Wide-pressing area belt type calender

A technology of calender and wide nip, which is applied in the direction of calender, paper machine, textile and paper making, etc. It can solve the problems of inability to adjust the pressure, the replacement of soft rolls, and the inconvenience of steel belt replacement, etc., so as to increase the range of the nip , High work efficiency, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

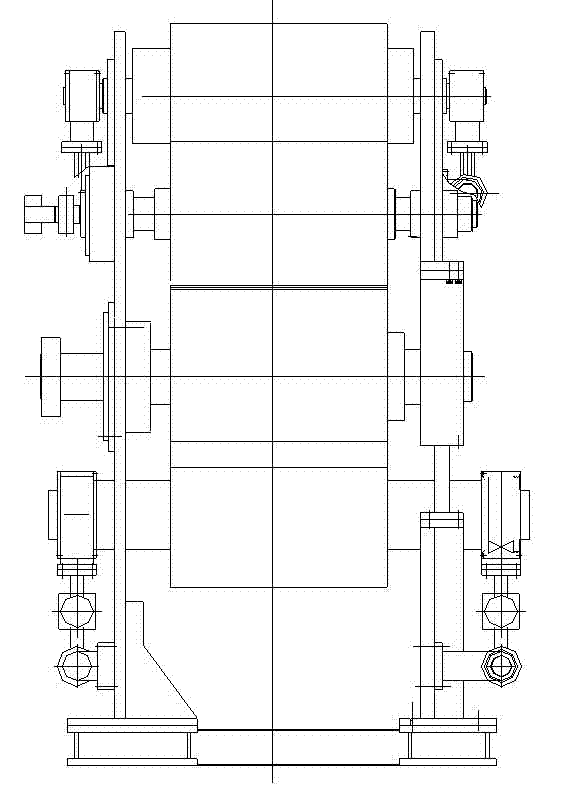

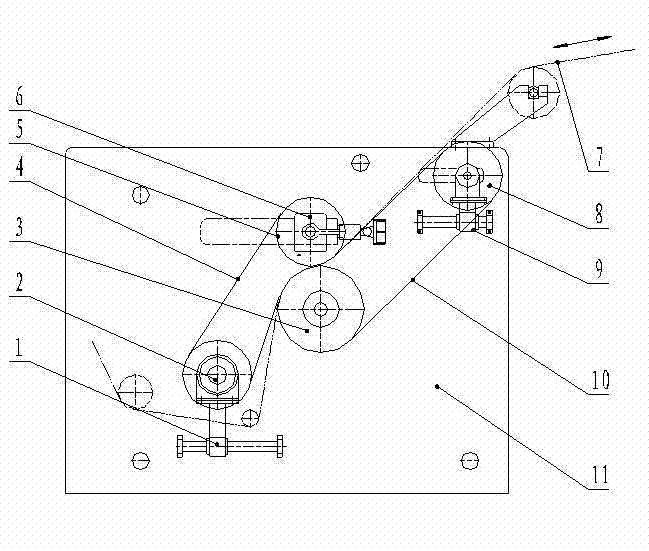

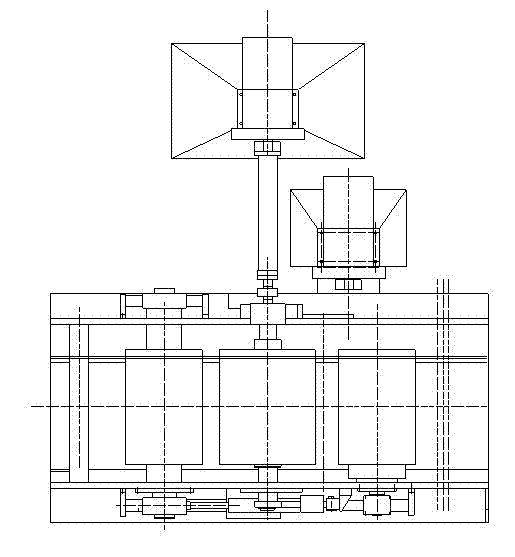

[0012] see Figure 1-Figure 3 , the wide nip belt calender of the present invention, it comprises frame 11, and heat roller 3 is installed on described frame 11, and upper pressure roller 5 is arranged above described heat roller 3, and described upper pressure roller 5 passes through The movable bearing seat 6 is installed on the frame 11; the first guide roller 2 is arranged obliquely below the heat roller 3, and the first guide roller 2 is installed on the frame 11 through the first movable bearing device 1. A first steel belt 4 is surrounded between a guide roller 2 and an upper pressure roller 5; a second guide roller 8 is arranged obliquely above the upper pressure roller 5, and the second guide roller 8 passes through a second movable bearing device 9 Installed on the frame 11, the second steel belt 10 is surrounded between the second guide roller 8 and the hot roller 3; Equipped with horizontal slots.

[0013] During work, the object to be pressed 7 passes between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com