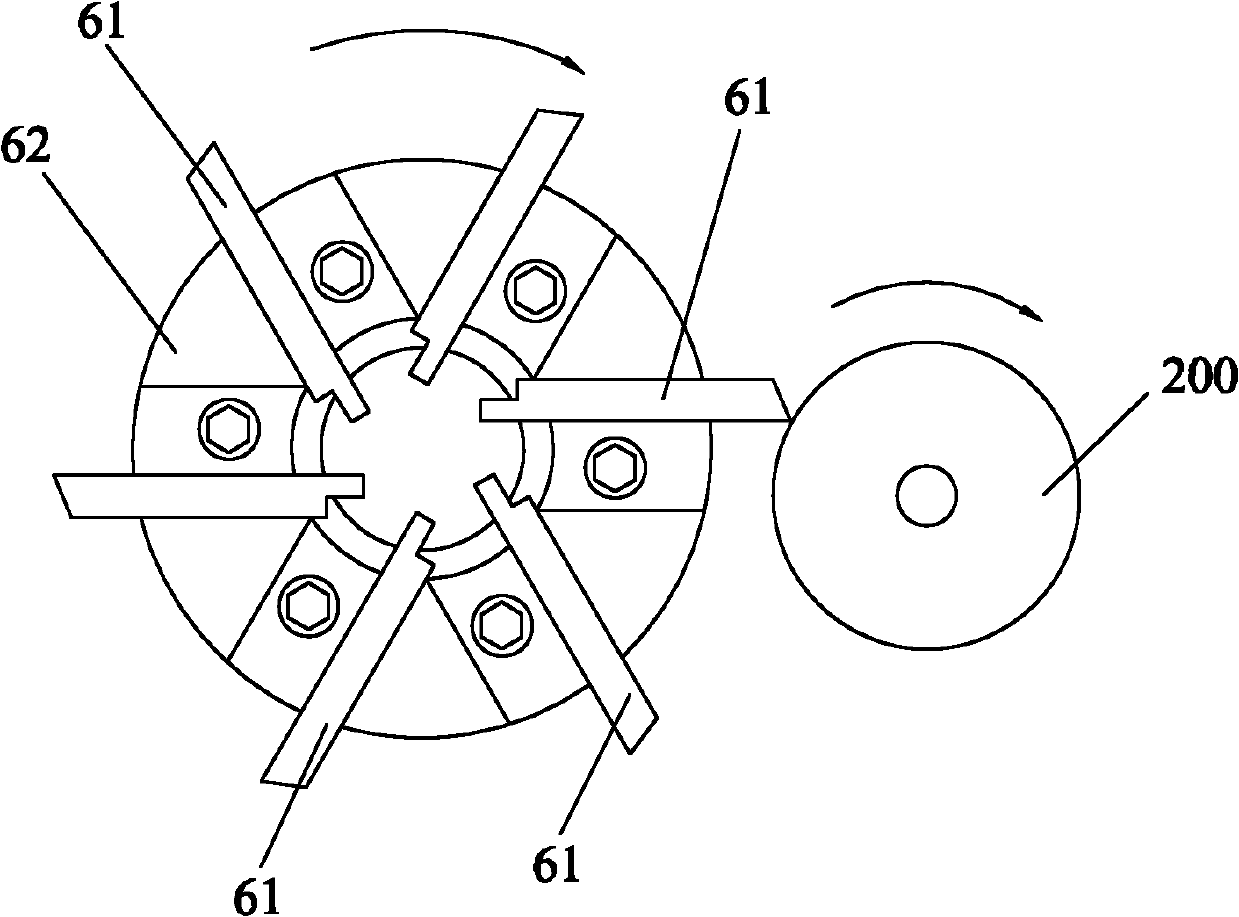

[0018] Such as figure 1 As shown, the screw powerful milling machine 100 of the present invention includes a machine tool body 1, a driving mechanism 2, a chuck 3, a thimble 4, a thimble holder 5, a milling head 6, a milling head moving mechanism 7, a milling head driving device 8, a chip removal channel 9 and control system (not shown). The driving mechanism 2 is installed on the machine tool body 1 and the output end is connected to the chuck 3 , the cylindrical workpiece 200 is placed horizontally, and the chuck 3 is clamped on the left end of the cylindrical workpiece 200 . The thimble 4 is installed on the thimble seat 5 and is in contact with the right end of the cylindrical workpiece 200. A slide rail 11 is provided on the machine tool body 1, and the thimble seat 5 is slidably mounted on the slide rail. 11, so that the thimble 4 and the chuck 3 can clamp cylindrical workpieces 200 of different lengths. The milling head moving mechanism 7 is movably mounted on the mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com