Flexible roller contact type thin strip combined cooling method

A cooling method and a technology of flexible rollers, which are applied in the direction of workpiece cooling devices, furnaces, heat treatment equipment, etc., can solve the problems of uncontrollable cooling end temperature, difficult control of cooling speed, narrow application range of equipment, etc., and the method is simple and feasible, and the surface is clean , good effect of plate shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

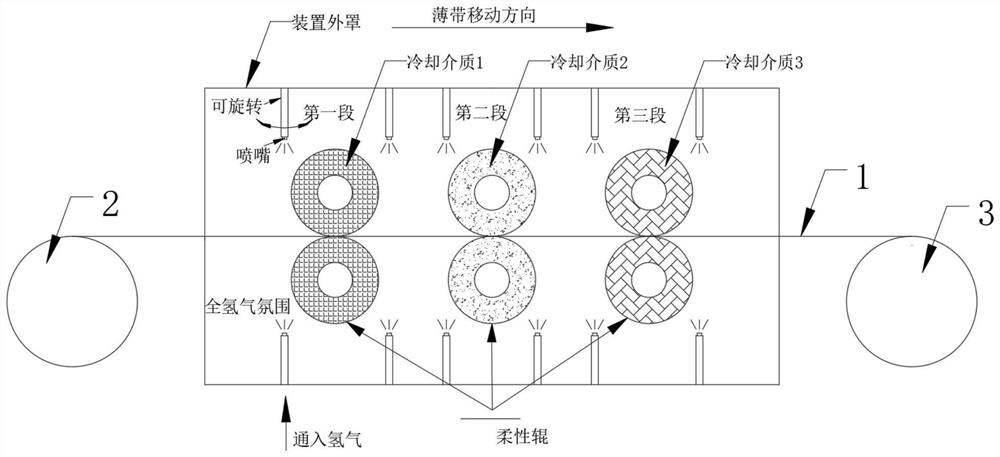

[0032] combine Figure 1-2 As shown, a flexible roller contact type thin strip combined cooling method in this embodiment is:

[0033] 1. The 201 stainless steel ultra-thin strip rolled to 0.04mm by the asynchronous reversing rolling mill 1 is rolled by the coiler on the coiling side of the rolling mill, and the rolled ultra-thin strip is placed at the entrance of the flexible roller spray composite segmented cooling device On the unwinding device 2 at the end, take the movable end of the ultra-thin coil and weld the lead tape. The lead tape is a 1mm thick ultra-thin strip that needs to be cooled. The cooling device is connected to the rewinding device 3 on the other side of the cooling device, and is curled on the rewinding device 3 for more than two turns to ensure that it will not fall off when tension is applied to the ultra-thin belt subsequently.

[0034] 2. The ultra-thin strip of 201 stainless steel with a thickness of 0.04mm adopts 7-stage combined cooling. The cooli...

Embodiment 2

[0041] combine Figure 1-2 As shown, a flexible roller contacting thin strip combined cooling method in this embodiment is as follows:

[0042] 1. The 304 stainless steel ultra-thin strip rolled to 0.005mm by the asynchronous reversing rolling mill is coiled by the coiler on the coiling side of the rolling mill, and the coiled ultra-thin strip is placed at the entrance of the flexible roller spray composite segment cooling device On the unwinding device at the end, take the movable end of the ultra-thin coil and weld the lead strip. The lead strip is a strip of the same steel grade as the ultra-thin strip with a thickness of 1mm that needs to be cooled, and the lead strip is passed through the entire flexible roller. The device is connected to the rewinding device 3 on the other side of the cooling device, and is wound on the rewinding device for more than two turns.

[0043] 2. The ultra-thin strip of 304 stainless steel with a thickness of 0.005mm adopts 3-stage combined co...

Embodiment 3

[0050] combine Figure 1-2 As shown, a flexible roller contacting thin strip combined cooling method in this embodiment is as follows:

[0051] 1. The 316 stainless steel ultra-thin strip rolled to 0.05mm by the asynchronous reversing rolling mill is coiled by the coiler on the coiling side of the rolling mill, and the coiled ultra-thin strip is placed at the entrance of the flexible roller spray composite segmented cooling device On the unwinding device at the end, take the movable end of the ultra-thin coil and weld the lead strip. The lead strip is a strip of the same steel grade as the ultra-thin strip with a thickness of 1mm that needs to be cooled, and the lead strip is passed through the entire flexible roller. The device is connected to the rewinding device on the other side of the cooling device, and is wound on the rewinding device for more than two turns.

[0052] 2. This ultra-thin strip is 316 stainless steel with a thickness of 0.05mm, and adopts 12-stage combin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com